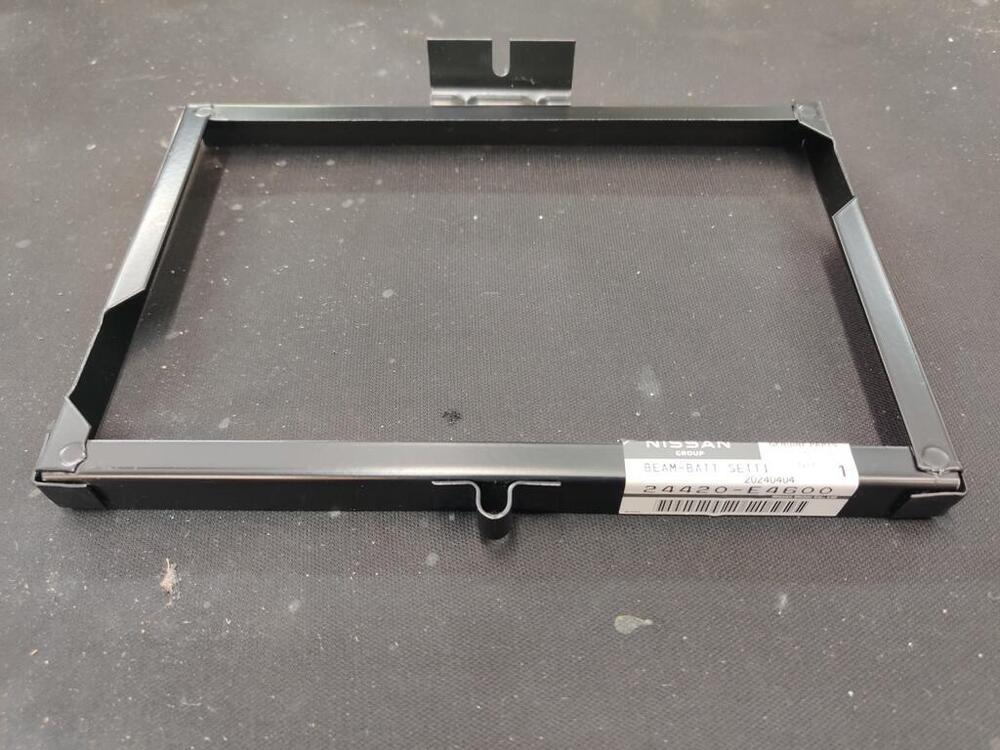

Lately, everything I attempt to do on this car fights back. For example, I have sourced a new battery, battery tray, and battery frame from a Nissan dealer. So, with all these "factory original" parts, how do I end up in this situation?

