I noticed this tread and have a couple of comments. There are three clocks talked about here which are all different and have unique problems. The 74 260z was delivered with two clocks. Very early 74 the clock was the same as the 240zand the later clock was the 280 version. So we have the 240, 280 and what appears to be a VDO clock that are all different.

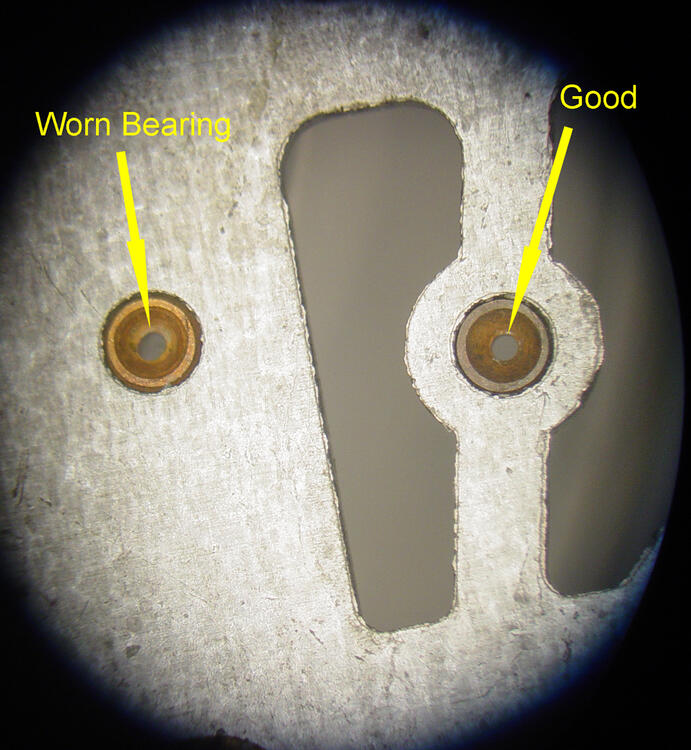

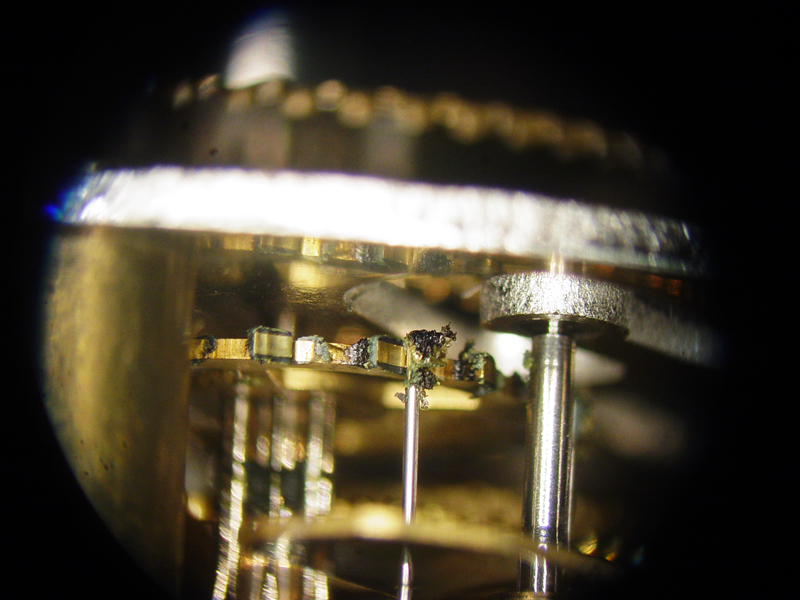

As far as the 240z goes if you put 21volts on any of the clocks you will cook the parts. This clock is very sensitive to dirt, grease and oil. If you look at the enclosed you will see what oil does to the clock gears. Oil collects dirt like a magnet and turns into grease. This is what stops the 240 clocks. Disassembly and cleaning is the only way to put the clock back in service for many years. Also, inspection of the bearing points in necessary or you will be disassembling the clock within a short time. Again the enclosed shows a worn bearing and this part needs to be re-bushed. All the oil in the world won't help this condition.

The 280z mechanism has very few bearing points and does not need any oil. The caps on the circuit board are the main problem and the spring is the second as well as the pink gear (missing teeth) on the enclosed. The other problem is the coils on the circuit board. Either of the two can be open,shorted, or incorrect resistance.

As far as cleaning DO NOT use the cleaning solution as mentioned. This is an old clock makes formula and is VERY VERY caustic / dangerous. This is as dangerous to your lungs as using epoxy paint without a respirator. The cost to make such a formula is about $60--80 depending on where you can get the items. Also, the ammonia(20%) can only be purchased at a chemical supply house and runs about $35 / quart! Also, this formula will destroy and degrade the nylon and plastic of your clocks. DO NOT use it. Isopropyl alcohol is the best solvent and yes it takes a little elbow grease, but it works.

I am not a clock maker, but I have repaired , cleaned and refurbished many grandfather clocks as well as hundreds of 240- 280 clocks. Oiling is something you should due for a grandfather clock as it has weights that drive the mechanisms that weight several pounds. With this kind of force on pivot points and bearings need to be oiled. Our Datsun clocks do not have this kind of force on the pivots. The 280z mechanical clock has several bearing that support pivots that are plastic and they do not need to be oiled.

The correct way to oil something, if you must, is one drop of oil on the bearing/pivot and wipe off all visible oil. Clock oils today are synthetic and have a much higher load and degree of temperature resistant than organic based oils of the past.

Hope this helps.

Ron