This will be a discovery trip for all of us. I'll keep the thread populated as best I can.

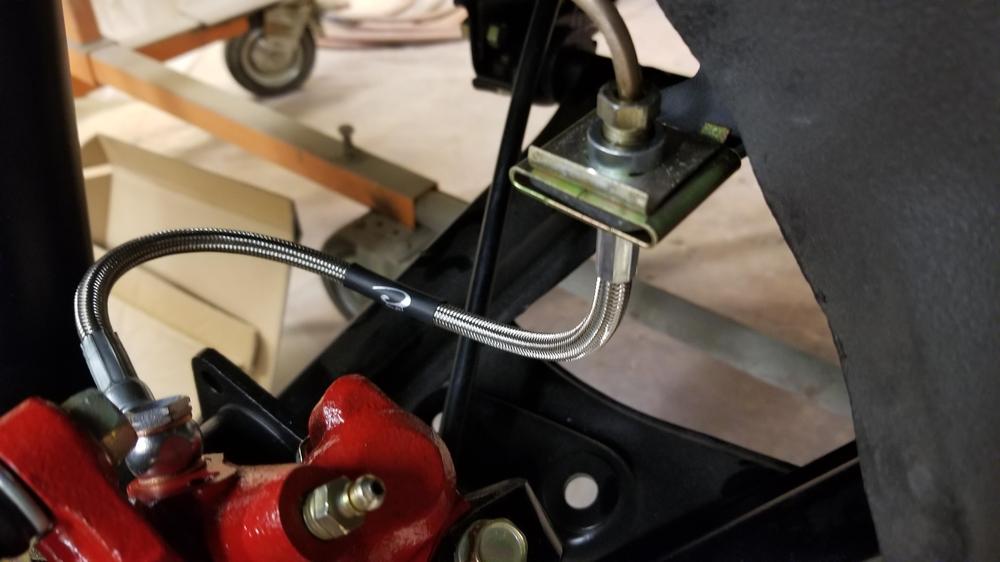

EFI fuel supply is the next topic. Many options are available, but there are two main competitors.

1. External swirl pot with internal EFI pressure pump, fed by exisiting low pressure carb pump. Two pumps, lots of connections, extra can to mount and hide, not ideal. Something like this. http://www.burtonpower.com/efi-fuel-pump-and-swirl-pot-assembly-wfp600.html

2. Install an Internal hi pressure EFI pump. Quiet, cool running, just one pump, but need to add some baffling or swirl pot and of course cut up a good tank. Definitely the cheapest solution but requires the tank be modified. Have lots of tanks to hack up. Will also install modern fuel level sender at the same time. TanksInc.com has a good option. http://www.tanksinc.com/index.cfm/page/ptype=product/product_id=84/mode=prod/prd84.htm

Holley just came out with a fuel tank "mat' (HydraMat) that covers the bottom of the tank and soaks up fuel like a sponge. Any fuel in the tank is soaked up and available to the pump. The ultimate in anti-slosh, anti-starvation device. Not cheap, but an excellent solution for putting efi pumps in non-or minimally baffled tanks. https://www.holley.com/products/fuel_systems/hydramat/hydramats/

Subscriber

Subscriber 5Points3,770Posts

5Points3,770Posts Subscriber

Subscriber 3Points11,142Posts

3Points11,142Posts