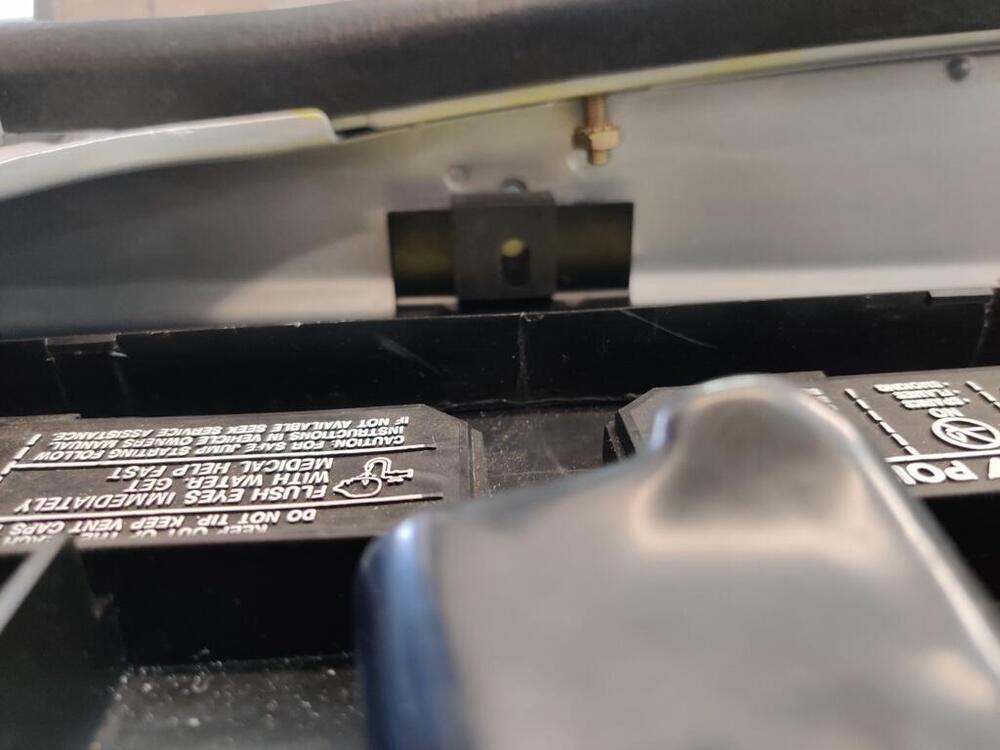

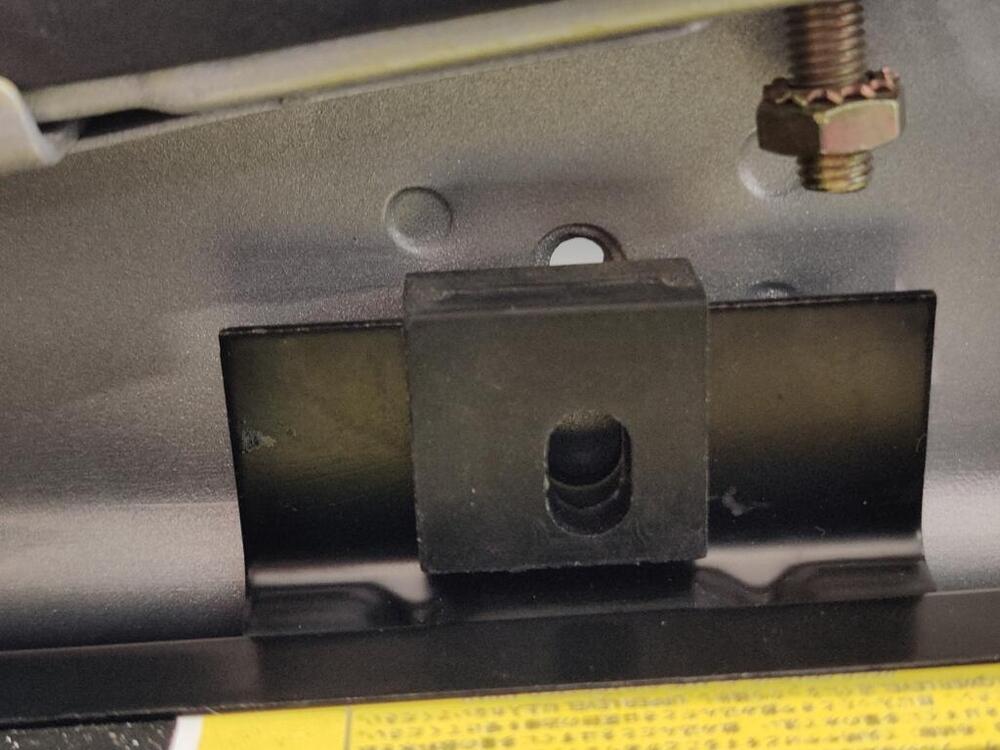

A closer look:

Is this battery shorter than the original? Is the battery tray thinner/shorter than the original? A combination? When I saw this, I just laughed and walked away to do something else. I am also wondering why the slot in the rubber part here is offset to one side. I have no clue.

Next came more work on the right side door. I am still dealing with the consequences of the paint shop removing the doors (and I specifically said not to). Getting the right side door aligned exactly the way it was is a pain in the arse. Tightening the hinge locating bolts, loosening... rinse, repeat. I had them where they belong and did final body work finishing across the door gaps. I had it really close to perfect. Now, I am struggling.

The door is made of thin metal. It is quite possible that by the time you bolt in the stainless steel window frame and put in the regulator and the glass, the shape of the door changes a bit. Probably a key piece of helpful info for those of you reading this and yet to apply paint to your car in the future.

After quite a bit of fiddling, I got the "feel" of rolling the window up and down right - consistent slight amount of force throughout the travel both downwards and upwards. Next, I made a vapor barrier for the door and put that in place (sorry, no pics - I will remember when I do the left side).

I had to straighten the lock pull rods as they were a bit "bent".

