Everything posted by Captain Obvious

-

Starting Carb Conversion: Flat Tops to Paltechs

Right. When you switch to the 240 style balance tube, you'll find that your old shepherds hook is too short. Not the most beautiful thing in the world, but you can cut your original in the middle-ish and weld on a piece of tubing to take up the gap. Here's one from a 74 260 as an example. I believe they changed the pivot mechanism that mounts to the firewall and the shepherds hook design between 73 and 74, so yours won't look like this. But the concept is the same: Extendo mod used on a 74 that switched to a 240 balance tube: And here's a pic after the welding is done and cleaned up a little and installed. Note the newer design throttle linkage pivot on the firewall. Seen on the right side of this pic: So I don't know if the newer design pivot will bolt right up to your firewall, but if it does, you could switch to that and a longer shepherds hook from a 280 or ZX.

-

Z's on BAT and other places collection

LOL!!! I'm really going to miss comments like that from 2020. Oh wait... Nevermind. We'll have a whole year of them in 2021, so it's all good!

-

Modified SU carb needles for L28

All I picture is Andy Kaufman.

-

Modified SU carb needles for L28

In addition to smoothing out variations in piston position. the damper prevents the piston from rising too quickly under acceleration conditions. The delay in the piston rise temporarily richens up the mixture just like an accelerator pump would. So the accelerator pump function may not be direct like the Weber's pump, but the intent is the same. There's a brief note about the function on page EF-19 of the 72 manual. There's probably other (maybe better or more detailed?) in other years FSM's, but that's the one I put my finger on first. And to answer your original question about the springs... The springs would affect the mixture under all conditions, not just acceleration. The thickness of the damper oil would only have an effect upon increased engine load, but the springs affect everything.

-

Front Sway Bar Support Plate Replacement

The front sway bar mounts to the frame with a thin piece of metal between the two. I'm not exactly sure what they were thinking when they put that thin piece in there, but here's what the originals look. Note that the shape changed over the years... The 240 parts is smaller than the 260-280, but here's what it looks like on the 260-280: Unfortunately, the pieces on my buddies 260 don't look so good. His plates are rusty and bent: So I had replacements laser cut out of 304 stainless. Nice new shiny parts: Hey, it's the little things, right?

-

Merry Christmas all

Hahaha!!! You French kiss your dog in the mouth! Sorry for the thread diversion. It's just good TV from the olden days.

-

Identify 280Z Terminal Type

I don't know what year they started, but my 77 used the MIC mark-1 connectors. Been a while, but if I remember correctly, that's what they used to connect the engine bay harness to other harnesses under the dash? And I think I was messing around with them for the same reason you are. Headlights.

-

Air / Fuel Meter Recommendations

Thanks for the details El Cheapo. Now I just have to wait for spring!!

-

Merry Christmas all

Merry Christmas to all, and to all a good night.

-

Merry Christmas all

Yeah, that's pretty far up there. Haha! Your mother sews socks that smell!

-

Z's on BAT and other places collection

Good. I liked that one. If I were buying, that's the kind of car I would be looking for. Unrestored, but unmolested. Used, but not abused. I didn't read any of the chatter on BAT, but the pics looked like they weren't trying to hide anything. No pretense, just an honest, well loved used Z with all the warts you would see on a normal Z car. I'd rather fix them myself than pay for someone else's work already done. Although, if the price for that kind of car is now up to 27.5K, I'm not sure I have the $$ to be in the market.

-

Air / Fuel Meter Recommendations

So El-Cheapo From The North, the sensor for your LM-1 looks like your normal O2 sensor? Threads and all?

-

Identify 280Z Terminal Type

Awesome. Glad they were the right parts! So I went back through my notes and I've purchased from Digi-key, Newark, Onlinecomponents, but never Mouser. I'm assuming I didn't go through the effort to set up an acct there, but it seems like maybe I should.

-

The blue 510

The 74 cigarette lighter is illuminated the same way. And same to you all and hoping to see you all again at a future ZCON!!

