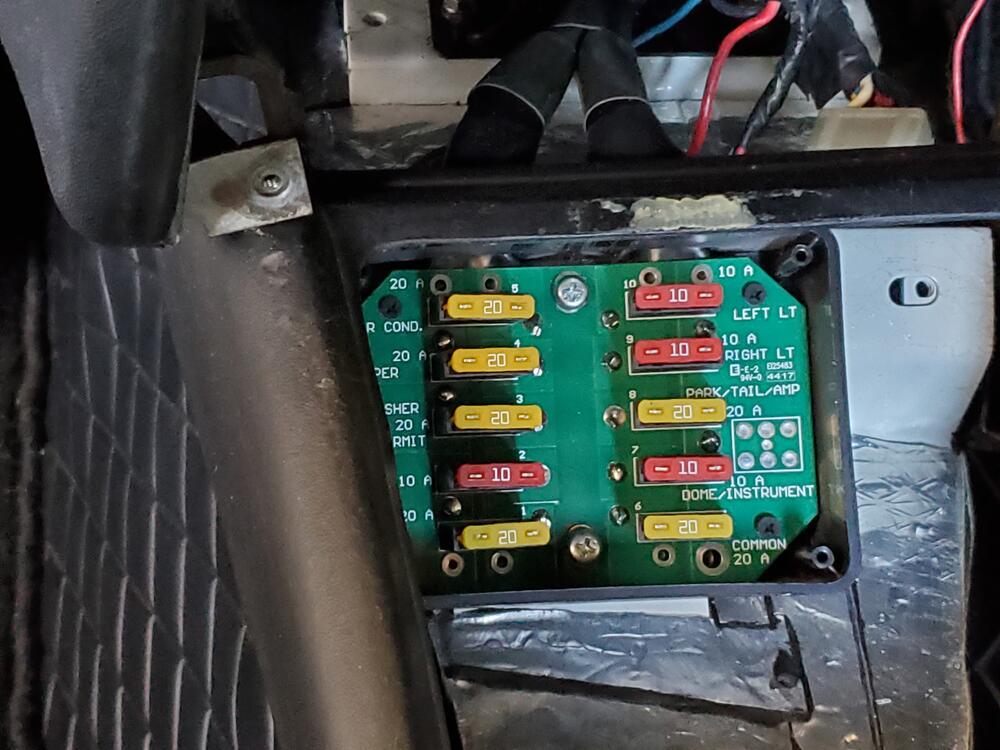

That all just the (cat-related) floor temp monitoring system that CA models had - there are two warning indicators in the center console, one for cat temp & one for floor temp (monitor is above rear muffler in cargo floor)

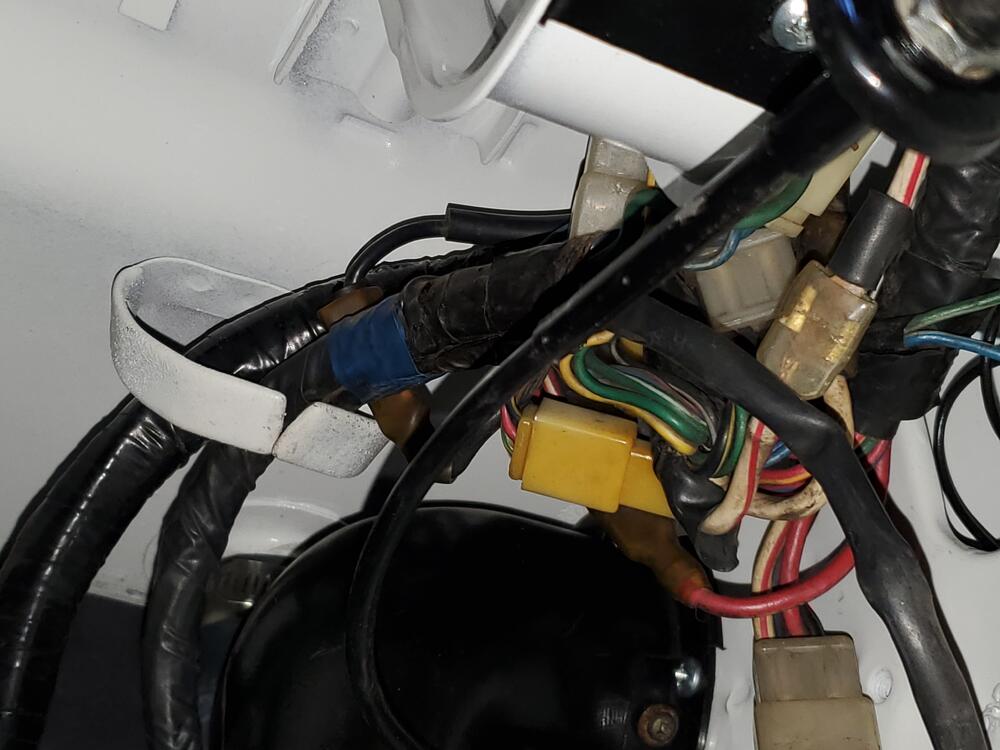

Yeah, all that fuel hose mess is going away. I have an assortment of Volvo fuel hose with the proper rating, I may also convert to quick release & nitrile lines in preparation for the VQ35DE conversion.

I'm not going to strip the floors now, just cleanup any loose material & spray fresh 3M Rocker Schutz & undercoat in exposed areas.

I'm vacillating on what to do with the exhaust - I may just make a new 2.5" rear section with new muffler that will be detachable ahead of the subframe. That way, when I do the VQ35DE, I can tie into that instead of having to make the entire exhaust from scratch. I don't think I want to go to 3" on the exhaust.

I have no use for all that shielding once I replace the exhaust, but I'm still going to clean it up.

I think for now I'm just going to do the bushings in place - the axle conversion I'll going to put off as I don't want the car to be down for very long, and getting the companion flanges machined to be concentric for attaching the adaptor flanges is a variable I can't control, time-wise. I need this to be roadworthy so I can take the Volvo pickup off the road to get moving on the V8 conversion. So, just bushings, struts & brakes for now. After that, I still need to make the AC work if I'm going to drive this for the summer & fall.

Subscriber

Subscriber 4Points2,733Posts

4Points2,733Posts

.thumb.jpg.077253cdb33db490f35afa214729dca8.jpg)