Leaderboard

-

conedodger

Free Member20Points12,640Posts -

Patcon

Subscriber

Subscriber 13Points11,182Posts

13Points11,182Posts -

zKars

Subscriber

Subscriber 8Points3,779Posts

8Points3,779Posts -

JDMjunkies.ch

Free Member8Points641Posts

Popular Content

Showing content with the highest reputation since 12/07/2025 in Posts

-

What size bolts will fit?

6 pointsHere are the thread rules. Again. For any hardware you are likely to encounter. 4 x 0.7 5 x 0.8 6 x 1.0 8 x 1.25 10 x 1.5 - bolts that thread into the engine block. Trans, head, brackets, 10 x 1.25 - All other M10 bolts, ie suspension and body are 1.25 12 x 1.25 - wheel studs, front spindle to steering arm, trans mount (later), TC rod ends, Flywheel , spindle pins 14 x 1.5 - diff strap bolts, front control arm pins 16 x 1.5 - Crank bolt 20 x 1.5 - Rear Stub Axles Threaded pipe fittings are all BSPT, A/C and EGR excluded. There is a 1/4x28 SAE thread somewhere for you to find as a test. There are 7/16-20 SAE too. Another test. And what the heck is up with those short fat rear control arm bushing bolts? And why do I have 2 or 3 dozen of them? The first 7 on the list are the ones you should have taps and dies for on hand at all times. Better yet the thread restoring kind, not the thread making kind. Print this out and post it on the shop wall.6 points

-

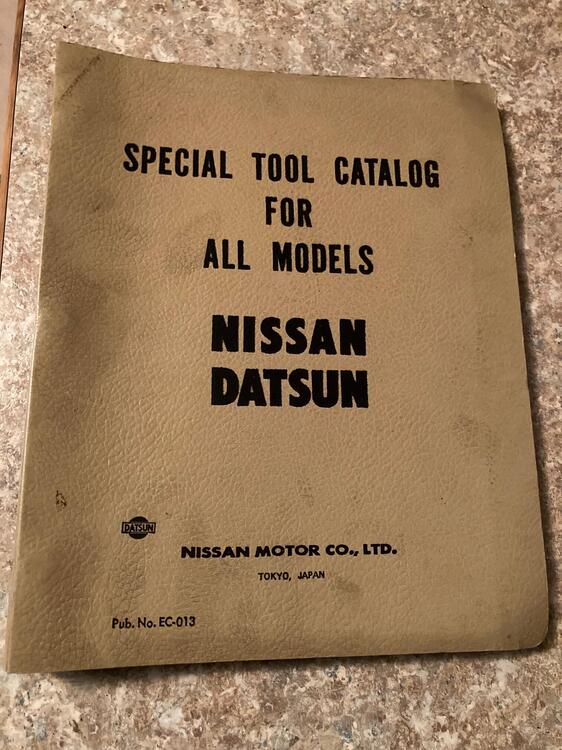

Datsun Tools

5 pointsRecently a guy on FB posted he had bought a bunch of Datsun tools and tool boards. He has them all cleaned up and mounted on the garage wall. Makes a nice display. I have the Special tools manual from 9/69 and a couple of mechanic seat covers that I really have never seen before. Do any of you have any info on the seat covers?5 points

-

Let's show vintage racing pictures. I'll start.

4 points

-

Who's been MIA?

3 pointsPoppin' back in for a bit, although @conedodger and @Yarb see me quite a bit in The Rusted Zed Pub section. 😎 🍻 It's been a few years since I've spoken with Gary Moisant but I'm pretty sure he's still around up in Oregon. Can't get him away from the race cars! The last time I spoke with Keith @2ManyZs (many, many years ago) he was having some health issues. I reached out once by email a few years ago but never heard back. Edit: I reached out again to Keith yesterday and he is still around, still has his Z but it is still unfinished. So, I popped back in here because I ran across something the other day that made me think of this thread. I saw my old Z for sale on Marketplace!!! She's about an hour's drive away and actually less than a mile from my mother-in-law's place! Paint still looks good (which I'm pretty proud of!) but that four-letter "R" word has started coming back with a vengeance! The guy who is currently selling, bought her not too long ago from the guy I sold her to. I stopped by yesterday on my way home from Austin, TX to see her, talk to her, and wish her well in the next part of her life. Still has good bones, but the level of repair is far more than I'm willing to tackle at this age and stage of my life. It was cool to see her again and I can't say I didn't shed a tear or two... We did go down the roadster route for a few years but not anything from Datsun. We did the Miata thing. Cool, fun little car that was a blast to drive. Helped that it was already set up for autocross which made street driving an absolute blast! Top down every single drive, even if we got caught in the rain (as long as you stay moving...)! But alas, as the wife and I both start looking toward retirement all of the toys have been traded up for a large center console boat for fishing down on the TX Coast! Grandkids are on the way and life's focus has just changed. The Z will always be a part of my life and I will die loving the sleek lines of the S30s, but I don't think there will ever be another one in our garage. Add it to the list of cars that "We should have never sold!" 😉 Y'all keep the rubber down and the RPMs up!3 points

