I attempted to remove the valve spring retainers from my exhaust valves this weekend with the homemade valve spring compressor tool I have use successfully before. However, this time, it didn't work as well as I recall it did last time. After futzing with it for a couple of hours and only getting one retainer off, I gave up and ordered one from Zcardepot.com. My homemade one interferes with the came towers and extracting the collets out is a real pain. Hopefully the new one will be a lot easier to use.

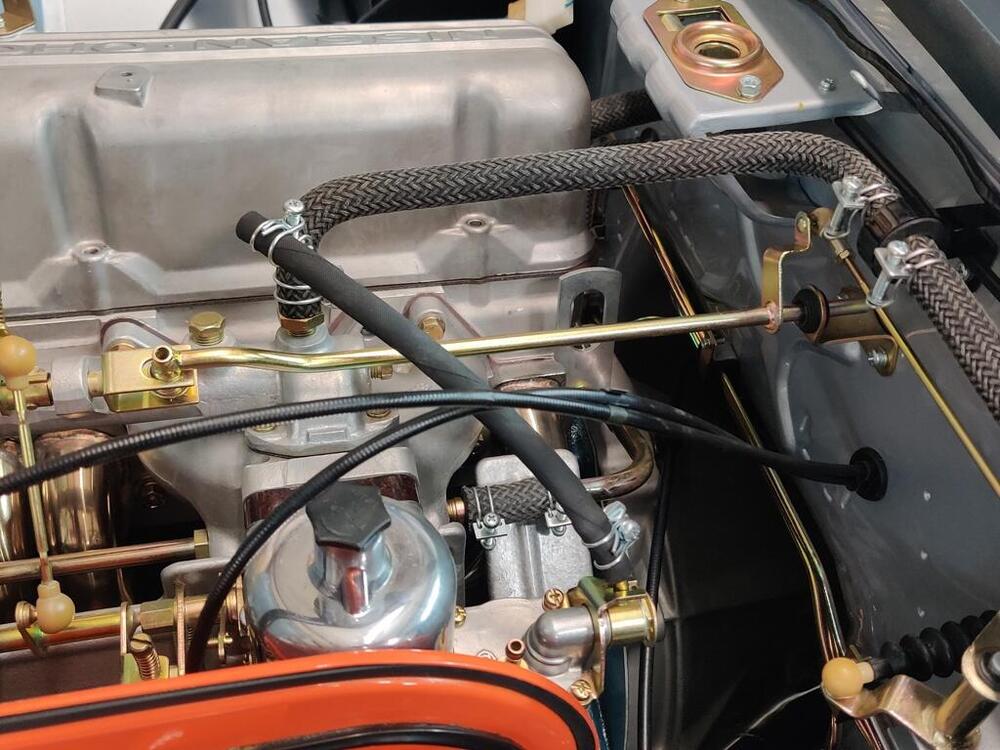

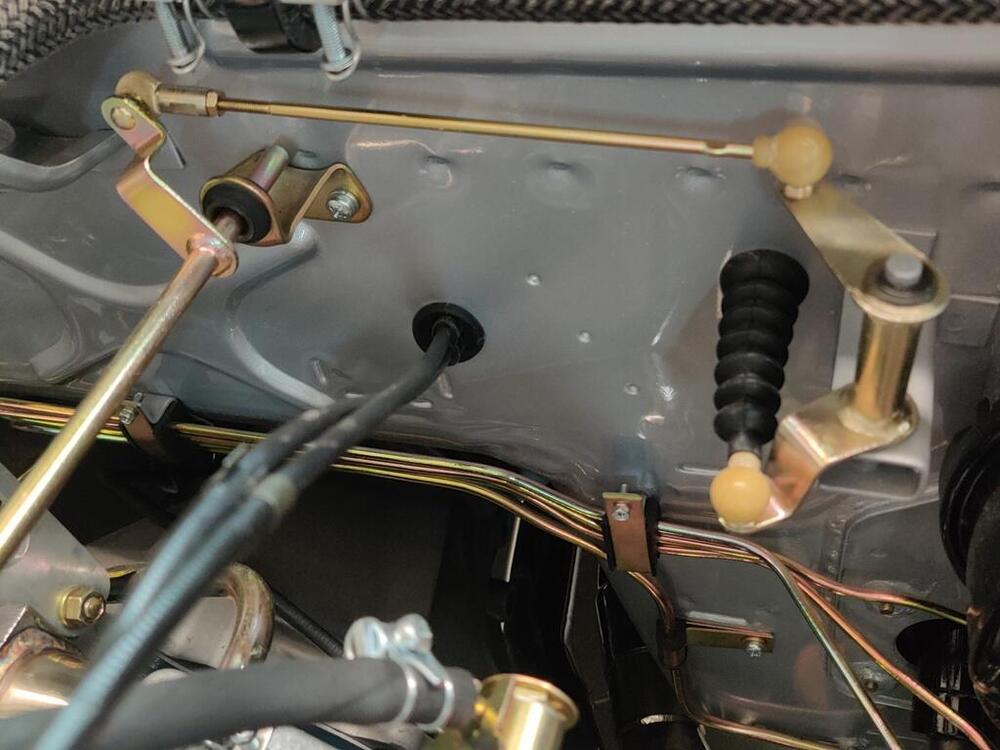

In the meantime, I am working on what there is left. One of those things was installing and adjusting the throttle linkage arms. While I am familiar with this part (see red arrow), I never knew what its purpose was - do you know?

