Everything posted by Captain Obvious

-

Wheel bearing noise

Yeah, that doesn't sound good. I don't think I would toss up as much of an urgent "don't go on any long trips" as SteveJ did, but you should get to that in the near future. Many people (including myself) have switched over to the ZX style nuts for the stub axles. Photo courtesy of Blue:

-

Why this forum is unique

I like it here too.

-

.01 Ring with Standard Piston

You care more about the circumference than the diameter. The difference in circumference between the 83mm and the 83.25mm ring is 0.785mm. If your current gap is .53 mm with the standard ring, then an 83.25mm ring would result in a .25 mm overlap. You would have to remove that overlap and then enough more to end up with the desired gap. That said, I have no idea if using the oversized rings would actually work or not. I'm just here for the math.

-

Maxima overload

The internets say it will work faster and more effective if you add a little salt to the vinegar.

-

Ammeter acting up

When I get a chance, I'll take another look at the wiring diagram and see if I can draw any conclusions. I still don't think you were really pushing 60A into anything. That's welding current.

-

Best add on A/C kit for 77 280z??

sorry, but that harness is installed in my car. I put some parts in for A/C just like you're doing. I installed the whole A/C control head with the 4-position switch and also swapped out my original blower resistor for the one that works with the 4-position switch. And that's the only A/C sub-harness I have, sorry. Another complication is that the 4-position switch has another feature built into it that deals with the A/C system specifically. It has an output pin that is essentially "The fan is not in the OFF position." And that pin is used to disable/enable the A/C system. You see, it's potentially damaging to the compressor to run the A/C if the blower motor is not spinning. You run the risk of slugging the compressor with liquid refrigerant. So they make sure the compressor will not run unless the fan is spinning. The 3-position switch has no such feature. So you can either "always just remember to turn the fan on when the A/C is running", or you can use the 4-position switch to interlock automatically and do that for you. After a lot of words above, the bottom line is... I recommend you get your hands on the sub-harness that came with the A/C cars and run the 4-position switch.

-

Best add on A/C kit for 77 280z??

I'm not completely sure what you're asking with the blower upgrade question, but.... The resistor is mated to the switch. If you have a three position switch, then you need a three position resistor. If you want to use a four position switch, then you'll need to pair that with a four position resistor. You can run any of the fans (original, Kia, Honda, etc) with either switch, but you need the proper resistor for the switch. As for the sub-harness thingie... It looks like this. This is the one for an A/C system: And here's a low detailed shot of both options for the sub-harness. A/C on top, non-A/C on bottom. If you look closely and count connectors, you'll notice that the sub-harness for A/C has more connectors on it. The extra connectors are for A/C specific items like the compressor control:

-

Brand new 'Quick Racks'

Brass is not really a good bearing material. What you want is bronze, not brass. I don't know if all the racks used the same bearing sizes, but Mike W bought a chunk of bronze and had some bushing cut at a machine shop. Info and dimensions (for the later 260/280 racks at least) here: https://www.classiczcars.com/forums/topic/48621-steering-rack-disassembly-and-refurb/?page=7&tab=comments#comment-540657

-

fuel pressure regulator location

I don't know if all the holley regulators are the same, but I have been inside one of the little low pressure varieties. I made some internal changes, made some new parts for inside, had some parts left over... That sort of thing. But since it wasn't for my car, I don't remember exactly WHY I did it. It all made sense at the time, but I don't remember the details as to why it was necessary. My vague notes indicate that I modified it to work on a downstream by-pass configuration. Here's the pictorial summary:

-

Ammeter acting up

I just doubt you were really stuffing 60A into the battery. If the battery only takes 100mA at 14.25 volts when fully charged (on my HF float charger), then I don't want to know how high the voltage would need to be in order to make it eat 60A. So getting off in the academic weeds... If you knew what the resistance of the shunt is. And you knew what the resistance of the ammeter coil is. You could calculate the current ratios. In other words, you could calculate "If there is 'X' flowing through the shunt, the meter will read 'Y' ". Armed with that info, you could back calculate what the actual system current was when your gauge was reading 60A? In other words, if the gauge current is supposed to be 1/100 of what the shunt current is, and the gauge was reading 60A, then the real system current was actually 600mA. And then if your clamp on gauge reads about the same, it'll confirm that's what happened? Maybe? Possibly? Like I said... Off in the weeds. The DC current clamp sounds cool. Maybe it'll shed some light. My prediction? It won't do anything wrong while you have the clamp installed. So just keep the clamp installed on the car. Haha!

-

fuel pressure regulator location

I believe the 240 has a similar restriction orifice to the 260. And about the fuel pressure regulator... I originally said it's dependent on the regulator design and I think I worded that all wrong. You can run the regulator in either dead-head configuration, or bypass configuration, but it depends on the rest of the system. So let me try again: If your fuel pump has enough flow capacity to power both carbs and still have flow to spare, then you can run the regulator in bypass mode after the carbs and send the extra fuel (bypass fuel) back to the tank. If your fuel pump does NOT have enough flow capacity to do the above, then you need to run the regulator in dead-head mode between the pump and the carbs with no return at all. But you'll need to make sure the fuel pump can deal with being dead-headed without overheating. Some pumps cannot deal with running in dead-head mode because they need fuel flow to cool the motor. Am I just making things worse?

