Okay. Time for an update. I’ve done a bunch of random stuff, mostly on the dash wiring, but here and there with other stuff…

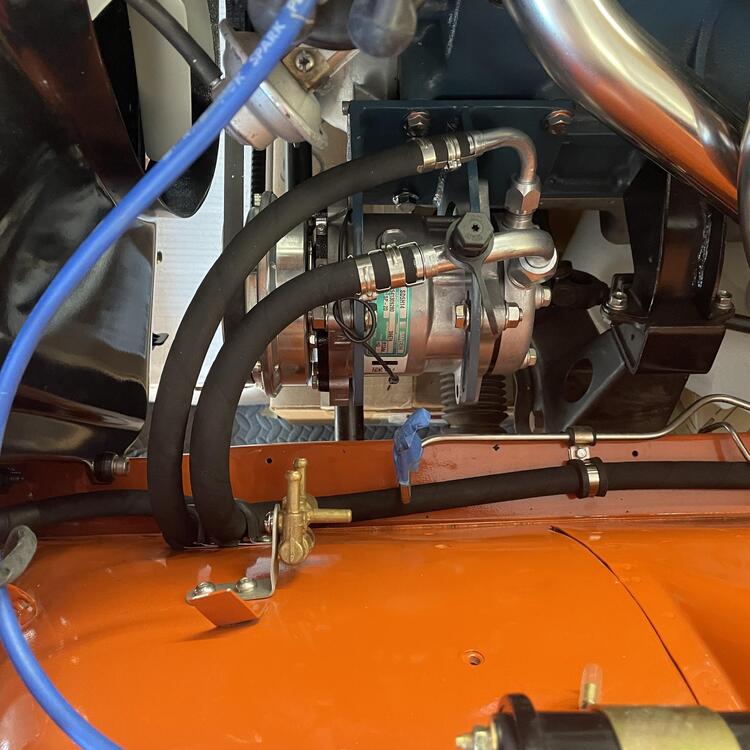

First, I e been working on the AC lines. I went around and around in this one, looking into making stainless line, then buying the Godzilla kit, and then buying Vintage Air hard lines. I ended up settling on a mix of hardlines and Aeroquip E-Z Clip hoses.

”Prototypes (i.e. failed attempts):

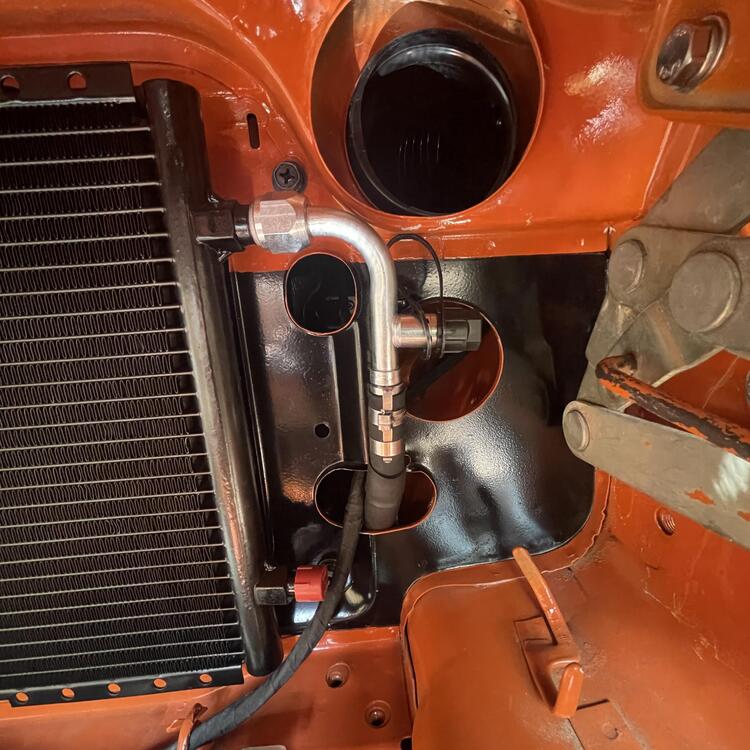

AC hard lines for inside the cabin are in, but ugly. This one was a pain. I went through several pieces until I got the lengths and bends right, and even these aren’t wonderful, so I’ll redo them one more time.

I opted for Vintage Air U-Bend-Em aluminum hard lines because stainless was going to be far too expensive and the hose options I investigated didn’t quite cut it. These fit okay, but you can see the -06 line is too long and I had to cram it in. I got another so I could make them fit better. It’s important because right now they are pulling on the lines they connect to in the engine bay.

The firewall insulator is OEM from eBay. It’s in pretty good shape considering its age.