-

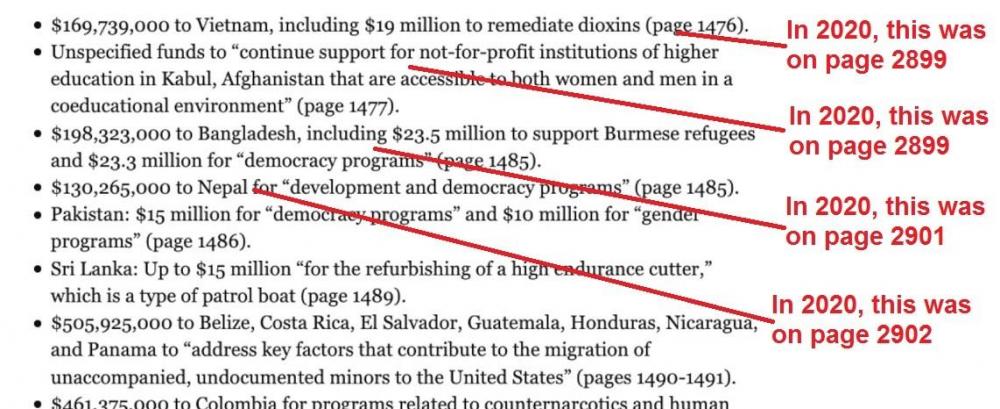

Ebay shipping time machine

I had one more thought about this appropriations bill thing and then I'm gonna go back to working on cars... I was wondering about the one side "using Covid as blackmail" thing to get stuff put into the bill other side didn't want. I found a copy of last years Consolidated Appropriations Act 2020. Last years version of the same big appropriations bill. Well guess what... That stuff did NOT get stuck in there with Covid. In fact, that other stuff was already IN there. The Covid relief stuff is new, but the rest of that stuff? Already there. Some of the numbers changed a little (presumably for inflation?), but the same language for the same things was already there. I found the first four items and stopped. I'm assuming the rest of them are all in there as well. So what's the point? The point is... It's the example of twisted misleading "semi-facts" that are being used to tell you what your opinion is. It sounds plausible or it wouldn't work. And it sounds like something terrible that one side forced on the other using Covid relief as blackmail, but in fact it was in there already. And it was approved before. The people who are complaining about these items now... They approved it last year, right? And they didn't flag it as a problem last year, right? And they've had a year to finish reading last years details, right? I didn't dig back further than last year, but I suspect much of that stuff goes back a number of years. Here's what I'm talking about: Makes me wonder why are they making such a stink about all of a sudden? Wasn't it just as much of a problem last year? Did they just get around to doing their job and reading it this year? Did someone suggest they could blame the other side for blackmail and nobody would actually read any of it and figure out that it's not true? Did someone above them tell them their opinion and now they're telling you yours? OK... I think I'm talked out. I think I'm gonna go machine something.

-

How to find original paint color for 240z

I wouldn't fault someone for saying "it's a Datsun color" or "it's an original color", but I would have a problem with someone saying "It's the original color" if they weren't sure. Far fetched example... All the remnants of the original have been removed. There's really no way to tell what it was. And Datsun didn't keep any records, so there's no way to check old documents. Seems like nobody would be able to prove one way or another. You paint it in an original Datsun color and don't get lucky and happen to accidently hit the color it was when it originally left the factory. But so what... Nobody would ever know for sure. Then you sell the car and a perspective buyer asks "Is it the original color?" You say "Yes." and the guy buys it. Then a week later he's at a car show with his new purchase and someone recognizes the car as being his old Z car "he bought new back in the seventies". And pulls out the old dog eared photo of the car back then. Wearing a different color. Far fetched? Of course. Possible? Of course. Fraud? Of course.

-

Ebay shipping time machine

That's excellent. Love it!!

-

Ebay shipping time machine

But seriously though, the way the large bills like that are done is a problem. Lots of pages, not enough time to dig down into the details, and people sticking things they want into it and saying "well if you want this other stuff, then you'll have to agree to this stuff too." It's an antique problem. For example... The stuff on the previous page that people are complaining about now has been around for a long time. I didn't read the whole thing, but it looks like most of it al stems from the Foreign Assistance Act of 1961. So it sounds to me like the people complaining about this stuff (now all of a sudden) have had about fifty years to read it and do something about it. They cherry pick plausible sounding sections and twist them to support their opinion and then tell you that you should agree with them. It has to be plausible sounding or it wouldn't work. It has to be close enough to the truth to sound good or it wouldn't work. But it's all twisted misleading facts. Alternate facts. Propaganda. Both sides do it. So I don't know what the answer is, but the first thing to do is to stop being told what your opinion is. Shut the sound on the TV off. I give more credence in what they're willing to put into print than what comes out of their mouths. There's still slant to one side or another there, but not as much as the words they speak. If they're confident enough in what they want to tell me, they'll write it down. And most important of all? Stop getting your opinion from people on twitter or facebook or websites.