-

Ammeter acting up

Yeah, intermittent electrical issues are the worst. And at some point, you just have to call it. So about the battery being a big load... The battery can be a big load if it's not fully charged. But if you're driving the vehicle regularly and the battery is fully charged, it's not much of a load at all. Like a capacitor that is fully charged to the supply voltage. It's essentially an open circuit. The battery does the same thing. I've measured the quiescent current into a fully charged battery (a float charger sitting at about 14V) at maybe a hundred milli-amps. And about starting the car... "But I crank the starter and draw 40A out of the battery for a short period of time." The catch is you just can't put it all back in as quickly as you took it out. The battery just won't accept the energy that fast. But in any event, I hope you fixed the issue and it doesn't come back. Intermittent electrical issues suck.

-

fuel pressure regulator location

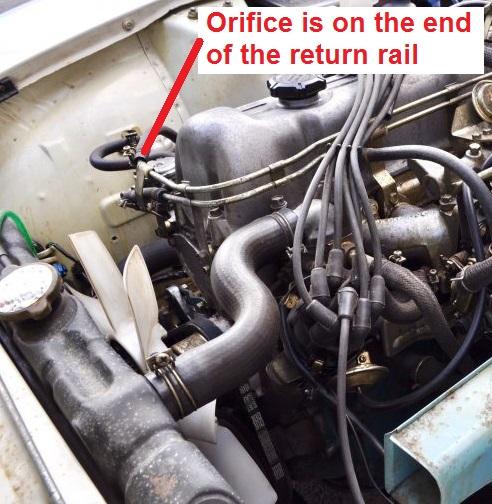

The restriction orifice is a necked down small-ish hole on the end of the return side of the fuel rail. Where the return side connects to the rubber hose above the fuel pump:

-

fuel pressure regulator location

I'm no regulator expert, but I think you need to determine if your regulator is designed for bypass configuration or dead-head configuration. That will tell you which way you need to plumb it. If it's dead-head, you need to put it in the supply line and (probably) cap off the original return line. If it's bypass, you need to put it in the return line in place of the stock restriction orifice.

-

Ammeter acting up

I haven't studied the wiring diagram really thoroughly, but it looks like the one side of the shunt (the white wire side) only goes to the fusible link that goes to battery (+), and the voltage regulator. I'm thinking that because of the way things are wired, with the VR out of the circuit, most of the current will find another path instead. Basically, the wires to the ammeter are self-contained. Those two wires originate in the shunt and go to one place and one place only... The ammeter. They do not make connection to anything else anywhere in the car. So one of three things is going on... 1) The shunt goes open and all the current tries to go through the ammeter instead of the shunt. 2) You really DO have 60A flowing through something. Since you didn't see smoke and everything seems to be working correctly, I doubt this one. 3) One of the two wires leading to the ammeter coil are shorting out to something else. Since the polarity seems to flip, I doubt this one too. Of course troubleshooting is always difficult from a distance, and that goes double for electrical issues, but that's what I got.

-

Starting Carb Conversion: Flat Tops to Paltechs

It looks like the newer design will bolt up. I'm kinda surprised. Here's a pic of the dimensions on what I have: Send me a PM and we'll see if we can reach an agreeable agreement.

-

Ammeter acting up

Hmmm... My first guess is that your shunt connections are (were?) intermittent. The ammeter is supposed to sense a tiny tiny fraction of the total current that is flowing in the system. It does that by letting the vast majority of the current go through the shunt, while the tiny remainder heads off to the gauge coil. It's a current divider based on the resistances of the shunt and the ammeter coil. But if the shunt goes open-circuit in the right (wrong?) way, all the current will try to go through the ammeter coil. Probably pegging the ammeter in the process.

-

Starting Carb Conversion: Flat Tops to Paltechs

If I get a chance, I'll take another pic today with a tape measure up against the bolt holes so you can see if it's the same as what you currently have.

-

Starting Carb Conversion: Flat Tops to Paltechs

That old flat-top part should get you out of the woods for now. It really wants a bearing support closer to the end, but I think it should be OK for now. So here's what I have. Question is... Will the pivoting mechanism mount to your firewall? Are the mounting holes in the same location(s)?

-

280z - Rear Bumper Term and Door Bumper Advice

Yeah, me too. After all the stuff I've screwed up, I might be an expert on some of it. Yarb, The progress looks good.

-

Floor Jack Question

Live long and prosper.

-

Best add on A/C kit for 77 280z??

If your car came without A/C, the four speed switch won't mate with the HVAC sub-harness. In order to change over to the four speed switch, you'll need the different blower resistor and HVAC-sub-harness. (Note that the four speed blower resistor also requires the different sub-harness.

-

280z - Rear Bumper Term and Door Bumper Advice

Haha! Well not for long! Keep screwing up like that and you'll soon be as experienced as the rest of us! Haha!!

-

Starting Carb Conversion: Flat Tops to Paltechs

Many different ways to lengthen the linkage, so whatever works easiest for you. If you take a good pic of the piece that mounts to the firewall, I'll snap one of the later version. If it looks like the new one will swap over as a bolt-up, I've got one here and a longer shepherds hook that I could part with. You could just bolt that in and go. I'll snap a pic of that if I get a chance and you're interested.

-

280z - Rear Bumper Term and Door Bumper Advice

That center hole is not a spot weld. I suspect that was a locator feature. So you drilled out about the only part that is NOT holding it on. Haha!! Not a big deal. Stuff like that happens.