I think someone was here before me, so too late not to change anything.

I examined only one of the axles with regard to the arrows I mentioned at the beginning of this thread. The arrows pointed to a "flatter" of the four corners of the trunnion, but they were not drilled and tapped for grease fittings. The relationship was 90 degrees one to the other, not 180, or in alignment. Thanks for the tip about brass jaws.

I was able to get the snap rings matched up for each opposing journal pair. .062" was the most common size snap ring I needed to use. If I recall correctly, the new snap rings which came in the package with each of the new u-joints were of the following sizes: .060", .061", .062" and .064", .065", .066" There were 12 supplied with each u-joint - two each of those sizes. Oddly, .063" seemed not to be present. I carefully lapped two .064" snap rings to get the .063" I needed.

With the axle in the vise and using the dial gauge, I was able to confirm about .001" of free play axially for each direction on the trunnion. The u-joints feel a bit "heavy" in their movement. However, I am certain after very careful checking that the free play is what it should be. I could see the needle on the dial gauge move easily and then stop, as I applied pressure to move the u-joints up and down in their installed state.

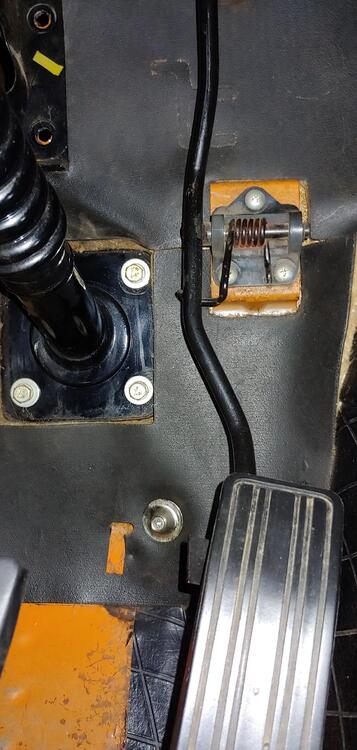

I may very well send the axles off for balancing. Since I am installing a 240SX transmission, I may need to get a driveshaft made also. If I can use my driveshaft as is, which may be possible, I will likely send it off for balancing with the axles.

Numbers indicate the snap ring used in thousandths at each location with opposite journals using same sizes, of course.

Subscriber

Subscriber 9Points11,142Posts

9Points11,142Posts Subscriber

Subscriber 6Points1,282Posts

6Points1,282Posts

.thumb.jpeg.a49983ec06b2e1d3191817a3ea7f78d1.jpeg)