-

My two swiss S30Z Fairlady Restoration build thread

I've been traveling a lot recently, and been dealing with life, but I still managed to collect some cool stuff: I got hands on this cool vintage NISMO enamel sign from Japan: And this cool Poster, which shows a works GTS-II race car. The seller says he got it from a racing shop called Iwashita racing in Shizuoka, many years ago. According to Alan, it shows SCCN works car from the first round of 1972 Fuji Grand champion series on the 20th of March, with driver Kazuyoshi Hoshino. I also found this Dutch 1971 Datsun Advertising magazine. Usually I don't collect documents from other countries (there's just too many), but this one is special, because it shows an EU-spec prototype car. If you look closely, you will see the Fender-top mounted blinker / turn signals and the Rob Janssen homemade front spoiler, which led to the development of the OEM front spoiler for European cars by Nissan. Then I got a reproduction of the MK-1520 ZC car radio manual and a correct Swiss 1972 service / Warranty booklet for my car. After a bit of a search, I also managed to get this cool Nissan Oil Can: With the Elephant oil logo from the 240Z oil filler cap: I also got gifted a Center cap from a friend. Not the correct one for my car, but who am I to turn down freebies? I also found a set of NOS OEM FS5C71A transmission "monkey motion" shifter bushings. The original ones of mine were worn out, and I had them replaced with some red aftermarket ones, but these will definitely look better. Then I'm constantly on the hunt for the missing tools of the Datsun / Nissan tool boards, which I acquired recently. Luckily they pop up sometimes, and recently I got a bunch of missing ones: There are still quite a few missing, but 2/5 tool boards are complete now, and the remaining ones are filling up quickly. I'm currently awaiting more deliveries, so expect another update soon. Oh, You may have noticed that I've also reorganized my workshop and garage a bit for better usage of space.3 points

-

Z's on BAT and other places collection

Well... it started life at Pierre's Z... saw it in 2001 at the Motorsports Auto Show. The best looking Z Convt. conversion I had seen. The body lines were beautiful..3 points

-

What's this part?

3 points

-

1973 Rebuild

3 points

-

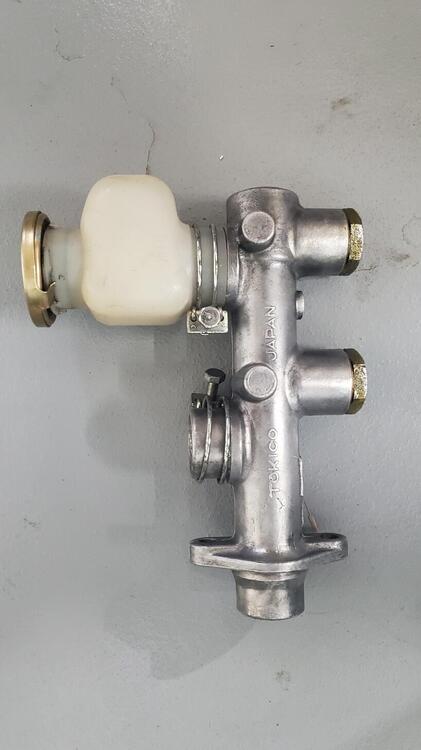

Brake fluid leak at master

3 pointsUpdate for all of you. We very may be in business here and you were all right - the hydraulic line was crooked/not fully seated and once I took it out and reseated it, the leak was gone. Again, I still don't understand how it didn't leak over the course of 6 years and thousands of miles, but I guess that was a good thing. I am going to bleed the brakes tomorrow just to be safe but I did bleed the master after all of this and the pedal feels good. Here are pictures of the line screwed in before, the flange/nut's condition when I took it out this evening, and how the cylinder looks now with the line in straight.3 points

-

1971 HLS30-14938 "Lily" build

3 pointsI also got the tool covers from resurrected classics and got them installed A little nerve racking to bend the plastic hinges to mount them3 points