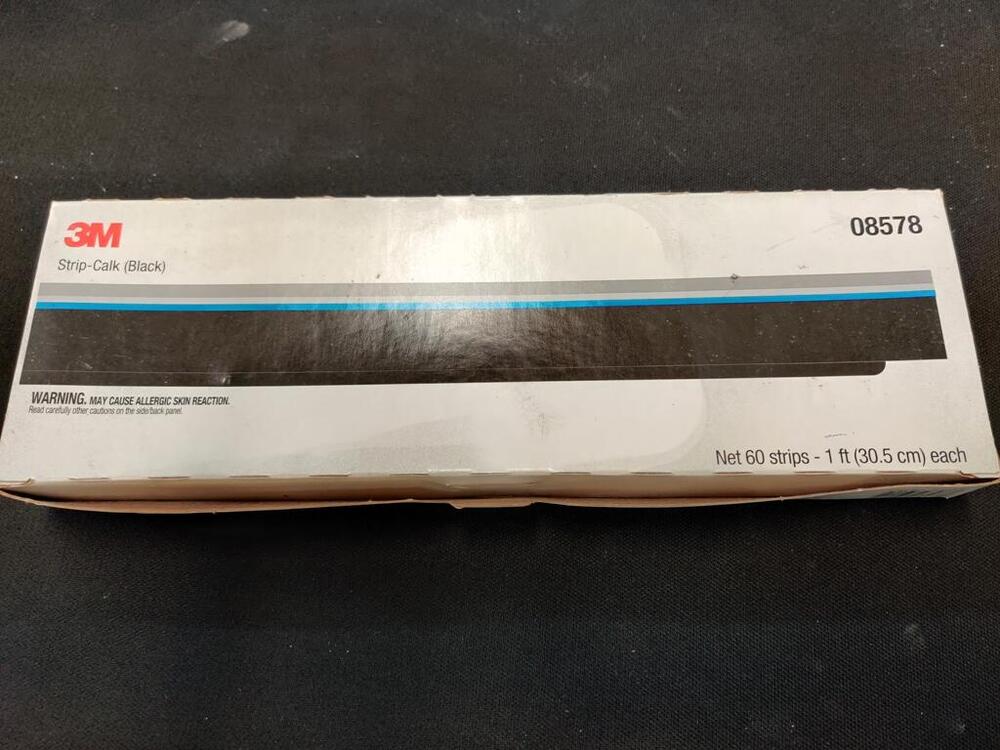

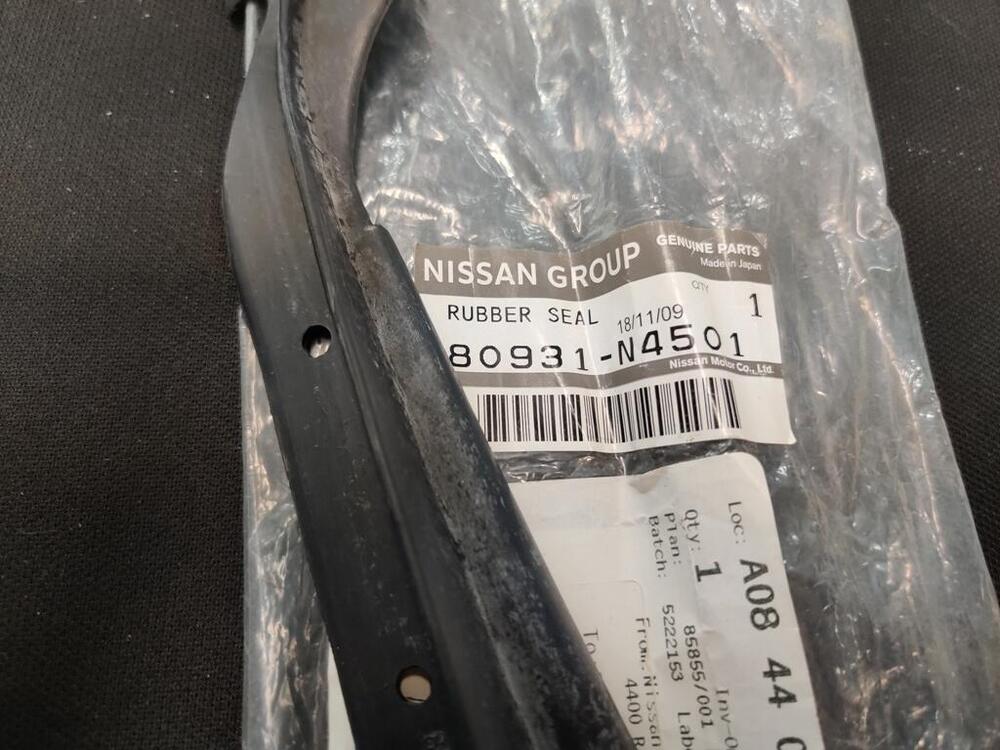

The product I used to attach the vapor barrier to the door (first pic of three), and new door frame seals:

For the front door frame seal, I couldn't get my favorite contact adhesive to stick to it properly until the third try. After the first two, I scuff sanded it. Only then did the adhesive stick to it properly. I have some adhesive clean up to do still. After these seals were glued into place, I could put the inner door panel on.

I sourced reproduction door panels some time ago, probably a couple of years. They appear to be good quality, but I decided to move the door panels from my track car to this car. I purchased these new from a Nissan dealer around 1994. They are still in very good condition. The track car will get the repro panels.

Getting the pull strap on took a crazy amount of time and effort. The chrome pieces do not want to snap into place. I had to massage and modify a bit here and there until they would finally latch into place.

Anyway, that is how it can go sometimes. Much more difficult than it should be. But, I press onwards. 😉

Subscriber

Subscriber 5Points1,282Posts

5Points1,282Posts