Thank you all for your comments regarding the suspension and the carb restoration. I have some good ideas now how to proceed. Vapor or dry-ice blasting seems to be a good solution. For the moment, they will remain in the box until i completed some other projects.

So a few days ago, I got this delivery of a Nissan Factory adjustable Competition / Sports option / NISMO suspension set, and I finally found the time to do the research.

First some Details, I got the two sets (front and rear) from two different sellers in JP, and it's a lucky coincidence that they actually fit / belong together.

The Part numbers are:

Front: 54303-E4622 & 54302-E4622 (Atsugi)

Rear: 55303-E4622 & 55302-E4622 (AMPCO)

On all four strut housings, each of the two platforms / adjustment rings are adjustable in height, and none is fixed, like they are on some other kits.

I assume that those sets were made by both Atsugi and AMPCO, that's why they have two different brands stamped on them, as most factory suspension for the Z was available from both suppliers at the same time.

The suspension set is listed in the January 1978 US sports option catalogue as "Gas variable type" and you can also see the Spring length of 171,5mm (front) and 205.5mm (rear).

The same set is also listed in both Marc and September 1978 Japanese sports option catalogues. It is also mentioned that those parts are approved for Group 3 / closed circuit racing and are harder than the factory suspension setup and allows you to lower the car.

The older race and rally preparation manual still lists the predecessor with the end numbers -E4621. Please note that the springs remained the same -E4621, even with the new -E4622 suspension.

As the older -E4621 is also listed in the March 1976 Competition parts catalogue, my guess is that this kit was introduced around in 1976 or 1977.

According to Alan Thomas, the term "gas filled" refers to a system where the "open design" dampers are oil-filled but gas-charged to help stop the oil from foaming during heavy race use.

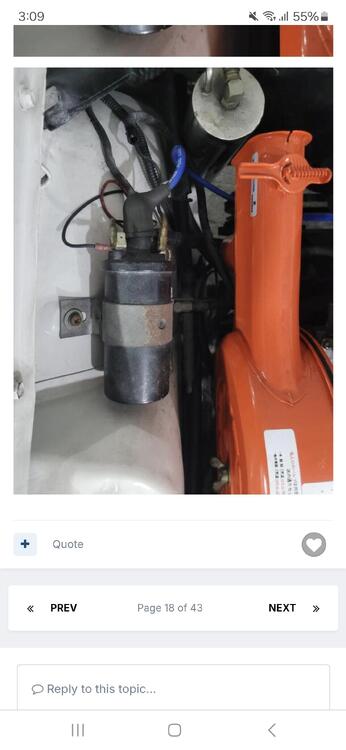

Unfortunately, the previous owner opened the rear suspension and now that gas is gone.

See here for more details on the open / cartridge strut inserts comparison: https://www.jdmjunkies.ch/wordpress/2017-01-19/240z-the-ultimate-guide-to-factory-suspension-and-options/.

According to Alan, there are companies that add a threaded hole to the upper strut section with a valve, so you can add gas again later. But he also mentioned, that the Gas is only really required for heavy race use and it will work without it.

Alan was also kind enough to share this photo of the factory gas filling setup / tool. To be honest, i don't really know how it works but it looks nice 🙂

You may have noticed that the front struts came with these additional aluminum spacer disks.

According to the above competition manuals (Part no 12), those were used on two-seaters built after 1974 and all four-seater cars, but they were meant to be used on the Rear suspension of the car. It appears that people used them also in the front to gain additional ride height.

The competition manual mentions that they are made from aluminum (which mine are) and are 20mm thick. I quickly measured the thickness, and it appears I was lucky to get a free set of probably rare Nissan competition spacers included with my suspension.

Remember that mystery adjustable suspension I bought a while ago? I never figured out which car it belongs to. It seems it's not listed in any of the competition / NISMO / Sports option catalogues i found.

But now, i finally got to compare them, and it appears that it's definitely not for the 240Z / Fairlady Z. (Left = Mystery, right = 240Z)

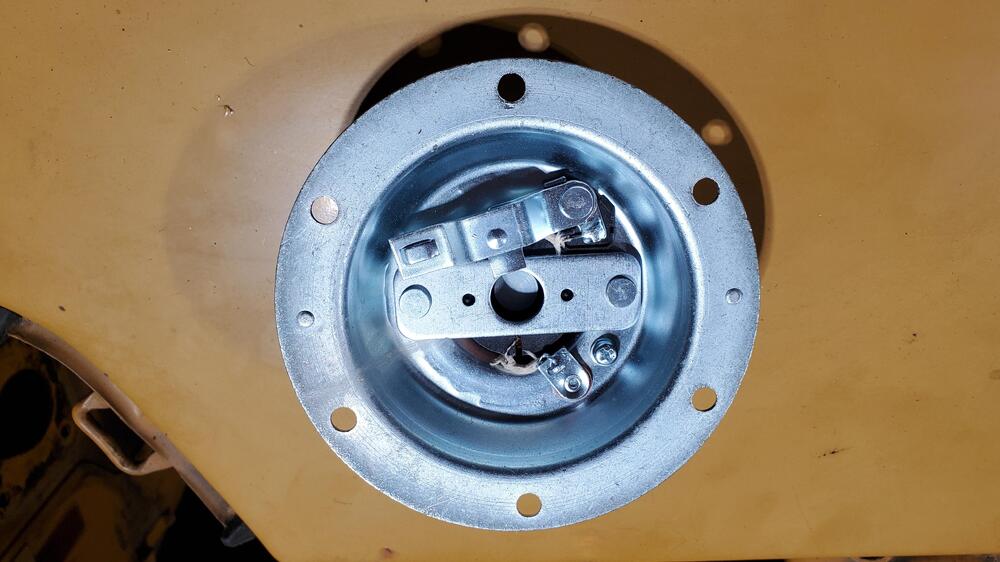

The length of the strut housing, the length of the thread, the strange upper mounts, and most obviously the brake caliper / brake dust protection shield mounts are completely different. Also, the mystery set got an integrated switch to adjust some settings.

Lower = mystery, Upper = 240Z:

Since the mystery set is quite incomplete (it only came with one spring, some of the adjustment rings seem not to be original, etc). I think the best I can make out of it is to keep the original adjustment rings from the mystery set as spares for my original set. The smaller, lower adjustment rings have a strange size of 101mm. That shiny one, which seemed to be an aftermarket / homemade item, had a diameter of 100mm, while all original Nissan ones had 101mm.

So I'm very happy now to have a complete set, even though from two different manufacturers, but that doesn't really matter, as it's only a small stamp on the strut housing which is different. I will yet have to figure out how I can restore them back to factory, especially the strut inserts might be tricky to find a good solution, but it's definitely doable and definitely worth to bring back this set to former glory. A big hat-tip goes out to Alan for all the Inputs and the nice photos. Your knowledge is of huge value to me, a and I owe you at least a gin-tonic next time we sit at a bar again!

Subscriber

Subscriber 3Points2,236Posts

3Points2,236Posts Subscriber

Subscriber 3Points11,184Posts

3Points11,184Posts