Hi Guys:

I've seen quite a few of these in new cars. When the Dealerships received the cars, the hubcaps, carpet, tool kit, outside rear view mirror, inside rear view mirror, booklets etc were in the rear deck area.

Nissan had an extensive "Pre-Delivery Inspection" process during which the car was mechanically and physically checked over. In addition to preparing it for delivery to the Customer - or actually to be turned over from the Service Dept. to the Sales Dept. {then the Sales Dept sold and delivered the car}

The Owners Manuals and Warranty Booklets along with other Paperwork such as the MSO went to the Title Clerk {of Office Manager} in the Dealerships. They in turn processed the MSO for State Title, filled out the Factory Warranty info to be sent to Nissan USA, and stamped the owners warranty info on the warranty cards. If they were really on top of things - they also recorded the VIN, Engine Serial Number and Key Codes for the new owner in the Warranty Booklet.. but sometimes that didn't get done before the customer that had been waiting for his/her Z wanted to take it...

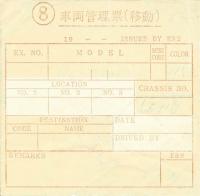

During PDI - all extraneous "trash"... boxes from the hub caps, the paper they were wrapped in, the vinyl sheets covering the door panels, wrappers from the seatbelts - - - and yes - - -these funny little inspection notes written in Japanese - and considered of no value - - went into the trash.

The mechanics had to fill out a PDI Report - and one copy of that was supposed to go to the Customer, while other copies went to Nissan. Nissan paid the dealers for PDI services...

I still have the Inspection sheet that came in my Blue 72 Z - but only because I took the car right off the truck - and did everything to it myself.

Who would have ever thought back then that anyone would want to see any of that junk - - 98% of the Datsun 240Z's left their hub caps and stock wheels at the Dealership, and the Customers never saw them. For years we had large stacks of both stock wheels and hubcaps sitting around - and after a time we just threw most of them in the dumpster. There just wasn't enough room to keep them all. If you bought your Snow Tires from the Dealer instead of a Tire Shop - we'd throw in a set of stock wheels to mount them on ;-) The Parts Dept sold a few over the counter for customers that wanted them for snow tires as well - - usually $5.00 each, $10.00 if you wanted both stock wheels and hub caps. For years and years and years no one wanted "D" hubcaps, they were ugly, and stock 72/73 hub caps were just passable... Moon Dishes were the only way to go if you didn't have "MAG's"..

On the Inspection sheet - after all these years one can just barely read what is left of the ink from the "carbon copy"... it wasn't too bright to begin with.

FWIW,

Carl B.