OK don't hate me, but cheapo ebay one for £129GBP - had other UK club members have good experiences with them so for the price it was worth a try as the original 2 row rad had started weeping.

https://www.ebay.co.uk/itm/394847457594 (Price has gone up since I bought it, but not by much)

Two of the 4 holes didn't quite line up so I had to gently modify them on the rad to fit.

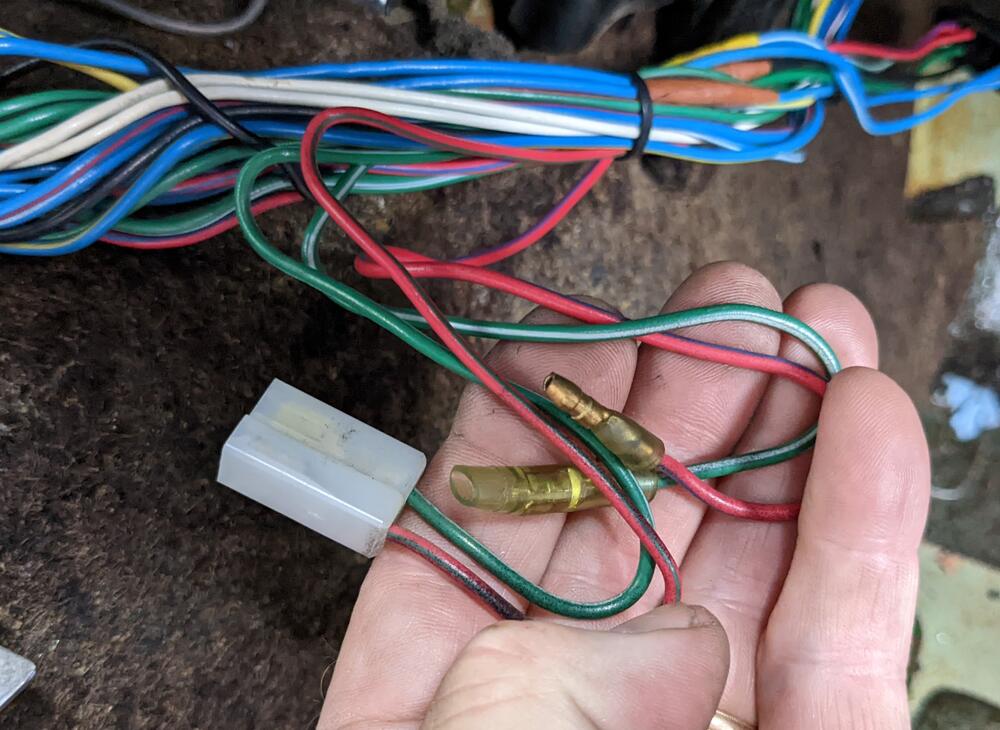

The fan shroud is a standard one, but again, I had to modify the mounting points for it to fit. In fact, I drilled and tapped the tabs where the shroud hangs so that I could screw the shroud on at those points. I'll log on from my phone in a moment and upload some photos.

As with any job on the Z, the moment you take something off, you have a) better access to something else to deal with, find surface rust to treat, c) start re-doing all sorts of other stuff and before you know it your 1 hour job turned into 9.5 hours!

So I gave it a quick test in the driveway with a 10 mins fast idle at 2.5K rpm with ambient temps of somewhere between 20-25 degrees C and bonnet shut. With mech fan only, the temps only went ever so slightly over halfway.

Proper test run this weekend once I re-wrap the loom I unwrapped to do neatly (because that was vital to my cooling project, right?).

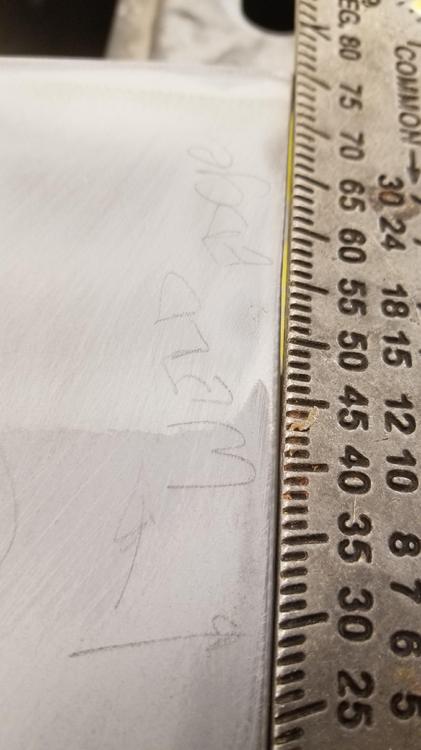

Hole mods - see sharpie marking before I drilled / filed it.

Modifying rad and fan shroud

Had to protect the fins during install as they are more delicate than the copper / Nickel ones on the original rad

Subscriber

Subscriber 4Points11,142Posts

4Points11,142Posts