Everything posted by Captain Obvious

-

First start today!

Well good luck with sorting the carb details out and I'll keep you posted if I offer up public services. I've currently got carbs all over the workshop, but none of it is paying work. Haha!! As with most things I do, the money always seems to go the wrong direction! Haha!

-

Identify 280Z Terminal Type

Yeah, those part numbers look promising. Seems maybe I didn't look hard enough? Haha! According to the documentation I have, the 170221-1 is a Mark-1 male tab... Tin plated brass, 20-14 ga wires. And the 170286-1 is a female socket... Tin plated phosphor bronze for the same wire gauges 20-14. The connector housing part numbers you posted didn't show up in the little amount of documentation I have, but they are close to other numbers that did show up. Meaning they probably are Mark-1 and just have different cavity numbers or something. For example, 172024-1 did show up as an 11 position housing. So keep us posted when the parts get there. I'll dig out my Mark-2 parts when I get the chance and see what part numbers I ordered. Not that it really matters, but.....

-

Identify 280Z Terminal Type

If I can figure out where my notes are, I'll let you know what MIC contacts I already bought. You know.... Some of the wrong ones.

-

Identify 280Z Terminal Type

Well you really need to figure out if it's Mark-1 or Mark-2 you're buying because the Mk-2 stuff will not fit into the Mk-1 shells. Been there, tried that. Doesn't work and I can send you some if you want to see them. I dug around a while ago and couldn't find any Mk-1 stuff*. And in a feat of desperation, I did buy some of the Mk-2 stuff just to see what would happen. As I remember, there was no Mk-1 stuff at DIgikey, but I may have turned up something at Newark or Onlinecomponents. And... If you DO manage to find some Mk-1 contacts, buy some for me too, OK? It sounds like you are trying to do some of the same headlight stuff I did a couple years ago. In the end, I bought a whole engine bay harness and stripped out the wires (with connectors already attached) from that one. It had previously been hacked up some by a PO so I considered it a cadaver and didn't feel too bad about completely stripping it down. * At least in small quantities... I think I remember finding some of the contacts in full rolls, but couldn't justify the cost of buying the whole thing.

-

Identify 280Z Terminal Type

-

Identify 280Z Terminal Type

AMP - MIC Multiple interlock Connectors MK-1 The mark 2 (MK-2) stuff is easy to find but it won't work. The older MK-1 (Mark-1) is difficult. I'll take a look through my notes, but I don't think I turned up a viable source for small quantities of those.

-

First start today!

Yeah, it sounds like you're definitely in the market for a new pair of needles, and maybe a pair of nozzles as well. Material removed by corrosion will wreak havoc on your idle mixture. And if there's pitting on the needle, it's certainly possible there's the same kind of corrosion on the nozzle. That may explain why the needles fixed one carb, but not the other. As an example... Here's a pair of nozzles. One enlarged by corrosion and another with an accurate original sized hole. The corrosion ate away so much of the material that I can see the difference with the naked eye. At idle, it takes a very small gap to make a huge difference. So...... Weren't your carbs rebuilt? Sold to you in good working order? Slap-em on and go? Might there be some negotiation and relief there? And as for swapping and mixing and matching parts between carbs... I think it's OK as a test (like you've done), but I would want to keep the original pistons and chambers together with the carb body they came from. You could possibly move the pair (both piston and chamber) over to a different carb body, but you would have to re-align the nozzle. I wouldn't trust that it would line up after moving to a different body. But the best thing would be to just keep them together on the same body. I should go into the carb rebuild business.

-

First start today!

What is the history of the nozzles? And who did the alignment of the nozzles after the rebuild process? Is that something you did, or did they come to you already aligned?

-

First start today!

Swapping in a pair of known stock needles would be a good test, and something relatively easy to try. I know you said you are already positive that your float levels are on target and your chokes are not sticking down at all. And with those two things not causing a problem, I'm having a hard time coming up with a scenario that would result in running rich without some sort of damage to a nozzle or a needle or a wrong part installed. Like I said, lean is easy. Rich is more difficult assuming you have already ruled out the easy ways to run rich (float levels and sticky chokes).

-

Advice on Recent 1978 280Z Purchase

I agree with the above about the paint. If that's original paint, I'd try hard to preserve it. I also agree about the tranny... Swap it for a manual, but keep all the old parts. So I'm surprised it didn't go higher as well. I'm thinking the high prices for Z's hasn't gotten to the 280's yet. And lucky for you! Beautiful car and you stole it!

-

First start today!

The factory standard needles are N-27, but a lot of people install SM's instead. That decision works out well for some people and some others report running rich. The number is either stamped or inked onto the hilt and is only able to be seen with the needle removed from the suction piston. However, if they are inked (and not stamped), the ink printing is pretty fragile and is often destroyed with handling or chemicals. In other words... It would not be unusual for you to pull the needles and find only remnants of the number stamp and not be able to tell what they are from the ink printed mark. It's easy to make the carbs run lean, but it's usually a little more difficult to make them run rich*. To run rich, it takes deformation of a needle or a nozzle, or the installation of incompatible parts. Did you ever get in touch with Paltech and ask what needles he used? * Assuming, of course that the float levels are OK and the nozzles are not sticking down with the choke.

- 1976 280Z Restoration Project

-

Forwarded to the North

Actually, it was more like this: https://youtu.be/YdElbI77IfY?t=32 Haha!!