-

240z turn signal lights

3 pointsS30 parts are rare and expensive. Not enough competition or volume of sales to keep the price down.3 points

-

Duffy's 1/71 Series 1 240z build

2 pointsFinally got my exhaust finished. With the kenmeri header mated to my Fujitsubo exhaust. There was a small gap between the flanges. Designed up a small spacer. This is 316 stainless.2 points

-

My two swiss S30Z Fairlady Restoration build thread

Yesterday, the postman delivered a big package from Japan again. This time with a load of cool documents. The first one (Bottom right) is the Race and Rally preparation manual. I bought this one for a friend, since I already own one. But it's always cool to see those. The second one is a combined S30S(A) / GS30S(A) brochure for the standard Fairlady Z / Z-L and the 2by2 versions. See also Color samples at the bottom right: For whatever reason, one of the Japanese lots included a US-Market 240Z Brochure. Not something I would usually buy, but since I didn't have it in printed form yet it's cool to have it anyway. From the Japanese market again, I got this Fairaldy Z / 240 Operation manual, which also includes the Z432 versions. These are particularly useful to find some details of the interior for my knowledge posts. This is the later version that also covers the ZG and other HS30 variants (the early versions only covered the Z / Z-L and Z432): Then I got two of the Japanese marked fold-out Fairlady Z sales brochures. It's basically a brochure on one side and a ZG Poster on the other side. I was buying one, when a second one was included in a Lot of documents. Once I got them, i realized that i already had one, So now i end up with three. But, I intend to frame one as a Poster and I realized that there are different versions. Both the Material (paper-weight) and print is different: For me no doubt the coolest item is this Nissan Racing school brochure: With the Checkman Sponsored GTS-II Works car on the back. Especially this version of the car with the "Batmobile" rear aero. I just love everything about it. The sponsoring, the aero, the livery. Another Magazine was the "Nissan Graph" Customer magazine from April 1985. Which also included some racing school details. I'm working on a knowledge post about this, that's why I started to collect some information about it. One general 1971 Japanese Nissan brochures also included the ZG: And the general lineup on the inside. I guess this magazine was issued at a Car show in 1971 or at the dealerships? It also included some cool drawings of the 216X Concept car: Another similar brochure (without date) from Nissan Tokyo, which again shows the ZG and some other nice cars: On the inside you find the lineup from that time, but with a regular Fairlady Z and Z-L shown. Another cool book is the J's Tipo Fairlady Z Archives (002). J's Tipo is a Japanese car magazine, and this book is basically a collection of all their Fairlady Z related stories from various years, compiled in one book. After I met Morita san, the Author of the Fairlady Z Story and History books, in Japan recently, I had to get "Volume 2" of the book. I've owned Vol 1 for a long time, but never the second one, since it wasn't so relevant for the S30. But now I had to get it :-) Then i also got this Jack and tool stowage reproduction Sticker from Germany. I had this Genuine Datsun Parts sticker for a long while and always wondered how I can present it. When I found this piece of Aluminum sheet, I got the idea to make a sign out of it. So I cut the aluminum. And then put the sticker on it. So I ended up with this cool sign. And found a good little Spot for it: I also found a nice place for the NISMO sign, but it looks a bit small on this big wall, next to the huge Datsun sign. I have some projects planned for the next week and hope I can get back working on the car itself, so stay tuned for some updates, soon.2 points

-

Let's show vintage racing pictures. I'll start.

It's unfortunate so many cool looking concept cars don't get built or the coolness gets lost in the transition to production line2 points

-

Z's on BAT and other places collection

That's what we did with boats, river racing. Put spray paint marks on the inside of the highway guardrails along the river. 13 hundred and 20 feet, run what you brung was like a Bible verse I'll never forget.2 points

-

My two swiss S30Z Fairlady Restoration build thread

Wonderful stuff you have obtained, I envy you! In addition I have never seen tools boards, wall mounted tools are so cool. Thank you for your gift “tools manual” which is replicated nicely, I think I have the lost pages in digital format when one of my friend on facebook kindly gave me. So we can share it. Kats2 points

-

Z's on BAT and other places collection

From the looks of it, it will break $46k but I doubt they will recoup the investment2 points

