Everything posted by Patcon

-

1977 280z clock issue #xx of yy

What is it?

-

Distributor drive gear

I was think a roll pin located that gear. Do you have some pictures?

-

Z's on BAT and other places collection

I am seeing some prices coming down in real estate, salvage cars and cars in general. I think this reflects higher interest rates and lower demand. Almost 50k is still a good price for a Z car.

-

- just got my '72.

Datsun 510 guys sometimes use the front ZX struts as a cheap upgrade

- L20b Cody's Goon

-

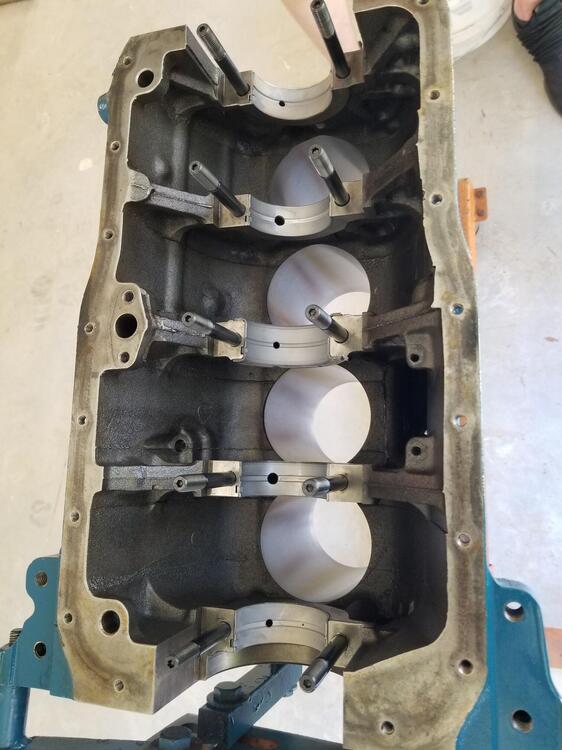

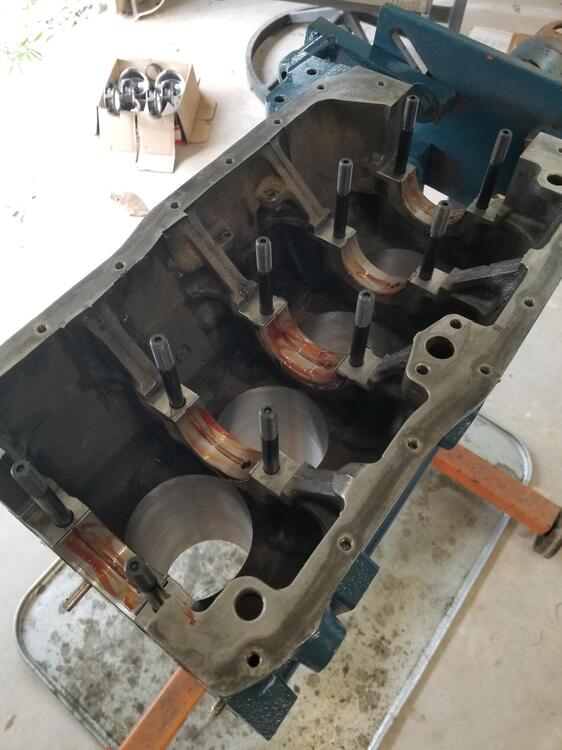

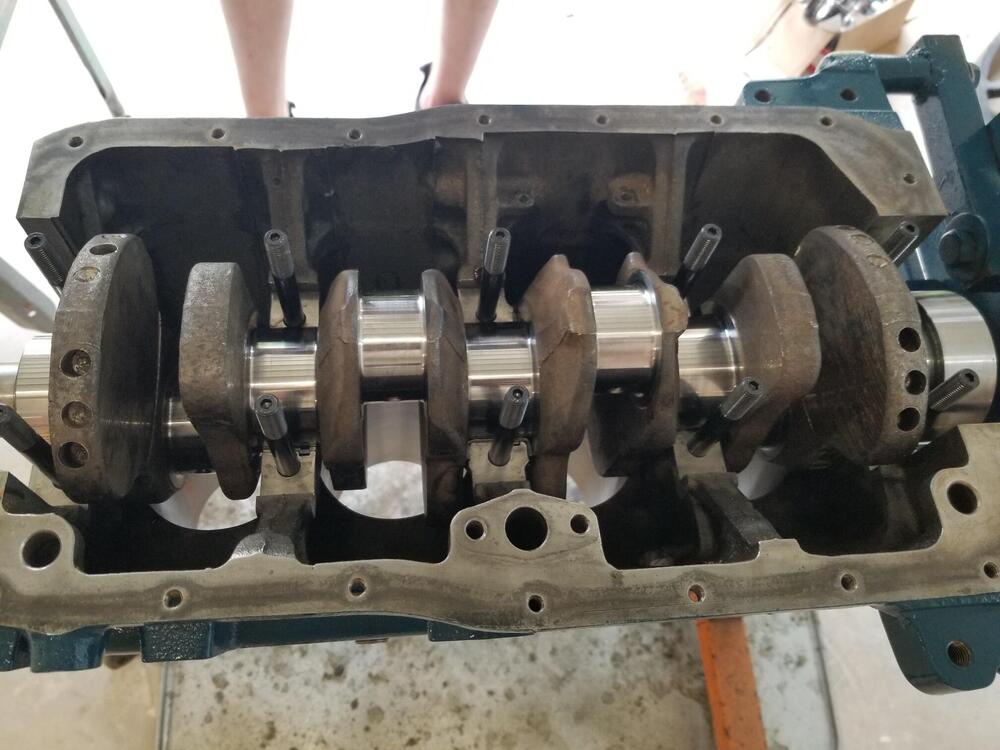

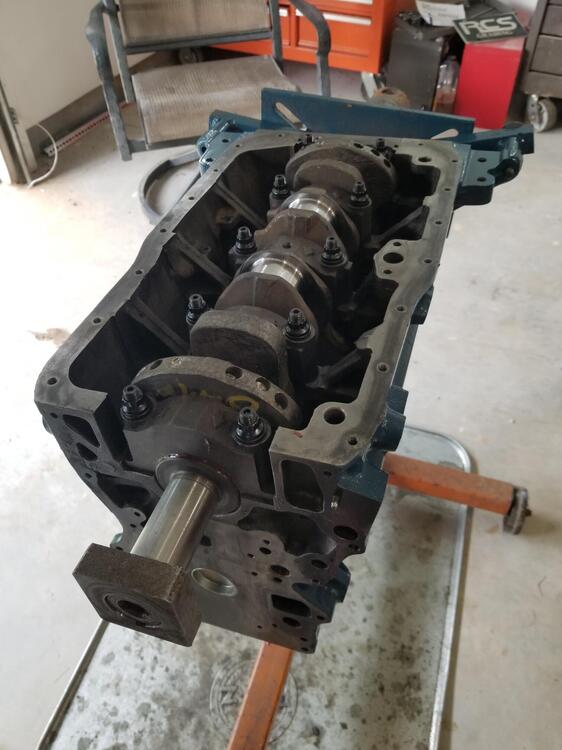

L20b Cody's Goon

We worked on the motor some more last weekend Checked ring gaps All the studs in We checked all the clearances with indicators and verified with plastigage Right now the thrust bearing is pretty tight. I'm not sure we have any clearance. I think we're looking for 0.05 mm. We'll see... @Captain Obvious

-

1983 280zx turbo engine

So what changed?

-

Reuse OE head gasket add some copper spray.

I know the BMW's I have worked on have valve tap when they have sat for months. It goes away with a little light driving

-

1983 280zx turbo engine

Is it possible the water jackets are contaminated now and that is throwing the test?

-

Reuse OE head gasket add some copper spray.

That was my thought too. A crack somewhere else, other than the head gasket surface. Could be head or block...

-

Share 16 x 8 wheel pics 0 offset and negative offset

Also the car you like in the video at the 2 minute mark has custom fit coil overs. Which is why they can run this really wide rim with 0 offset. It will rub the stock strut at that width. Most people run 7 in wheels on a factory suspension. I have run 245s on wheels smaller than 7 inches so there are lots of variables.

-

[2022] What Did You Do To/with Your Z Today?

I'm hoping one day you'll paint that air dam...

