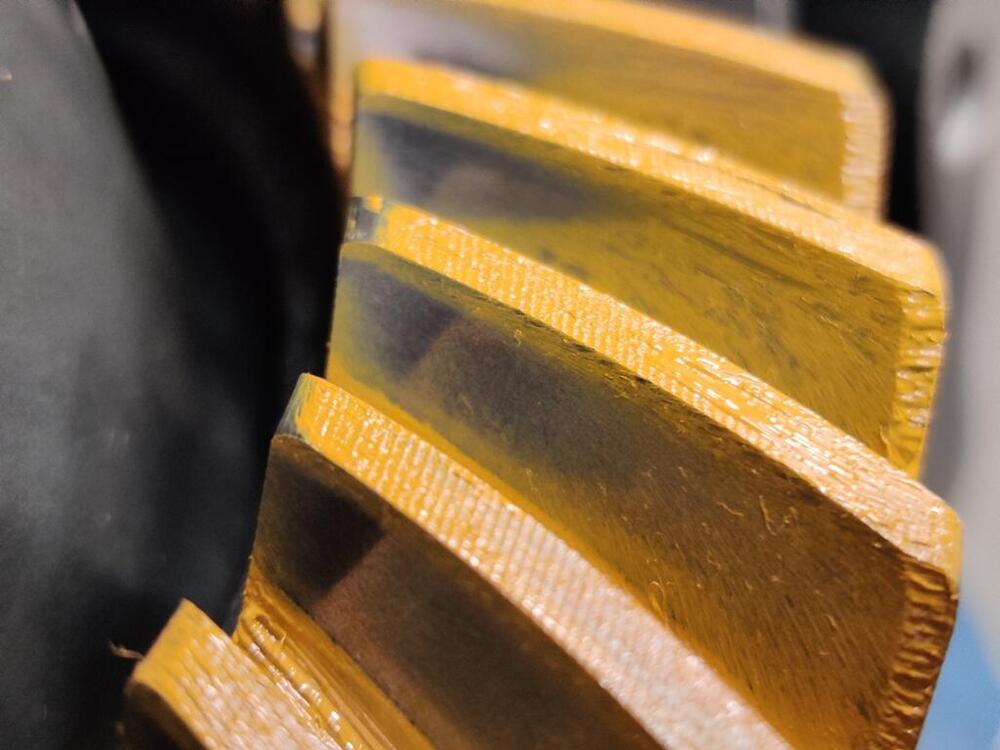

I was measuring runout incorrectly. I was measuring on the outside, angled edge of the crown gear. When I measured the backside of the gear, I got less than the .0031" factory specification. So, here are the wipe pattern pics:

Drive side - first pic is directly painted teeth, second pic is the paint transfer to clean teeth.

What I see here is that the contact area is nearly centered both from a top and bottom of the tooth and toe and heel of the tooth. The total surface area of the exposed metal (exposed by paint displacement) is much greater than my prior efforts where I was changing the pinion shim thickness. Paint is still present on the tooth surface above and below the exposed metal... and on the toe and heel of the tooth as well. This looks very good to me.

Shifting now to the coast side of the gear:

This is not as ideal. The exposed metal is mostly on the toe side of the tooth. It almost runs off the toe edge. However, I see a little bit of paint on the toe edge. And the surface area of exposed metal is quite wide and centered top to bottom on the tooth. I'd like to see the exposed metal area shifted more toward the center (with reference to the toe and heel) of the tooth.

Looking now at teeth that were not painted:

The pics above show paint that was transferred from the pinion gear to "clean" teeth. In these pictures it looks like the contact area is a bit more extensive. The width of the contact from top to bottom of the tooth is quite large. And the exposed area of contact appears to cover about 1/2" of the tooth between the toe and heel, mostly on the toe side.

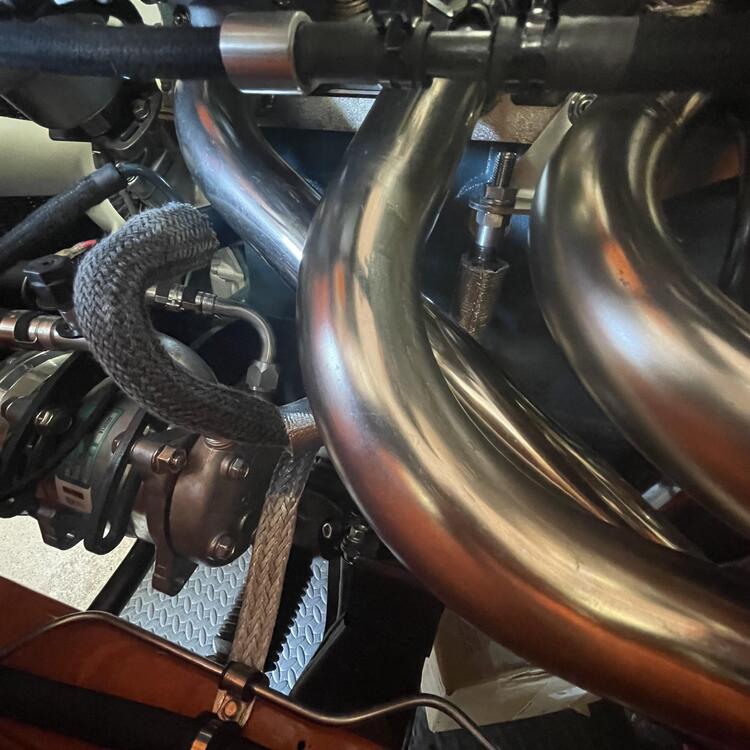

I am happy with the results I have achieved here. So, I will proceed with installing the oil seals and installing it in the car. It will be interesting to see how much noise this differential makes. From when I had it installed previously, I recall it made a low but noticeable amount of noise on deceleration, but it was quiet when under load. I had a 3.9 in the same car for a bit and it was incredibly quiet. I sold that one some time ago though as it wasn't the ratio that I needed.

