Did someone mention V-3 kit?

The following is an edited version of an article I wrote for the Z Car Club of Northern Virginia many moons ago when we still had a monthly newsletter.

1972/73 found me working as a mechanic at a Datsun dealer in Bethesda, MD. We sold our first 73 240 to a member of the Redskins football team as a promotion. Only problem was it got towed back to the dealership for the next 3 consecutive evenings - so much for the promotion. This was in the early fall when the weather was still pretty warm and the car was exhibiting very rich symptoms. The owner of the dealership was pretty pissed as his name was starting to turn to mud with the guy who had bought the car with a lot of hype. Long story short, about a week later we were visited by 2 engineers from Nissan Japan.

We were the only dealer within bunch of miles of the Eastern headquarters in NJ that had a modern chassis dynamometer. For the next week or so these engineers and one of our mechanics spent most of their time with the Z in question on the dyno and on the roads surrounding greater Bethesda.

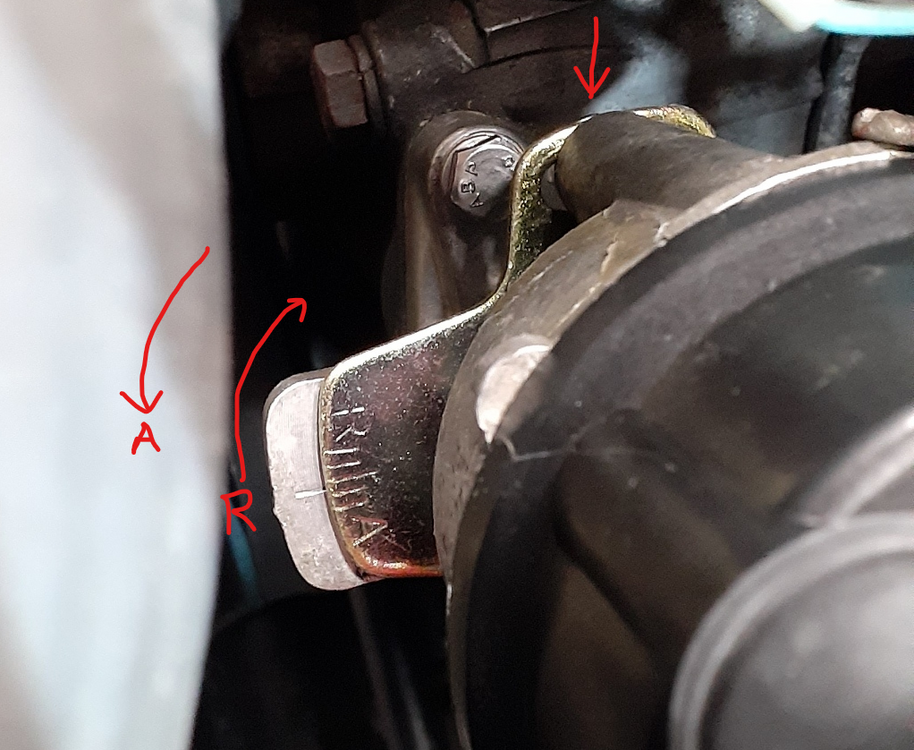

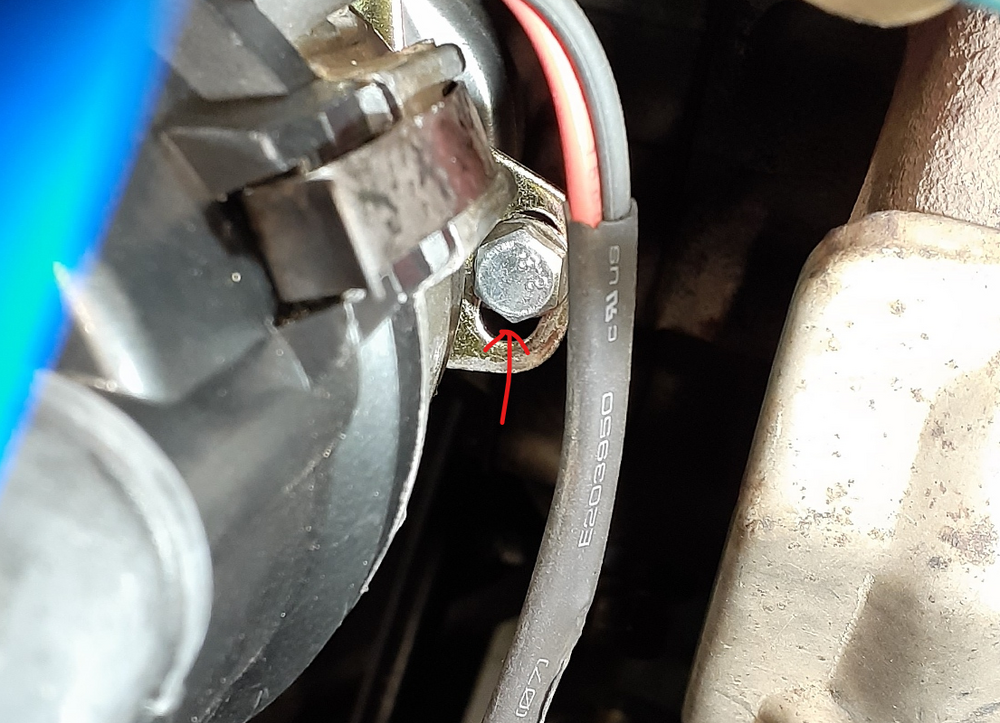

The result of their work was the V-3 kit. The kit included an electric fuel pump, fuel pump relay, asbestos like/aluminized engine compartment fuel line wrapping, carb floats and needles and a handful of other parts that, when the weather was warm, did little to address the problem(s).

Until Datsun/Nissan could start fitting the kits at the factory it was up to dealer mechanics to install the V-3s to those cars already in distributor/dealer hands. A real rush was put on the program and we started getting kits about a week or so later.

What was the problem? Adding an EGR system to the induction system raised under hood temps a great deal and moving the float bowls from the side of the carb to the bottom of the carb often resulted in fuel percolation as there was almost no movement of air in the very confined space between the float bowls and the exhaust manifold. .

The 1969-1972 240s vented the carb float bowls into the atmosphere through the air filter housing. The 73s and 74s couldn't do that anymore because of tightened emissions regulations. Those years vented the float bowl, now mounted in a confined and hot space, directly into the venturi. Now you had hot fuel vapors, unmetered, entering the venturi resulting in a very rich condition and LOUSY performance.

More later.