-

My two swiss S30Z Fairlady Restoration build thread

If you follow me on social Media, you might have noticed that I spent the last 10 days in Japan with my fellow S30.world friends for a very special once-in-a-lifetime experience. I'll post multiple detailed stories on this website soon, but I still need to process it all in my brain and go through thousands of photos. What I can show you already is what I brought home from Japan, aside from all the business-cars and fresh S30.world clothing (not pictured): First, a set of Papers with the "Nissan logo": Those are the ones that Nissan dealers usually put in new cars to protect the carpets. We had them at our Car show in Japan to protect the floor from tire-marks. As we had a lot of them leftover in the end, I thought i stuff two in my suitcase :-) I also got various stickers. From the old NISMO logo stickers, which I bought in the Nissan HQ Gallery in Yokohama, to a handwritten Kanji-version of my name, to various stickers of the event, and a sticker that me a local Honda dealer gave when we checked out their cars. Some went of course directly onto my new "Hall of Fame": I was also very fortunately to buy one of the very last RS-Mach "Ura Mach" steering wheel from the maker himself. I have planned a detailed story on this blog about the Mach steering wheels, so stay tuned, if you want to know more. He sold all the remaining ones he had on this very day and doesn't plan to make new ones. I also came home with a lot of Magazines and catalogues. From the Protec catalogue to the Nostalgic hero (showcasing the new NISMO DOHC head, which we would be able to check out the next day), to the nice Motorfan Fairlady special edition which I was gifted by Endo-San, To the new Motor magazine 70th anniversary edition by Editor Morita-san, which joined us during the first days of our trip. At RS-Watanabe we got gifted with a nice bag that also included a lovely box with their iconic Watanabe 8-spoke wheel as a miniature keychain version. Lovely! From Morita-san i was gifted the lovely pin in exchange for a document I gave him and from Jeff we got gifted some ZCon keychains and a group Z sports car club Bolt tray. The bolt-tray went directly on my car lift: Then we also got gifted a set of reproduction rubber plugs for the drum brake drums from a good friend and Endo-san handed out NOS spare bulbs in original packing, which will be excellent to put in the glovebox :-) In a local toy-store we found a box full of mini 240Z's for 90 cents a piece, so I got a bunch of them as a gift for customers :-) From one of the Japanese participants of the show, we got gifted these lovely 70ties scanned magazine covers from two Japanese 1971 "Autosport Young" magazines, which assemble to a nice poster when you put them together. Aside from the naked lady, you see all the Nissan Fairlady Z Works race drivers in front of one oft their racing cars. I framed it and hung it in a nice place in the garage: We also got gifted some copies of hand made sketches by Tamura-san, one of the original designers of the S30 car, plus a nice photo from a LHD prototype car: Then I also got this. I understood that this is some kind of rating chart and something very special, somehow linked to Sumo battling, but still have to find out what exactly it means. Another cool thing was this S30.world Japan expedition Lego kit: Which, when you assemble it, turns into an S30 under a Japanese Torii gate with the S30.world logo on it: I was lucky my suitcase didn't burst. I would have loved to buy more stuff, there was definitely no more room for that, and that's fine for my wallet too :-) Expect more updates from our Japan trip soon!2 points

-

Rust at corner of cowl/fender/windshield

Grab a torch - propane will do - and melt the body lead out of that section. That'll give you a better idea of how that sheet metal is shaped and spot welded together. There will be body lead in various places all up and down that pillar. The lead will probably have saved the sheet metal up near the window flange - and may give you a good clean section to weld to at that end.2 points

-

1975 280z Build

2 pointsFYI, I diagnosed a bad EFI relay on a 77 and told the owner to get the relay that @EuroDat said to buy. He got that relay, slapped it in, and the car ran just fine.2 points

-

1975 280z Build

2 pointsNot sure that relay has the same function. It might need some wiring changes to get it to work. The correct bosch relay is 0332 514 120. Bosch have several variants for the VW's2 points

-

Rust at corner of cowl/fender/windshield

I should have something in a donor part if you decide to go that route.2 points

-

What's this part?

2 pointsMy '72 had the same type, it's a York a/c. You have to pull just about all of that off to replace the fuel pump. The smaller round thing above your circle is the fuel pump.2 points

-

Strange early z car electrical issue after being driven.........

