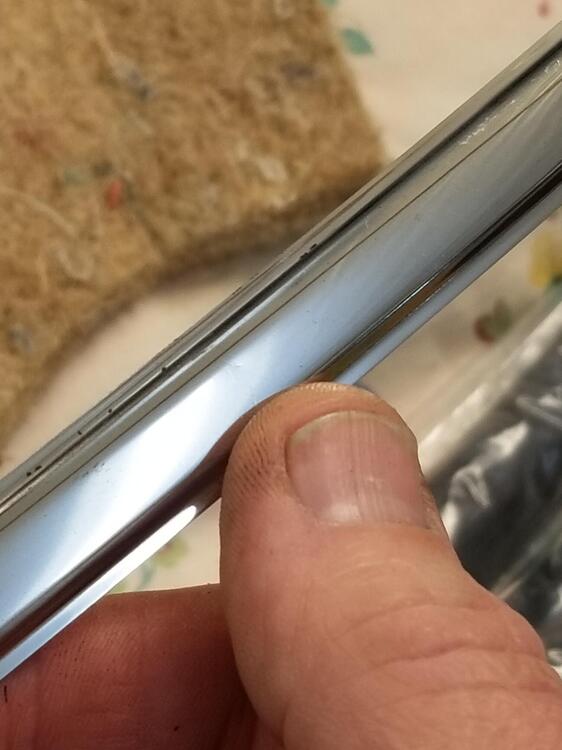

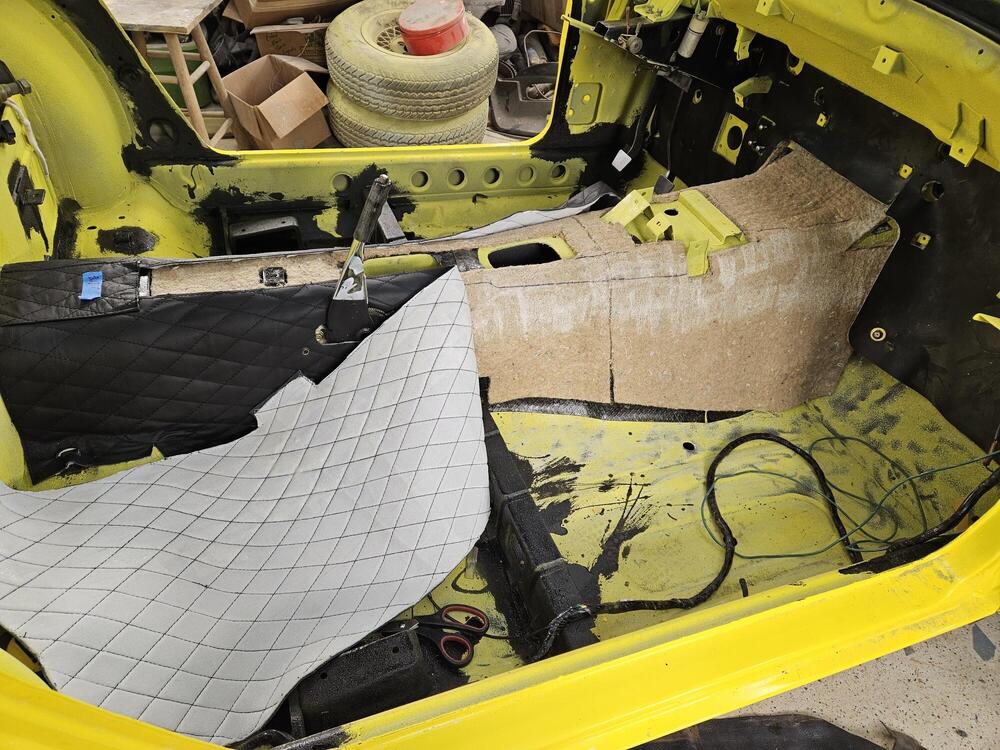

Today, I got the right side window regulator in and was successful in getting easy, and smooth operation of the widow. I also messed with the door hinges a bit to improve upon the door alignment. I still can't believe they removed the doors - I had the alignment nearly perfect!