• • •

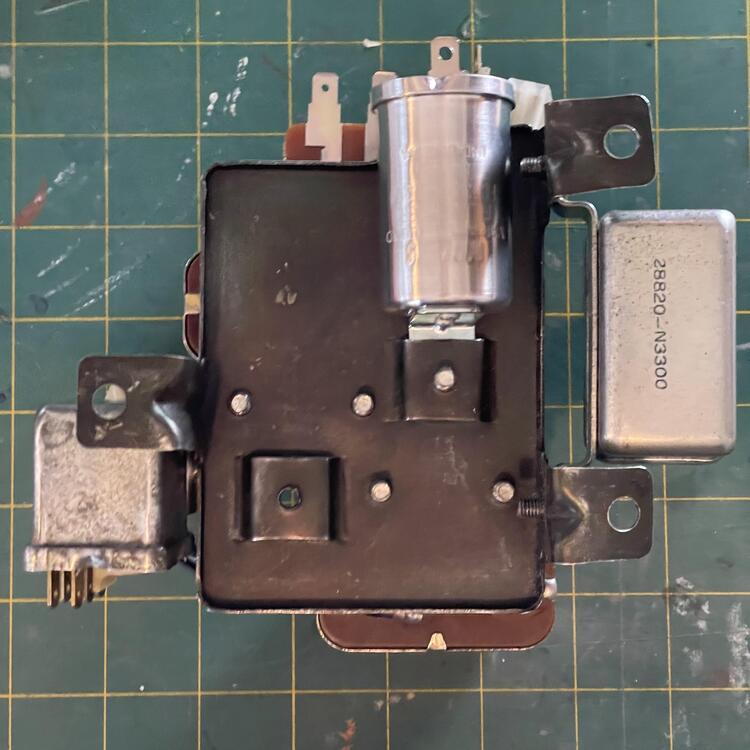

I’ve also been scrounging up my relays, which I talk about in my wiring thread.

The fun one to find was the seatbelt warning buzzer and the three wire door switch, but I was able to find them after a lot of direct messaging.

I’m not 100% certain all of these relays are good (still testing), but I cleaned up the best looking pieces from my pile and assembled them a few weeks ago.