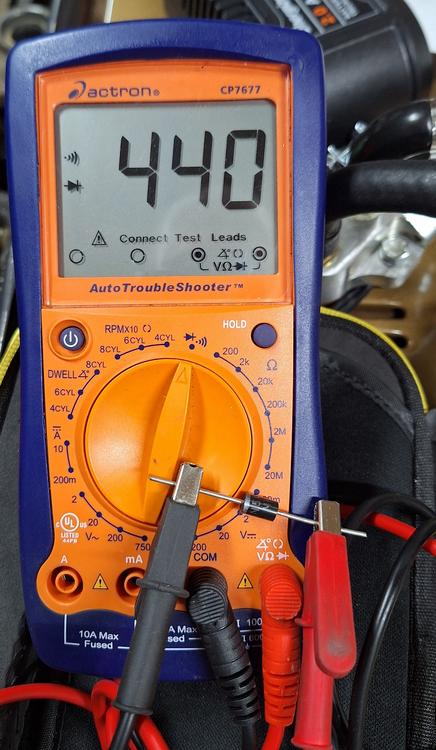

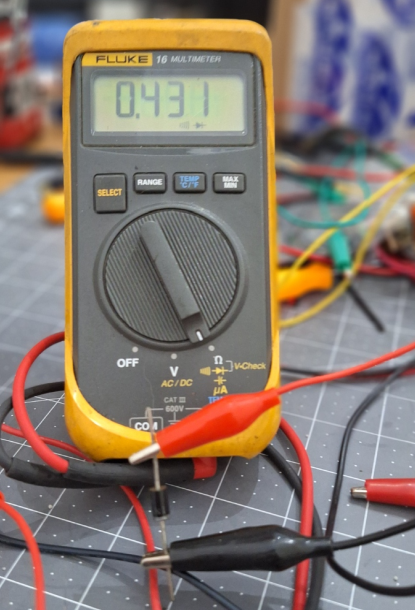

Of course, there is one other possibility. I could have designed the test wrong. I dug out a diode that should be the same spec as the ones used in the plug and tested myself. I found my instructions were lacking. You should re-test with the meter in diode testing mode. You can leave the key in OFF, too. If you test from the ballast resistor to the white/black wire, you should get a result similar to this: With the leads swapped, you should see this: If you do the voltage test, you should see a little less than battery voltage as the diode causes a slight voltage drop.2 points

-

Heater Blower Motor variations

2 pointsNever seen the last type. Suspect it is a retro fit that someone did from some other car. The first one is 240, second is 280, though can’t nail down the change over date. Could be as early as the north american 260 in 74. The fiche might provide the date info2 points

-

Need Help with Hooking Up a Speed Hut Tachometer

(this is for anyone else interested in a little information about some specifics that you raise:) 1. NONE of the above are "Coil - ". (Stock config = Coil "-" is connected to the points output of the distributor. So, new wire from the Coil "-" to your new gauge...(it will be a 2nd wire connection as the Coil "-" needs a "signal to fire" from points or an electronic ignition unit as well - your new gauge is just tapping into that signal)) 2. You don't necessarily need to jumper any of the wires in that connector, but you need to understand the coil wiring to decide whether to JUMP or just ABANDON the G/W and B/W in the connector pictured above. The stock circuit goes like this: IGN SWITCH -> B/W -> Ballast Resistor -> G/W -> Tach connector -> Loop on back of Tach -> Tach connector -> B/W -> Coil "+". The coil gets power at IGN ON through this and the Tach "senses" the flow of electricity to the coil. If you're replacing the stock Tach, the re-route of the B/W back to the Tach is not necessary - the B/W and G/W to that connector can simply be ignored (abandoned). SO - the B/W that goes to the Ballast can be connected to the Coil "+" - either through the Ballast (by removing the G/W and running a short wire from there to the Coil "+") OR bypassing the Ballast and connecting the "ballast's" B/W directly to the Coil "+" instead - IF you no longer need a Ballast Resistor in the circuit. note: I think it's better to abandon and get all that extra wire (and added resistance) OUT of the power circuit to the coil... BTW, the other two wires in that connector: Black - is a Battery Ground. R/L is gauge lighting - it's listed in the wiring schematic as "IL". So Black is the power ground for the Tach - the Tach gets power (battery voltage) from a Green in another connector.2 points