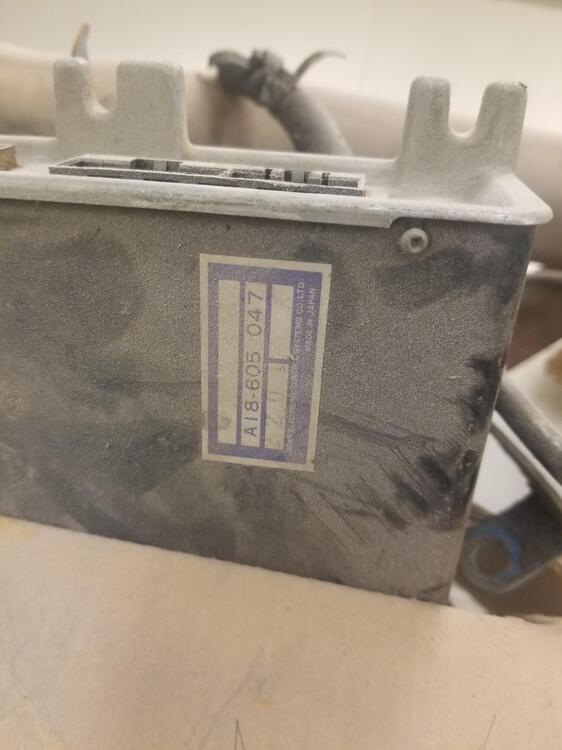

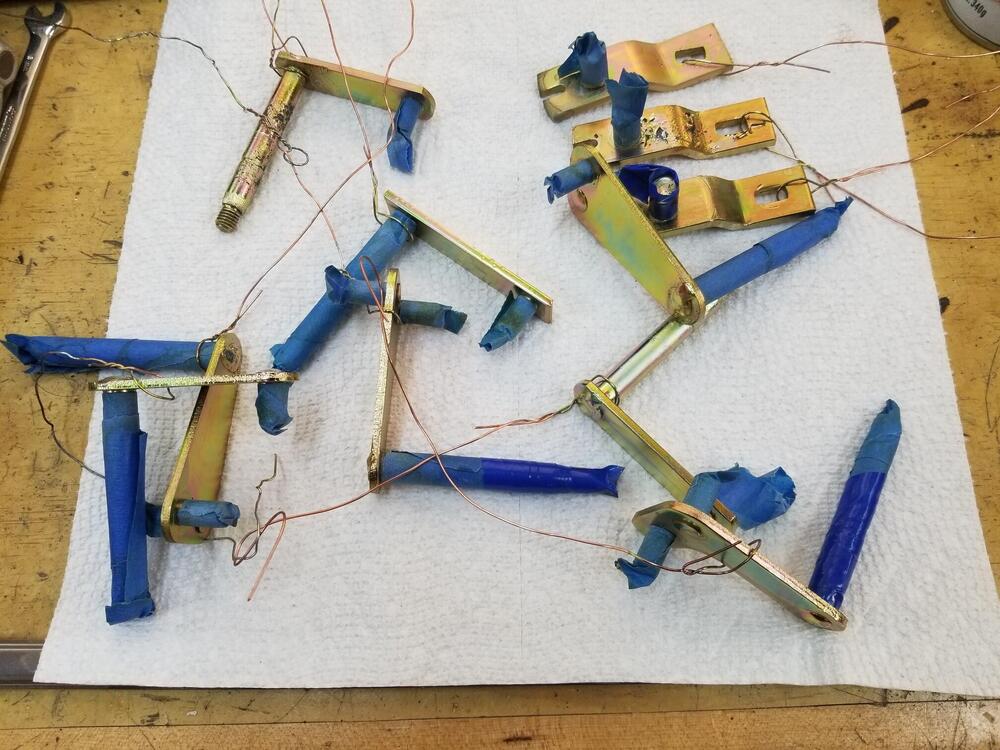

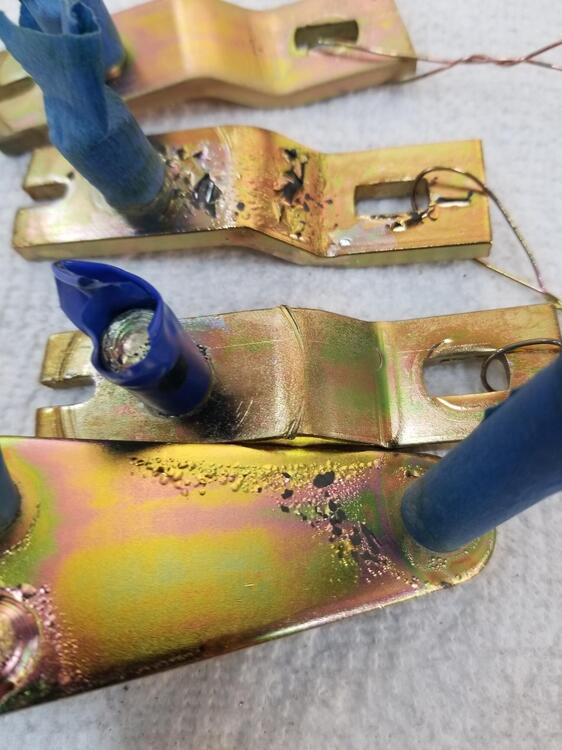

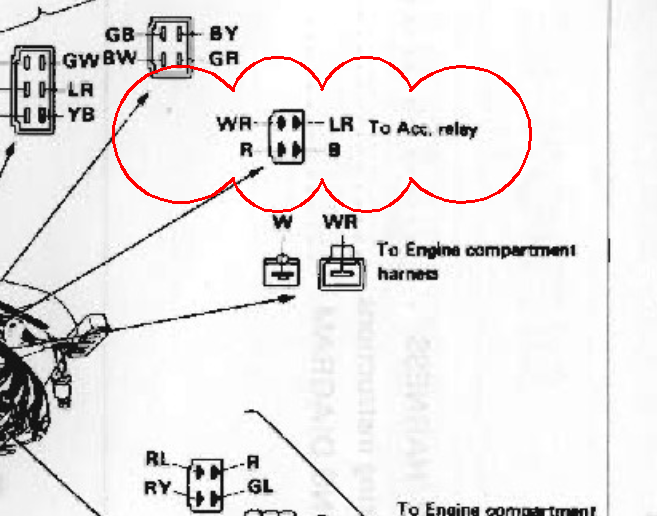

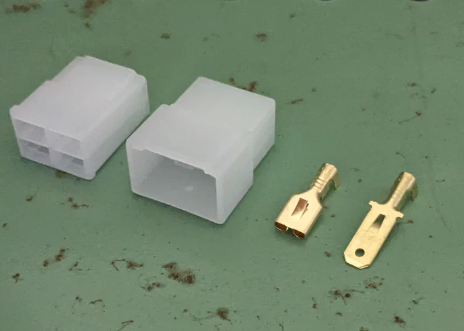

And, I assembled the other of the new headlight harnesses (it is a PITA to pull the wires through the new sleeves if you don't remove the electrical connectors from the wires, which I did not). I also replaced the plastic/nylon headlight screw receivers. When I had the buckets plated, I did not know that replacements existed. So, I had them plated with the receivers in place. They didn't "do well" with the plating process.