-

Share 16 x 8 wheel pics 0 offset and negative offset

And those are really wide wheels to get under stock fenders if you don't have coilovers. If you are gonna run a stretched tire look they might work but I doubt it otherwise

-

Is this the shining knight to conquer the dreaded spindle pin?

Steve, I have a pin puller I could ship you if you thought it would help. Acme thread, bearing, etc. Also which Induction heater are you looking at exactly? I was shopping for this just last week...

-

ZCON 2022 Roll Call

Don't know that I will be able to go to that one. Not sure Canada will let me in... or is that California?

-

ZCON 2022 Roll Call

Where is 2023 going to be??

-

hot water to manifold?

I also believe it was to prevent iceing in the carbs

-

Need clutch disc, not kit

If it is in neutral and the clutch isn't depressed then I believe the front portion of the input shaft is spinning

-

76 280Z Rust Issue

The floors and that rail are structural to the car. They are not merely cosmetic...

-

280z control arm

You could do it up on ramps or blocks. Just be sure the car can't roll off on you!

-

Z's only a mother could love thread

It's a shame, that was technically hard to do unless the hood is fiberglass...

-

Windshield Polish

I have actually had pretty good results buffing glass. Deep scratches don't come out but it does tend to remove light scratching and makes scratches less evident. Buffing compound and polishing compound are just high grit liquid sandpaper. I'm sure the grits are every bit as hard as glass.

-

280z front bumper ends

I would dig the remainder of that bolt out of the bumper and either epoxy a new bolt in or use a urethane adhesive caulk

- 240ZBUILTBYME 1971 240z HS-001063 Project Georgia

-

Strut insulator

The rubber on the one on the left also appears to really brittle. The right one might be that way too but the left has lost a lot of the rubber rim

Subscriber

Subscriber