-

Brake fluid leak at master

2 points

-

L20b Cody's Goon

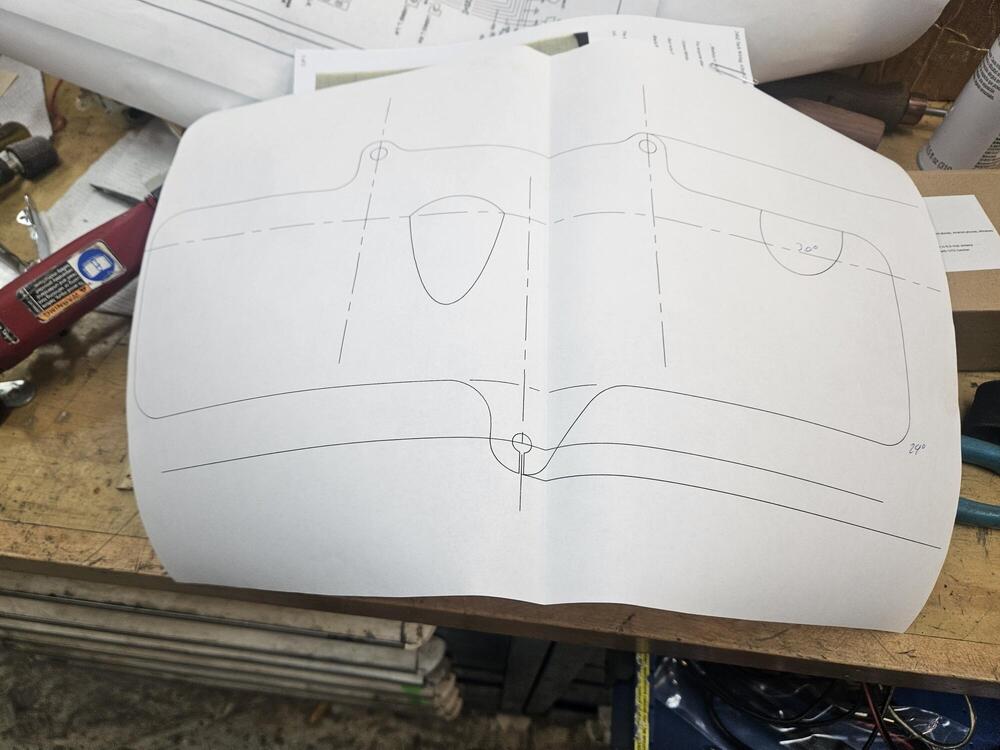

2 pointsI worked on the heat shield/ cable bracket some more today. Here is the current pattern An earlier template on a piece of coil metal I glued it to piece of 16ga I had laying around A little cutting We will have to clearance it around some of the header pipes. Since it's an equal length header, they intrude on the carb area more than some We will use some stainless exhaust tube to deal with the clearanced areas. Once I finalize a design I will have sendcutsend fabricate it for me2 points

-

1971 HLS30-14938 "Lily" build

2 pointsI finished cleaning the cigarette lighter up today Straightened up the bracket and blasted it. Blasted the bottom ceramic with the prongs and polished the chrome rim2 points

-

Z's on BAT and other places collection

Missing dovetail on the passenger door, photo 150. Also the rubber weather strip under the door. They weren’t there in 2019 when it was last on BAT. I just remanufactured the early pre 1973 dovetails for my 1970/71 240Z as they were no longer available. Also did the plastic grease reservoir for the steering rack and the plastic cover for the battery. The Vintage Z cars were restored with parts that were available at the time, 1997/98; not always period correct parts but they did the best they could.2 points

-

Still struggling with car at idle after 8 years

I would still pull that water pump to see if it has the stamped steel impellers . May have some rusted away or broken as found on some. That would solve most of it if bad. Replace with cast iron type pump.1 point

-

Coolant Hoses & Lines

1 point

-

What size bolts will fit?

1 pointGo buy some taps to figure out your issue. Chances are it’s 1.25. You’re going to need to clean the threads regardless. Don’t try to install a bolt without cleaning almost every thread you run into.1 point

-

Z's on BAT and other places collection

The guys with the money, so funny. If they had their way people would have to pay to comment on the cars. The high end BaT car auctions are more like a big money poker game. Who's bluffing who. They don't want to know until the sale is over. https://bringatrailer.com/listing/1971-datsun-240z-345/1 point