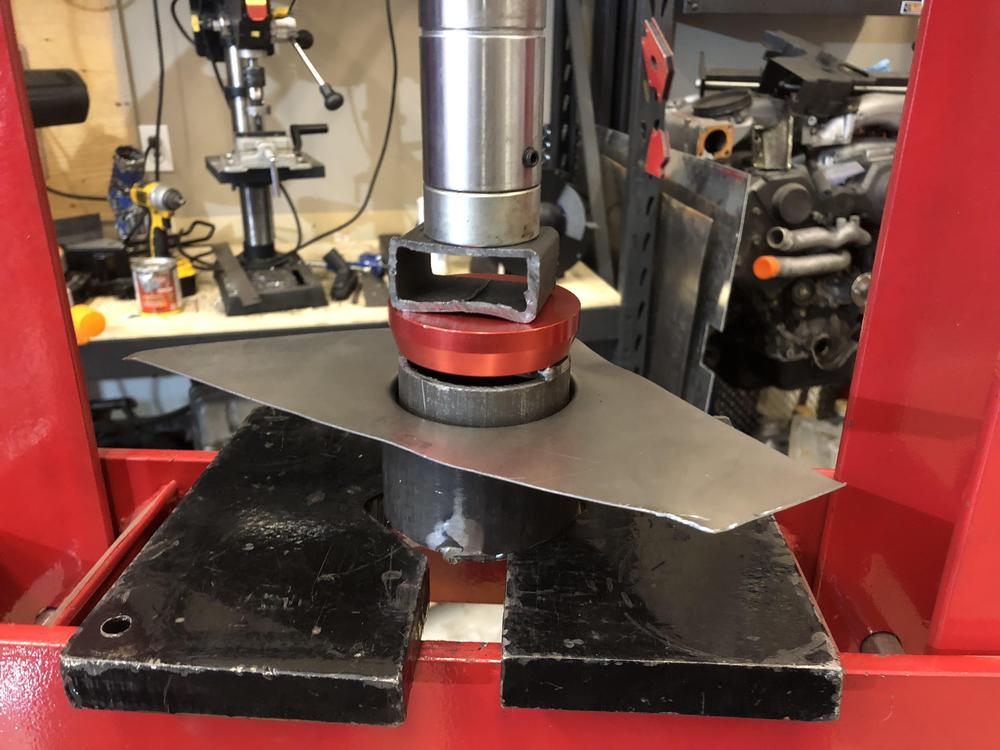

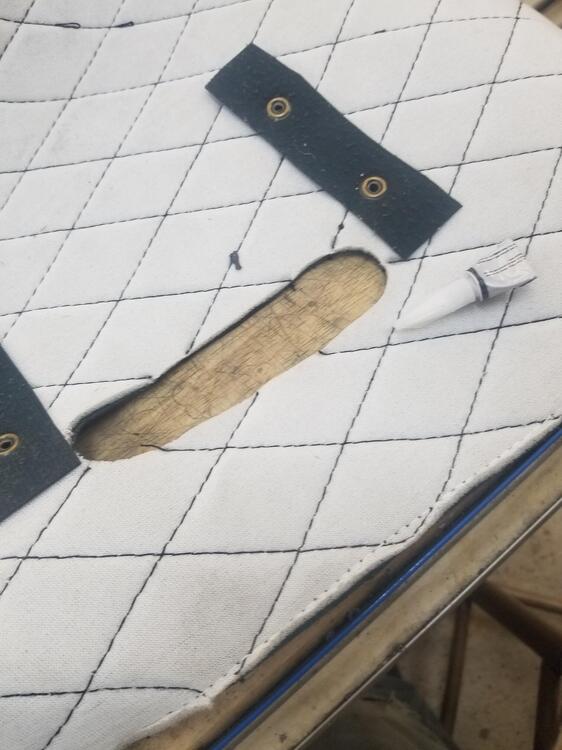

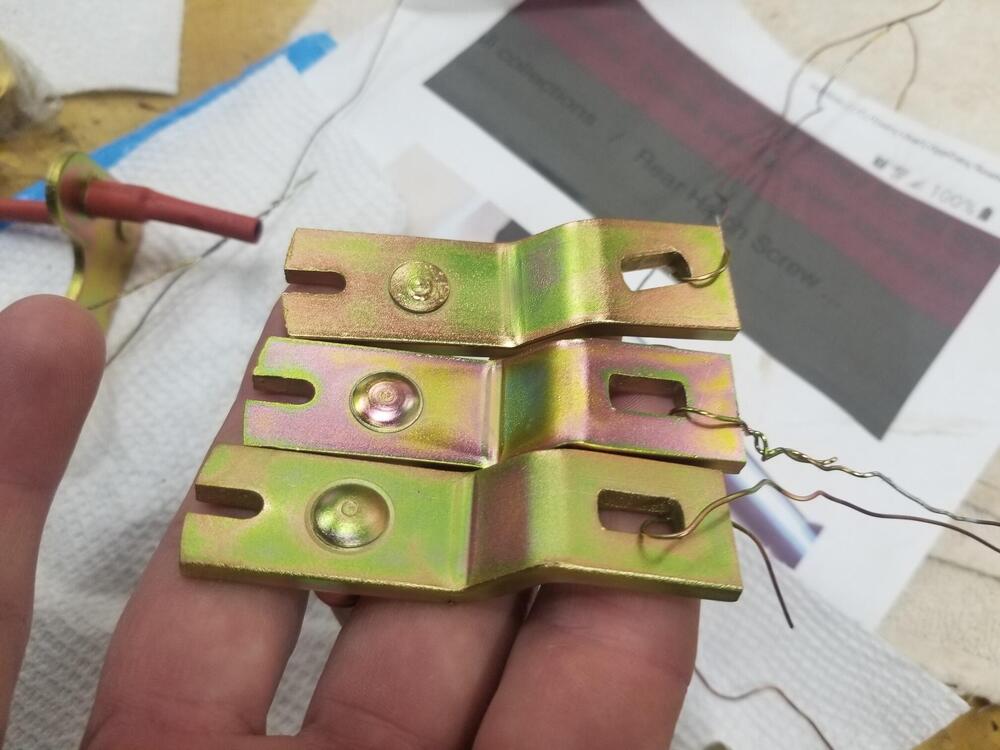

To replace them, I heated up a single edged razor blade (in a holder) with a propane torch, and cut through them on the back side. Then I just used a hammer and punch and tapped the remainder out. Pressing the new receivers/inserts in place is easy with a 10 mm deep socket and a vise.

