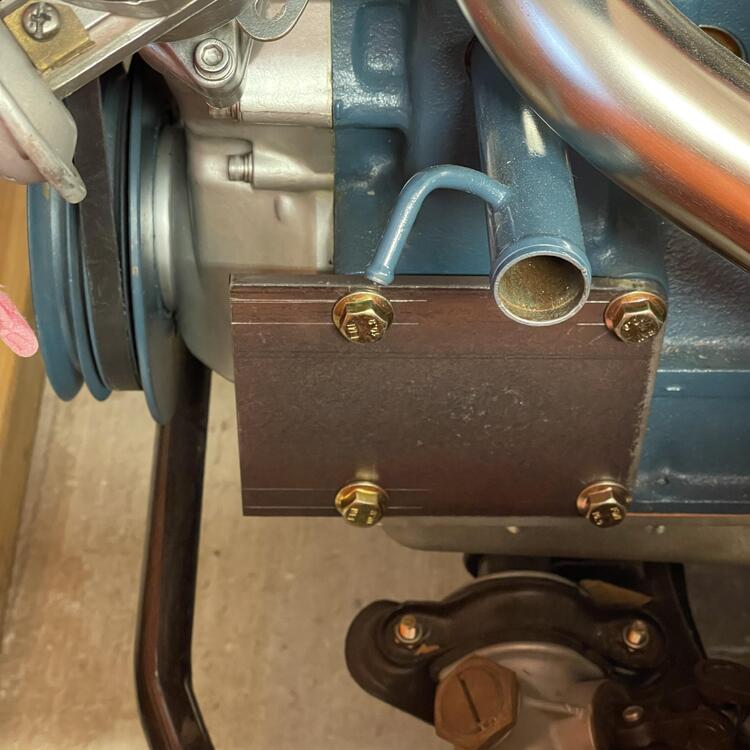

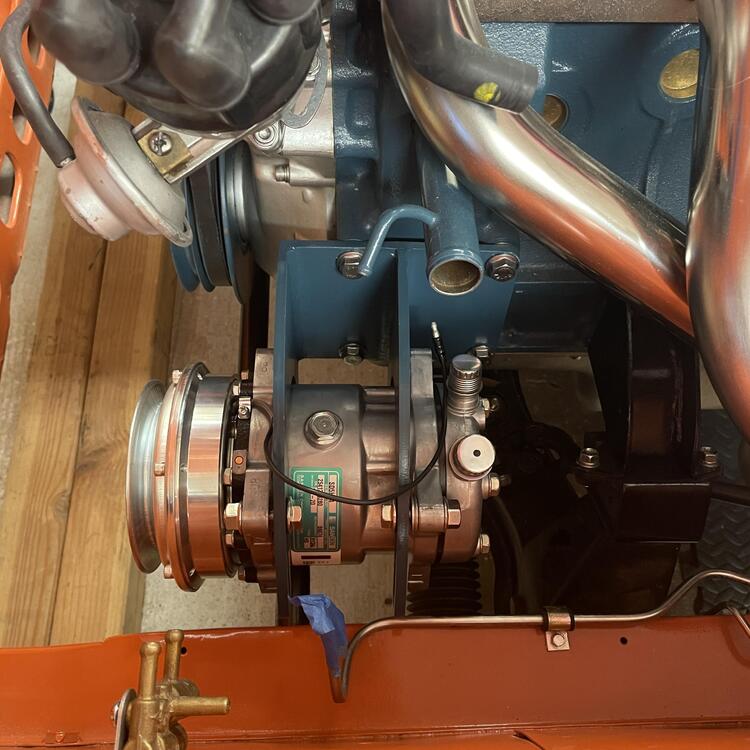

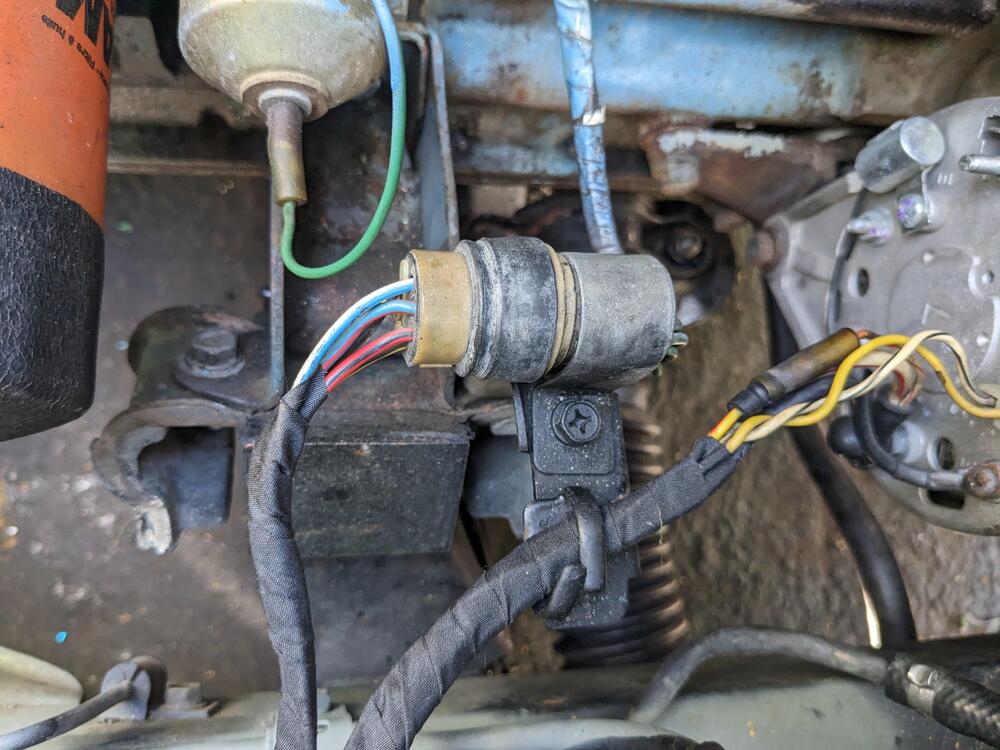

My Z is off the jackstands after I installed a new MSA exhaust and replaced the RMS, trans output seal and the speedo cable O ring.