-

SN 00042 Restoration; The Older Twin

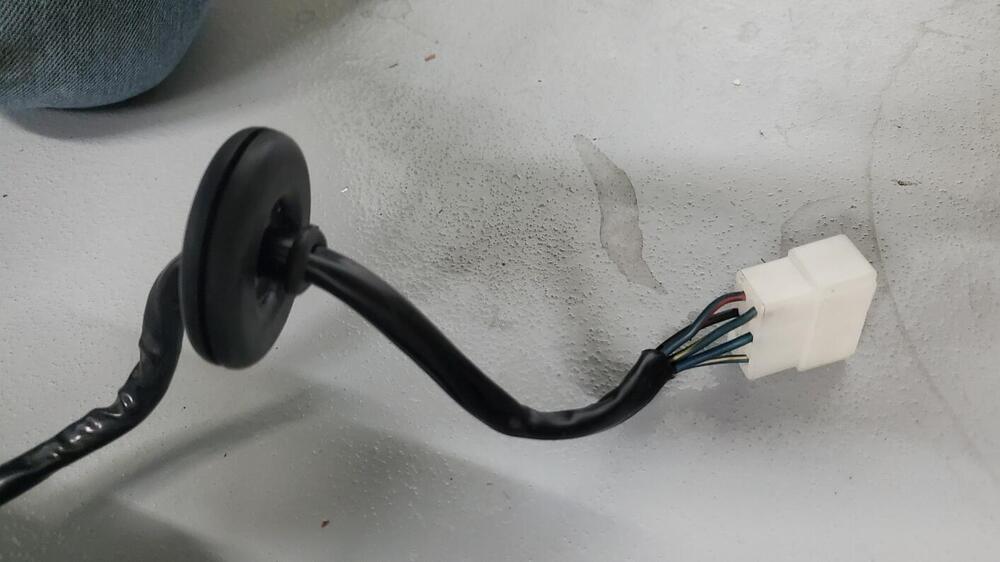

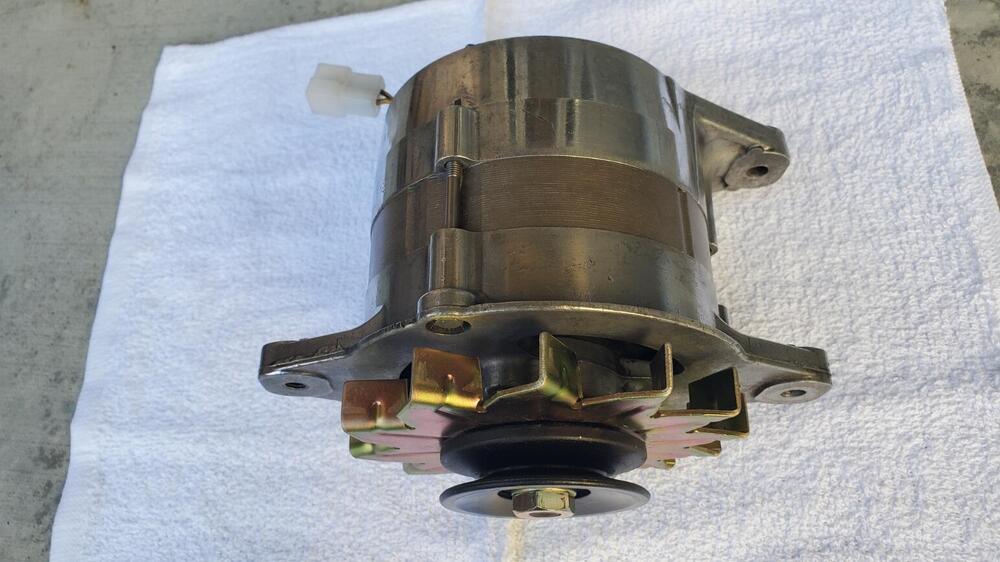

Body work is continuing on the car but at a slower pace than I was hoping. I wanted to get the body back from the shop before Christmas, but I now think it will not arrive until early next year. I will go to the body shop next week and see if I can get a good date on when the car body and paint is expected to be completed. I last went to the shop just before Thankgiving and Carlos was working on getting the door gaps aligned and correct. Still needs some work as the door gap is a bit wide on the drivers side while the passenger side has a mild taper. Latest body shop pictures of the doors is shown below. I looked into getting a local shop that did dash repair work to do the crack repair, but it didn't sound like they could produce what I wanted. Their price was around $400 and they mentioned that 'there would be some scarring left'. I didn't feel comfortable with that and the cost was a bit more than I wanted to pay, so I read up on the dash repair thread here and decided to do it myself. I am actually pretty happy with the final results. It is not perfect, but quite good even under my bright LED shop lighting. In natural light the dash looks perfect. I will try and sequence the process in the pictures below. I used the 'silly putty' technique to match the grain. There were also a couple of small hairline cracks, so I used the plastic epoxy to fill those while I was at it. I am cleaning up other parts as I continue to wait for the body. Below are some of the re-furb pics of the Windshield wiper motor, alternator, brake booster, steering rack and choke knob. All connector housings and most terminals were replaced where needed. FYI: I purchased the steering rack boots from 'Best Parts On-Line' for about $45 including shipping. These are the same ones that zcardepot sells for over $120. Very happy with the fit and feel. On the valve cover, the car arrived with the incorrect bolts that secure the spark plug wire supports. So I replicated the correct style bolts by filing off the top numbers on similar bolts and polishing the head. Thin clear coat on top to prevent rust. Cleaned up the distributor and installed the fuel pump. Not sure about the correct color of the distributor cap, but this green-gray cap was sitting in one of my boxes so I decided to use it. The distributor cap that was installed when car arrived had a cracked tab, so needed replacing. Also, input regarding the correctness of items is appreciated (though not always agreed upon). Items like the correct bolts for the valve cover plug wire supports were pointed out via PM and the item corrected. Thanks!1 point