-

Forwarded to the North

Haha!! Not me, but I looked pretty much like that! Only cooler. And slower.

-

The blue 510

LOL! You and me both! I can also picture Granny frantically trying to cut the power before any more damage occurred!

-

Just Another Damned Z Car Project Thread

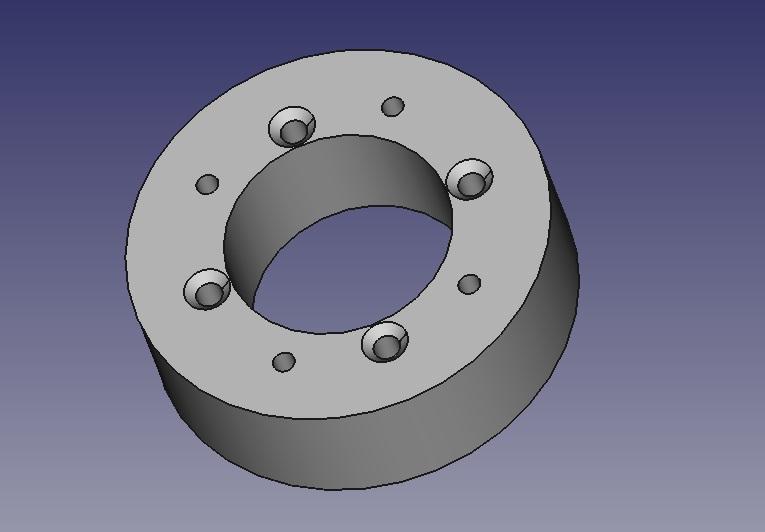

Good. And since I'm not a pain, maybe I just need to try a little harder. So using my (admittedly incomplete) understanding, here's a reality check of what the adapter could look like. 130mm OD and 70mm ID. I tossed in some countersinks too and it highlighted a potential issue. With a 70mm ID, there might not be enough meat for the countersinks. If that's the case, you might have to resort to a counterbore instead. In any event, here's what I whipped up:

-

Z's on BAT and other places collection

I wonder where this one will end up. Looks to me like a typical well loved and well used (but not abused) Z from a sunny part of the country. New paint covering worn out faded sun baked paint. Reasonably fitting dash cap covering a presumed sun-baked cracked dash. Missing emblem on the rear. Ill fitting dry-rotted weather stripping and lower door bumper hanging out of it's mounting holes. Holes in the seats (both of them, which IS a little unusual). Sun baked and faded rear carpet. Cracked A pillar trim and console mounting points. Spongy sun baked steering wheel. New fuel pump (which could be indicative od issues). And so on and so on. Nothing unusual and nothing irreparable. Worn (loved), but unmolested. Would just take money. The underside looks intact. Everything else can be bolted on.

-

Z's on BAT and other places collection

Agreed. The fabric and plastic rot seems to be the exact same M.O. as what's left of the blue one. I still think an extraterrestrial pathogen may be involved.

-

Just Another Damned Z Car Project Thread

Well I'm sure I'm just becoming a PITA at this point, but I got some questions about your adapter... First, why the two different sized holes? And if the answer is "the larger holes are clearance pass-thru holes for the screws into the intake manifold and the smaller holes are going to be threaded to accept bolts to hold the new throttle body", then there's a problem... You have the holes swapped. The holes on the smaller circle should be the pass-thru clearance holes and the ones on the larger bolt circle should be threaded. Other question is I don't see the countersinks for the heads of the screws to attach to the intake manifold. Are you just going to put those in manually after it comes out of the CNC? Same with the threads for the other holes? Sorry for being a pain!

-

Shifter Lever Bushing P/N ??

It just seems like a lot of trouble for a little bit of vibration. Not saying that's not it, but just that it's a lot of trouble for something they lived with just fine for the first nine years. So any time you change gears from forward to back (like from 3 to 4, geometry says the vertical distance between the center of the pivot pin and the bottom of the plastic nub on the lower end of the shifter shaft changes. What is it that accounts for that? Is the hole the plastic nub fits into extra deep? Deeper than it needs to be to account for that? Not sure I'm explaining that well without pics. I've replaced my bushings, but that's as far as I've had to go into the transmission. Thankfully.

-

Air / Fuel Meter Recommendations

There are several graphs like that in @blodi thread where he's trying to tune his Webers: https://www.classiczcars.com/forums/topic/56375-weber-selection-and-initial-jet-tuning/ I don't know how applicable his Weber graphs would be to your round tops, but for example, they look like this:

-

Forwarded to the North

Woof. Flying that mess doesn't sound like a lot of fun. Yeah, thankfully I got that final drive in that we were talking about. I meant to get in touch too, but every time I remember, then I forget again. It was nice final drive. Got gas, and then burned a couple gallons of it.

-

Spazstix Ultimate Mirror Chrome

Maybe it's just me, but I have never, ever, ever, never seen anything come out of a spray can that even barely resembled chrome. Even if it has "chrome" in the name somewhere.

-

Shifter Lever Bushing P/N ??

Wow. That's a lot of complexity for NVH. Are you sure it doesn't have anything to do with something more complicated than that? Reverse interlock or something?

-

280Z double floor removal?

Yeah, perfect. Just like that. I'm pretty sure you could hit the brown note with that much woofer!!