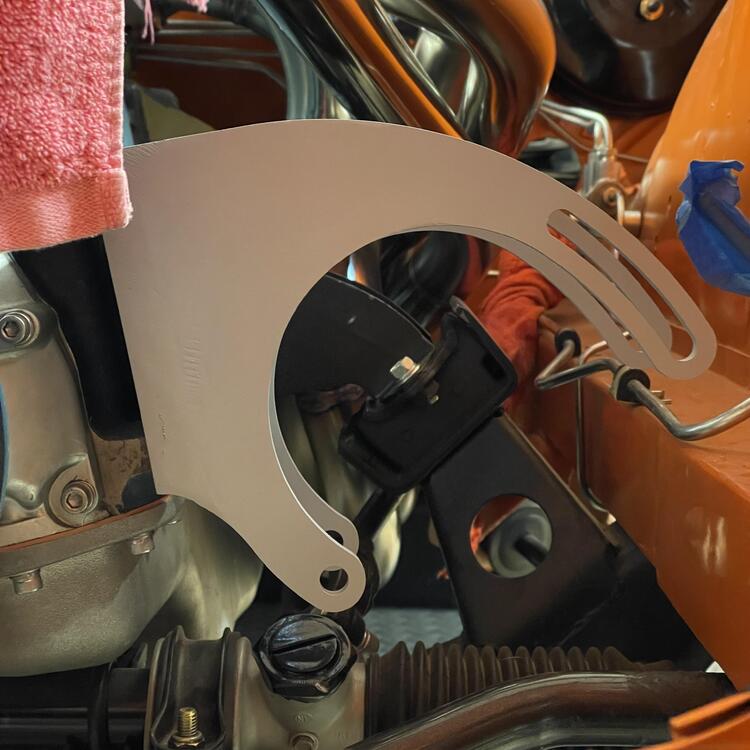

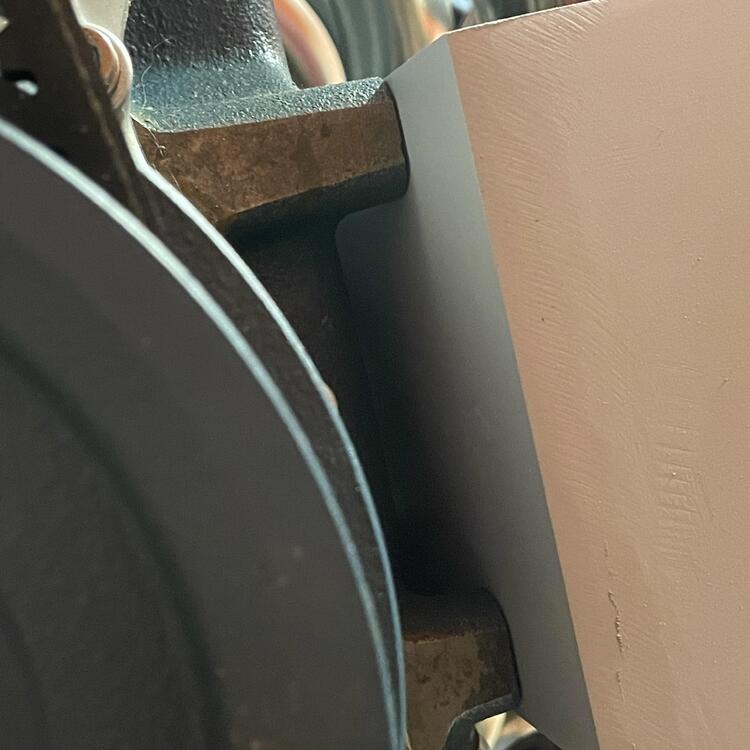

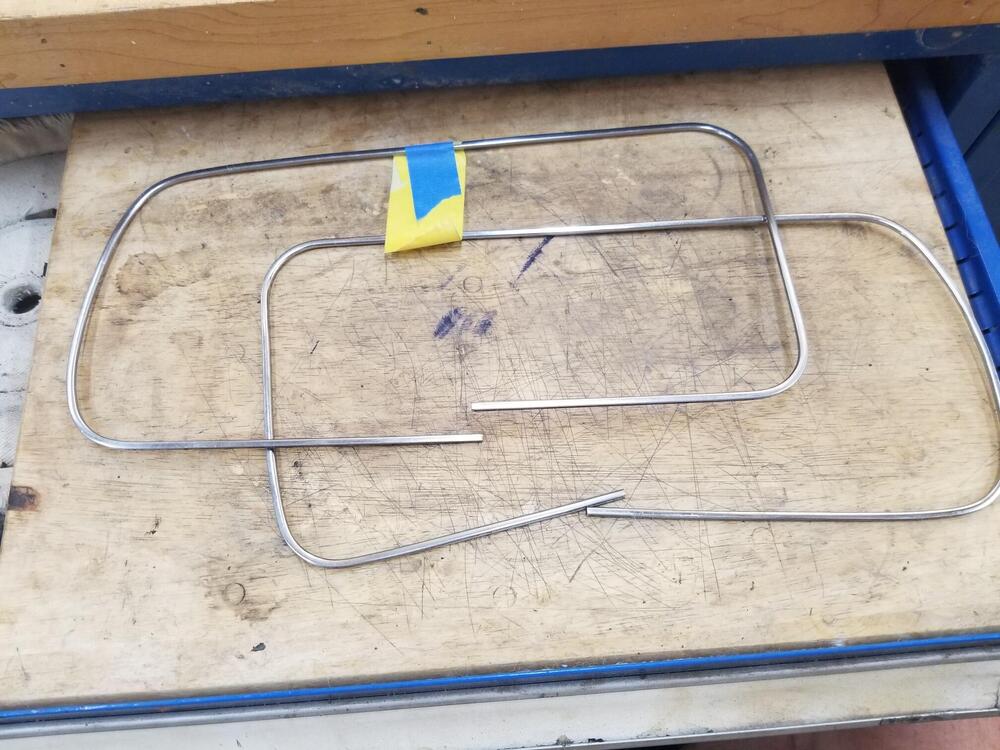

For anybody struggling to fit the MSA exhaust, after I cut 1" out of the Z bend pipe, and played with the rest for a while, I got it to fit very well. The front OE hanger that hangs the exhaust from the trans needs to be modified to fit the larger pipe and larger U bolt. 10 minutes with a die grinder and it fit great. I modified the bracket so that the top of the pipe was in the same spot so it didn't move up closer to the crossmember. The short straight pipe they give you goes behind the long pipe. If you try to put it behind the header, the angles are all wrong. Finally, the rear hanger is way too short for a 280Z. I had to add another strap.

This week, I will put collector car insurance on it, change the title over from AZ to MI, and get collector car plates. In AZ, they are made of copper. I can actually start driving it again!

Subscriber

Subscriber 7Points11,142Posts

7Points11,142Posts