-

Ebay shipping time machine

!! Well if those are the my two choices, I'm much better at lurking in the background and saying bunches of words that in the end really mean nothing at all. I can say lots of stuff without ever being able to be pinned down on any of it. Kinda like Teflon. I can also interpret and defend pretty much anything. Your Highness is like a stream of bat wizz.

-

Ebay shipping time machine

Forgot... All of the stuff highlighted as problematic on pages 1476 to 1500? All of that stuff is in the Department of State part about funds appropriated to the president. DIVISION K—DEPARTMENT OF STATE, FOREIGN OPERATIONS, AND RELATED PROGRAMS APPROPRIATIONS ACT, 2021 TITLE V - MULTILATERAL ASSISTANCE FUNDS APPROPRIATED TO THE PRESIDENT INTERNATIONAL ORGANIZATIONS AND PROGRAMS So for future reference... The Covid stuff starts on page 1815. So anything on prior pages is not part of the "Corona Virus Response And Relief" section of the document.

-

Ebay shipping time machine

You have highlighted what I believe is the biggest part of the problem right now... The twisted, misleading misinterpretation of info fed to you by the people whispering sweet nothings in your ear in your own corner. They tell you what to believe, and how you should react to it. Did you actually read any of the bill? Did you actually read ANY of it, or are you simply accepting the summary of the people in the media (radio/TV/web ) and accepting their interpretation hook, line, and sinker? Why do I ask such a thing? Because the whole bill.... "This Act may be cited as the ‘‘Consolidated Appropriations Act, 2021’’ " is a far reaching budget bill that is mostly not about Covid at all. It's about a whole bunch of other stuff that was being voted on regardless of Covid. There are only two sections that pertain to Covid, and guess what... All of those page numbers you referenced above??? None of them are in the Covid relief sections at all. So all those people saying "Look at all the pork stuck in the Covid bill!!" Clearly haven't read it either. First of all, because it's not "the Covid bill", it's the "Consolidated Appropriations Act, 2021’’ , and second, All the parts someone told you that you shouldn't like aren't even in the Covid portion of the bill. What we need is more independent educated thought instead of having our opinions fed to us.

-

How to find original paint color for 240z

Short answer. No. Medium answer. No. How can your conscience even allow you to ask such a thing? Long answer: No. If you pick a factory looking color (just because you like it) for your respray and then find out later you got lucky and it WAS actually the original color, then you could say it's been "repainted in the original color". You can still never claim it's the original paint. But if you never figure out what the original color was, you can never be sure if it was repainted in the original color, so you can never say it's the original color. Even if it's a factory looking color. You just cant. Ever. Best you could do would be to pass the buck. Something like "I couldn't figure out what the original color was, so I had the car evaluated by an expert on such matters and he said he believed the car was "nnn" color. Here's his credentials and his report with the details."

-

Air / Fuel Meter Recommendations

Gotcha. I'm sure I could figure out something for that. So I never looked real closely at the business end of your sniffer. What does the sensor look like? Just your normal threaded O2 sensor mounted on that bracket? Or is it a different style sensor that was never intended to be threaded into a bung?

-

Air / Fuel Meter Recommendations

Thanks for the info. I've had a procto like that done to my car by Dr. @240260280 with his LM-1. The LM-1 (and it's successor the LM-2) are designed to be used that way and not tied to any specific vehicle. The analog gauge I bought is intended to be installed in one vehicle and left there. I'm just wondering if things like the heater control are robust enough to be able to deal with being so far downstream from the engine heat source. That kind of thing?

-

Air / Fuel Meter Recommendations

So I got a question about my new A/F meter... Can I stick the O2 sensor up the tailpipe and use it like that for a couple minutes? Instead of welding a bung in? I mean, I wouldn't expect it to be as accurate if I used it the way it's supposed to be used and had the sensor installed way up by the engine, but just to test things out and see if it works? Cool sounding idea? Bad idea? Dangerous idea?