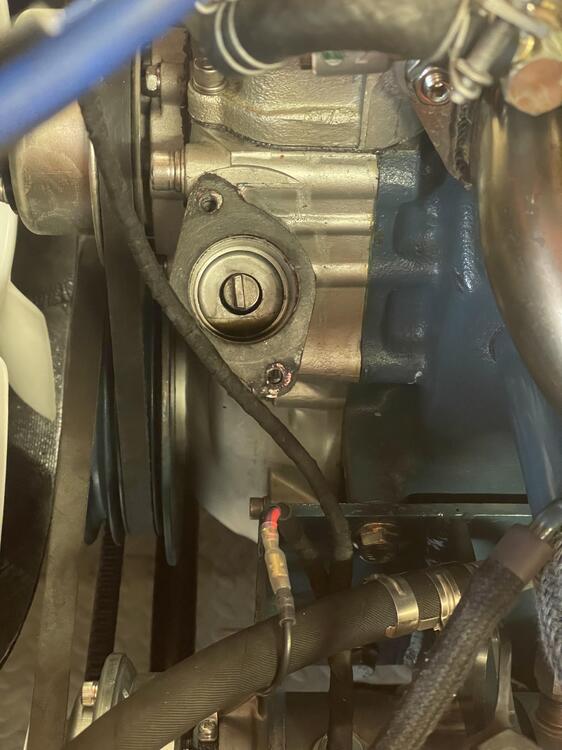

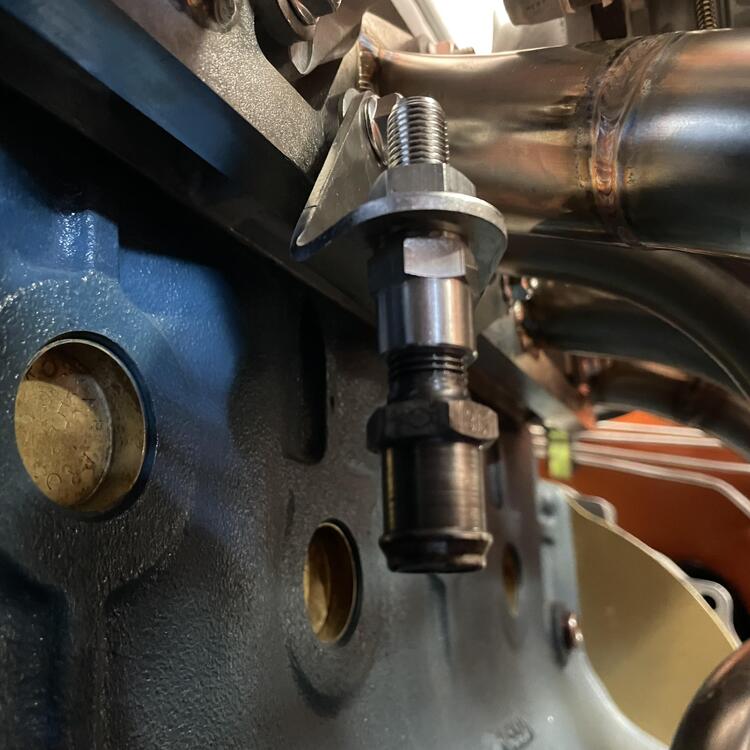

Net/net (summarizing this thread), I have installed the Quaife LSD carrier. I have replaced all of the bearings in the differential. I have reused the existing pinion shim and pinion spacer. In order to get the backlash within specification, I had to get the left side bearing retainer turned in a lathe to remove .5 mm of material, so that the retainer could recess that amount more inside the left side of the differential (when differential is viewed from the back). The .5 mm (about .020") which was removed was "replaced" with shims. I added back a .3 mm (.1181") shim to the left side bearing retainer, and put a .2 mm (.00787") on the right side bearing retainer with the rest of the shim stack there.

It would seem that replacing bearings on the pinion with new ones was actually "no big deal" with regard to changes to the pinion and ring gear meshing. Swapping in the Quaife carrier caused the ring gear to move away from the pinion gear vs. the stock carrier. Also, replacing the side bearings in the side retainers did not appear to change the relationship of the carrier to the case either. I am confident in this because I checked the bearing preload on the side bearings at one point - the pinion gear was not installed, and I installed the carrier and checked rotation of the carrier. My check wasn't measured with tools, but by hand; however, the preload "felt" noticeable, but not "heavy".

Anyway, I think I landed in a good place. I will be able to test that out now when I install the differential.