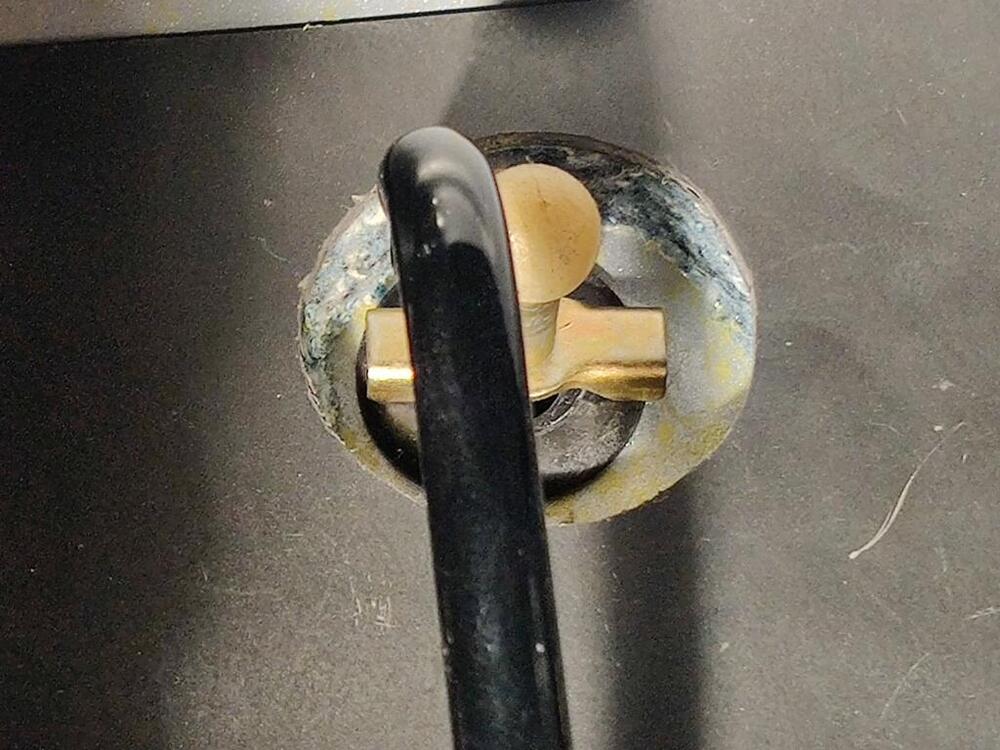

Well, I may have figured it out. I think it is a linkage "stop". As I was assembling the linkage, it seemed logical to me that the little wings on this part may have been intended to contact the back of the rubber bellows that attached to the firewall. As I worked to set the lengths of the rod (this short one and a longer one have one threaded ball socket end) the location of this piece fell naturally to a position that eliminated all of the "slop" in the linkage after the throttle plates in the carburetors had just contacted their screw stops. In other words, you can then set the depth of this "winged" piece to contact the back surface of the bellows just at the point where the throttle plates in the carburetors have closed. Doing this, you will prevent introducing slop in the linkage which occurs after the throttle plates are shut but you continue to release the gas pedal as far as the pedal return spring will pull it from the floor.

After setting the winged piece, I confirmed that even the slightest movement at the pedal caused carburetor shaft (and thus, throttle plate) movement. When releasing the gas pedal I now have a muted "thud" as this piece hits the back of the rubber bellows... and allows no more movement in the linkage beyond the throttle plates in the carburetors' seating.

Kind of cool! It will be interesting to see how that all feels when driving the car. While I was doing all this, I ensured that I got full throttle opening at (both) carburetors by pressing only on the gas pedal inside the car. I am never all that surprised when I check and find that pressing the pedal to the floor does not fully open the throttle at the engine!

The plastic ball sockets on the linkage turned white during the plating process. To address, I used a propane torch and very carefully heated them. The heat causes some type of reaction which restores the color of the ball socket. But, you have to get it hot enough that melting starts to occur. After heating, I went over them with some fine grits of sand paper to restore areas that has melted a tad.

White socket... and my throttle linkage stopper in action (though I think I need to flip it around 180 degrees):

Throttle linkage detail:

I have read about getting dinged at Zcon for valve covers which have been glass bead blasted. I also know that there is quite a bit of variance in finish with glass bead blasting. You can use different media, different pressures, and even do vapor blasting which uses media along with water. For my valve cover, I tried cleaning it really well with #0000 steel wool and degreaser. And then I tried some Aluminum Brightener. After those efforts, I still had darkish areas that looked like stains on my valve cover:

So, I started experimenting with glass beads set at very low pressure. The glass beads I was using have seen may work cycles and I was using only 20 psi. However, I was getting pretty good results. In this first pic for example, I concentrated efforts on the area at the top of the valve cover between the oil cap hole and the casting bump (for the spark plug wire holder). In the second picture I was concentrating in the area between the two bolts. In the third picture you can see the area of transition (darker, not blasted area on the right).

In this first picture below, I had hit the N and and the I in Nissan and some of the area above and below the N. The downside is that it takes a lot of time at 20 psi. But, it did make a big difference in lightening the valve cover. I got a little more aggressive in a few areas with 25 psi, but I think that started to look unnatural. Anyway, I was pleased with the overall result. A note, if you do this, you have to seal the vapor compartment in the valve cover, or remove that plate inside the valve cover like I did so that you don't leave glass beads in there.