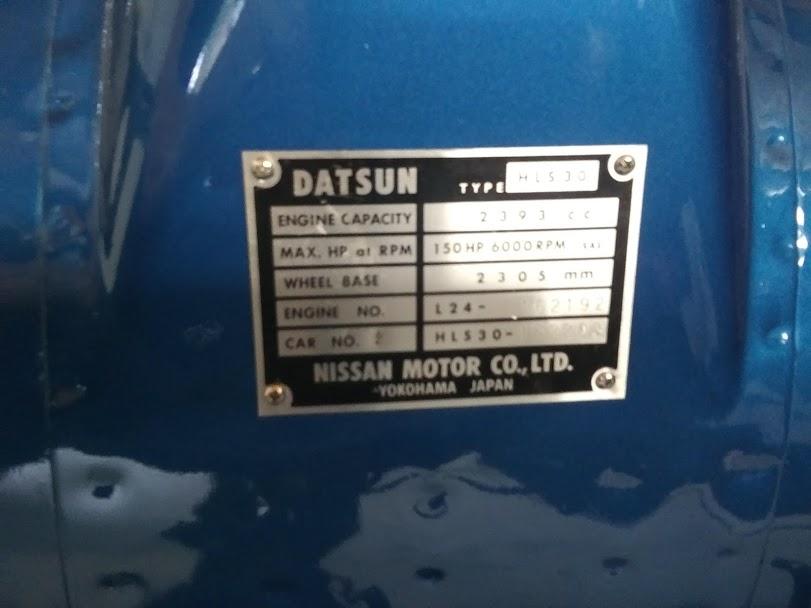

Unexpected update! Evidently "they had a window open" and I was told that if I wanted to inspect the work before color was sprayed, I needed to come next week! Various things aligned - I had taken today off to travel to Charleston, SC for a soccer tournament... and John, the guy that put me onto these painters was itching to go flying today. So, we flew to AL today and dropped in to check out the work they have done thus far. I talked with the two guys who have worked on it thus far, and all is looking good.

There is an issue with hood alignment, but they are hoping that when they install the hood springs, it will resolve. They had to straighten the belt line in a few places, align the rear hatch, and they found a hairline crack in the driver side headlight housing, which they fixed. I suspect I caused that crack the day before I delivered the car when I was assembling panels.

I asked again for "spray cards" of the 901 silver to be sent to me ASAP - next day or second day, as necessary. As things stand now, they may paint the car before the close of business next Friday! Or not. We'll see.

Subscriber

Subscriber 3Points1,282Posts

3Points1,282Posts