The new ones come with smaller diameter screws. My original screws were re-plated and are in excellent condition. So I chose to use those instead. However, I had to open up the hole in the new nylon inserts to 13/64" and run a 6M X 1 mm tap through them in order to do so. Whether you use the original screws or the ones that come with the inserts, note that they do not have threads as received.

Next, I ran the original, as they are in good condition, headlight gaskets through my glass bead cabinet to remove overspray for the prior repaint job on the car.

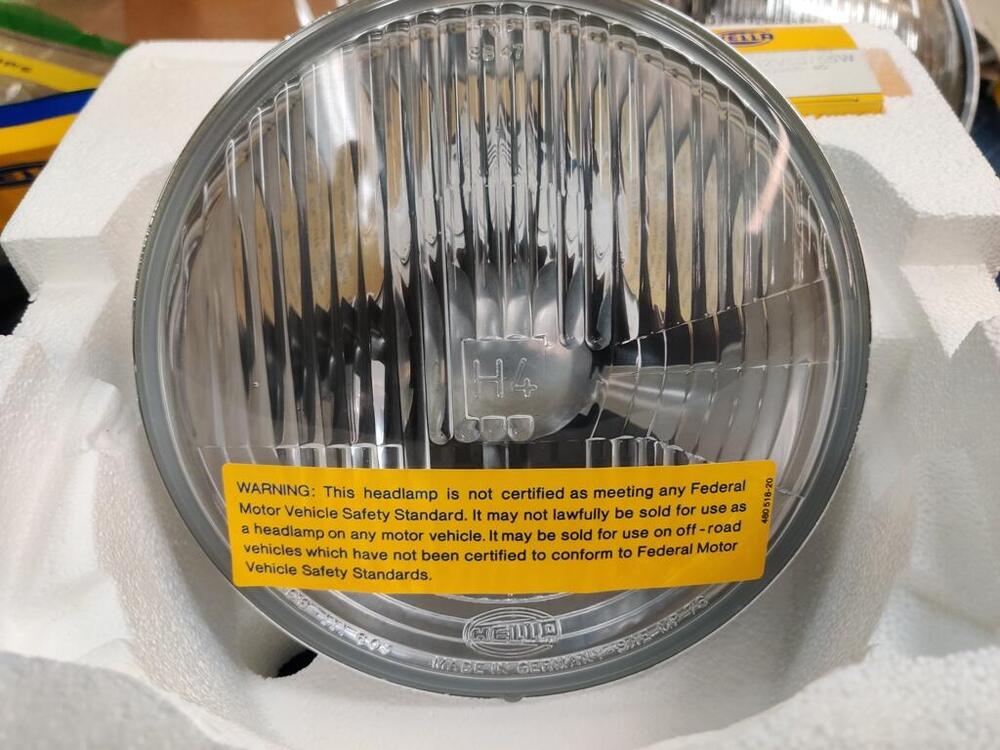

I got ahead of myself and installed one of the headlight buckets with just a regular sealed beam headlight (not even halogen), before I remembered I bought some Hella H4 housings and bulbs a couple of years ago.

I think these have some age on them, but that doesn't matter. So, I shouldn't bother with the H4 bulb - I should get some LED ones, yes?

It is surprising how little I got done today given that I put about 8 hours in. Oh well. Things are going well... if slowly.

Subscriber

Subscriber 22Points11,142Posts

22Points11,142Posts

.thumb.jpg.e1664e0e9defd214f234c31189f2af60.jpg)

.thumb.jpg.ff62026b4a968a9e54ee2240b4cb0848.jpg)

.thumb.jpg.6d8ac3aaa3aeb6b4811ff7adf654a4e9.jpg)

.thumb.jpg.cb8356069b41e27b5d55bcaaa1fbf2b1.jpg)

.thumb.jpg.78ffed0a76ccce5804c5c8d6a058aee4.jpg)

.thumb.jpg.821a841cab0f226941210e301fe91c26.jpg)