• • •

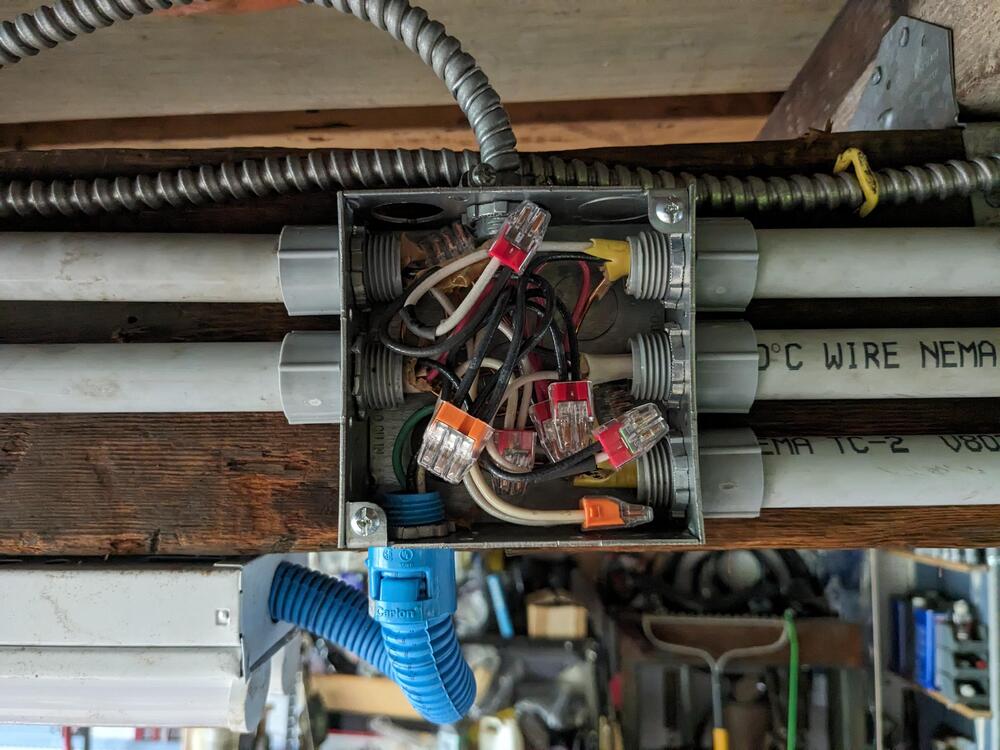

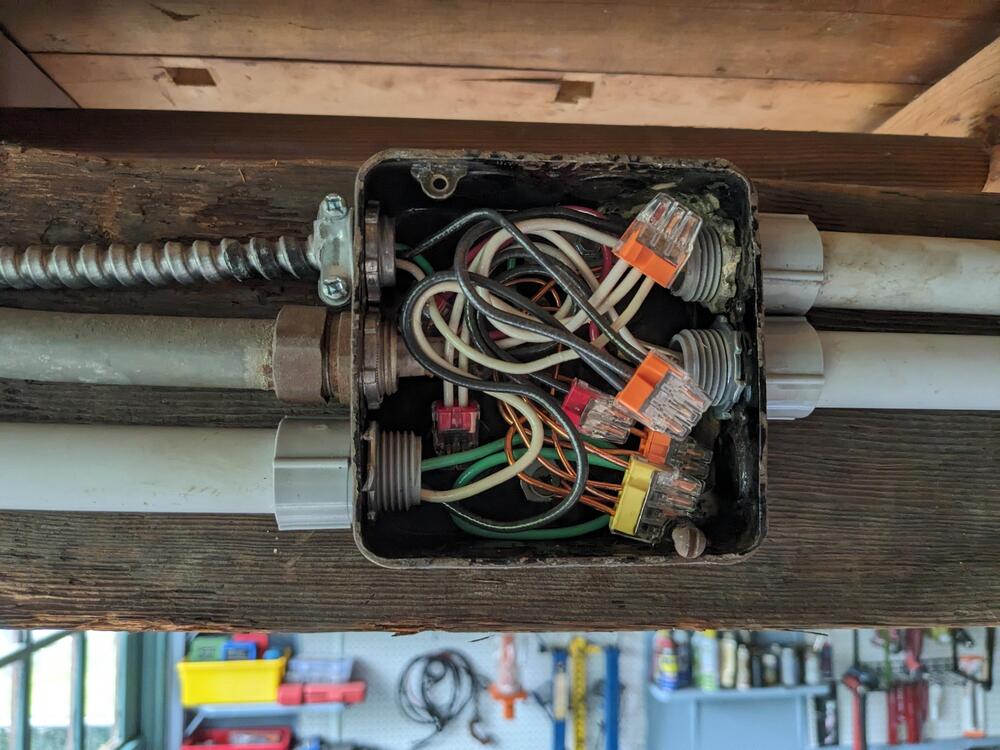

The wires for the dash harnesses are all cut, spliced, and zip tied, so the next step is test fitting them in the dashboard and marking where they will get cut for the terminals. I won’t be wrapping these until I know everything works, so that’s a ways off.

They look like a mess here, but they’re simpler than they could have been. They’re pretty heavily modified, with the stereo and antenna deleted and add provisions for various new components like footwell lights and USB-C plugs. All of the splicing and positioning has been checked and verified against the diagram I made as well as the original harnesses. The wire is heavier gauge and marine insulation (yes, overkill). Will it fit? We will find out.

Why? Burnt wires, the PO used a harness for an automatic in a manual car, I wanted to incorporate the fuel harnesses into the dash harness, and to make it fresh.

That right there is over a year in the making. Glad it’s over.

• • •

Now on to the engine bay.

Carb-side AC lines are done! The hose for the other side is in the mail, so I’ll knock that out soon.

You can see the prototype of the hard line in the photo above. There are two problems with it: the max length is 72 inches, which is about two inches too short to get a nice clean routing, and about six inches too short to tuck it away and make it discreet; and the end is just slightly wrong for the R32 Skyline AC drier/receiver in the last photo in this sequence.

I like that drier too much to switch it out and I’m uneasy about modifying the end of the line and potentially not getting a tight seal, so hoses it is!

The hose for the E-Z Clip system bends tighter than regular AC hose, but it doesn’t bend quite as tightly as I had hoped (it’s rated at a 2” radius for the -08 hose) so it gets weird in a couple of places, and I’m still unsure if these Danfoss E-Z Clip fittings are going to be air tight. We will find out when I try to charge the system.

You can barely make out where I sleeved the hose at points where it might rub on something. I used three layers of heavy duty shrink wrap for this and I think it looks almost like it’s supposed to be there. All I need to do with these, though, is add a hose separator that is the right size to keep that -08 hose from flexing too much. I have two of them in the mail to me now.

• • •

I installed the fuel rail for the triples the other day. This was surprisingly involved. I thought I would just slap it on and call it done, but there were several barriers; nothing crazy, but time consuming and requiring thinking it through.

I had intended to use the empty M10x1.0 holes that are next to the M8 manifold mounting holes, but the rail brackets aren’t drilled for that, and the manifold nuts are too close. I tried a bunch of different workarounds but in the end it was easier to use the manifold studs as the mounting points.

To do that I had to use longer studs, which meant grinding some relief into the manifold. I REALLY didn’t want to do that, but I caved and broke out the Dremel tool.

Was I paranoid I was going to pierce the runners? 100%

But I didn’t. I switched to hand files after a while just to make sure I wasn’t going through it too fast. All those years of model making have paid off in writes on this car.

So once that was done I put the thing together and realized these rails are meant to go with electric fuel pumps. I have a NOS mechanical pump on this car and I worked too damned hard to find it to go dumping it for this, so the rail got a trim and beads rolled on the end. Looks like it’s supposed to be like that now.

After that I just had to tweak the bends to make sure it cleared everything and it’s good to go. Now to figure out the fuel hoses and find a fuel filter bracket.

• • •

So the big question now is…

HOW TO ROUTE THE FUEL LINES?

I would like to use the return line, so I would need to send the fuel back to the other side somehow. Right now I am leaning toward installing my Mikuni cooling bodies and running a line across the front of the engine under the coolant line, but I’m trying to think of something more elegant.