-

Still struggling with car at idle after 8 years

1 point

- Still struggling with car at idle after 8 years

Thats not vapor lock. Different issue entirely Depends how high it climbs on whether its an issue or not. Lots of things can contribute to not being able to shed heat.1 point- Datsun Tools

1 point- 1975 280z Build

1 pointIt wasn't meant to be a link, just an abbreviation. Something in the browser or forum software does that automatically, I think. ithink.com link.com thislinkwontwork.com1 point- 1975 280z Build

1 pointThis (F 026 T00 064) was the one I ordered, I got impulsive and this was the first part number I came across from this post here from @SteveJ . I couldnt find any other posts on here with the other part number at the time. The 0 332 514 121 relay has extra pins, this is because the extra pins are for the california vehicles, at least according to Jbugs. I suspect that using that relay is just fine since the car doesnt need those pins. This is the description for bosch relay 0332 514 121 accordinng to Jbugs BTW @Zed Head That CZCC link doesnt work1 point- 1975 280z Build

1 pointEFI/pump relay. Which one did you order? You didn't say. Don't overlook that the pump relay is controlled by the switch in the AFM. And that there is no "prime" like on today's vehicles. The pump relay is energized by the AFM switch or when the key is at Start.1 point- Z's on BAT and other places collection

Lots of effort, time and money invested to create a 1971 Corvette LS6 convertible tribute clad in Japanese sheet metal and copious amounts of fiberglass . To each their own.1 point- Headlight upgrades

1 pointI've looked at LED headlights off and on over the past few years. But honestly I don't really see a need for it. LED's are great for saving power in a house, boat, or RV. However, for a car that is NOT designed to run LED headlights, you really need to do it right. And, this won't be a $100 option. I've seen cars running around with cheap LED's and the flicker / light output is too annoying for my blood. A proper LED setup will need new drivers (circuit boards), relays, quality bulbs, and some nice wiring. The right setup also won't require cutting your existing harness and it will provide quality output. When I dug further into this venture, I found the Marimoto setup looks like a good one. But you're talking about $400-$600 for the bulbs plus another hundred or so for the wiring. Something to ponder anyway... FWIW1 point- Strange early z car electrical issue after being driven.........

Steve won’t get notified on the forum if you don’t use the “@“ before the user name. In this case it’s “@SteveJ”. Just a heads up when you are replying to a certain member with a message or response.1 point- Strange early z car electrical issue after being driven.........

Okay, I'm going to assume the battery is disconnected. Put the key in ON. Put your meter on resistance. If there is more than one setting, put it on the lowest setting. Put the positive lead on the black/white wire at the ballast resistor. Put the negative lead on the white/black wire at the T connector. (Yes, you'll probably need some help. Record the reading and report back. Swap the leads and remeasure. Record the reading and report back.1 point- Strange early z car electrical issue after being driven.........

Good opportunity to learn how to use a multimeter. Check voltage at idle and while raising RPM. Some of the conversion plugs from MSA have been known to melt and fail. You can get a cheap meter for cheap at a place like Harbor Freight. https://www.harborfreight.com/7-Function-Digital-Multimeter-59434.html1 point- 4-Bolt axle frange bolts.

1 pointThe Kiwi girlfriend has lived with me for the last 10 years. She's great I'm lucky1 point- 4-Bolt axle frange bolts.

1 pointOK so my girlfriend who has a New Zealand accent can get 50%. :) On another note, it's starting to look like there's a scammer in the community. bww 5325 who's only posted twice and joined November 15th Told me about Suly38B@gmail.com who claimed to have a gas tank and long story shorter I sent him $300 December 1st and he's gone radio silent on me.1 point- Z's on BAT and other places collection

While it looks nice and will make a good starting point why was the color changed to a non Datsun Z car color? The late Paul Taylor's 240 has emerged from the shadows and is for sale @ Carolina Muscle Cars for 125K.1 point- Just Another Damned Z Car Project Thread

I have a picture of a girl called Flower and it's NOT because of her sweet smell. The complete opposite actually. Happy birthday!1 point - Still struggling with car at idle after 8 years

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.