Zulaytr & Mike B,

I have taken the liberty of copying your posted photos, turning them the 'right' way up where necessary, and adding roman alphabet phonetic 'translations' of what I think they say in the hope that it might help us to understand this a little better. Hope that you don't mind.

Zulaytr,

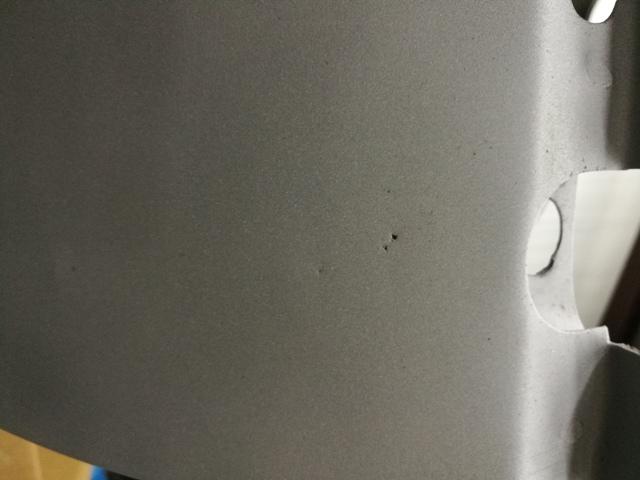

The Kanji on your dash actually reads as less than 'Spring Time'. In fact, it reads "Haru" - which is indeed 'Spring' as in the season of Spring ( Spring, Summer, Autumn, Winter in Japanese would be Haru, Natsu, Aki, Fuyu ) but could easily be part of another word or phrase, or even part of somebody's name.........

Unless we saw other examples that identified seasons ( Natsu, Aki & Fuyu ) then I'd hesitate to believe that the Kanji on your dash was reference to a season. If it did, how could that be of use on a production line that was churning thousands of these things out every month?

'Nen' and 'Ne' could easily be two ways of writing the same thing. One is in ( long hand ) Kanji, and one is in ( quicker ) Hiragana, and abbreviated ( ? ). Could they both mean the same thing...... ? Don't know.

Finally, 'Kokoro' or 'Shin' ( could be read both ways ) is Kanji, but seems ambiguous. A more formal Kanji character has been roughly scribbled out. Something has possibly been corrected on the component / sub-assembly?

A rough translation of 'Kokoro' would be 'heart' ( as in the feeling, rather than the organ ) and a rough translation of 'Shin' ( the other possible reading of this Kanji - although it is actually meaningless when used on it's own ) could also be 'Heart', the abstract feeling rather than the thing. It is not the correct Kanji for the similar-sounding 'Shin' meaning 'new' - which could have indicated a shortened form of a person's name..........

And that's what I have wondered about these in the past; Whether they were scribbles signifying the identity of the person who completed them or 'signed them off' - at whatever stage of the process ( could even be just the sheetmetal frame part......... ). Don't know. Some of them don't seem to fit in as possible names or even nicknames.

Interesting that they are situated in a place that is not covered by the vinyl, but is covered by the steering column when the dash is fitted in the car. That must be a clue as to what stage in the manufacturing process these graffitoes were applied, and meant to be seen.........

Alan T.

Subscriber

Subscriber 6Points2,733Posts

6Points2,733Posts