Thanks, I found some relevant posts. One of the frequenters of that site said, "It's been my experience that the backlash doesn't change notably. It changed .0005" on my own diff, and I've never come across any posts from someone whose backlash needed to be readjusted after installing the LSD."

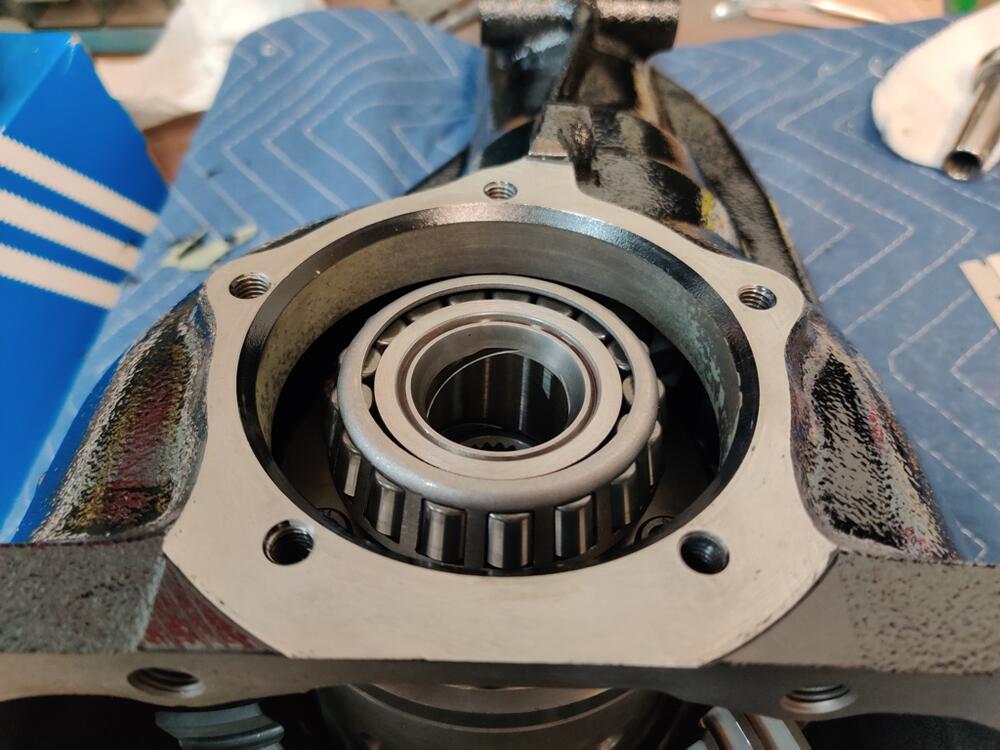

Before disassembling to remove the paint from under the side retainers, I measured the back lash, and it was about .014". The factory spec is roughly .004" - .008" (the factory service manual is not near me right now). I then removed the side retainers and scraped off the paint with a razor blade, and reassembled. After doing so, I put the side retainers back on, snugged the 5 retaining bolts, and measured back lash at .020". That was surprising to me, but I figured maybe I didn't measure it properly the first time.

The factory workshop manual says that if there is too much back lash, to move shims from the left retainer to the right retainer. As assembled from the factory, the left retainer has one shim that I measured at .011" thick. The right retainer has two shims, one is .016" and one is .020". So, I took the side retainers off again and moved the shim from the left, and stacked all three on the right. I reassembled and measured back lash at .012-.013".

Darn it.

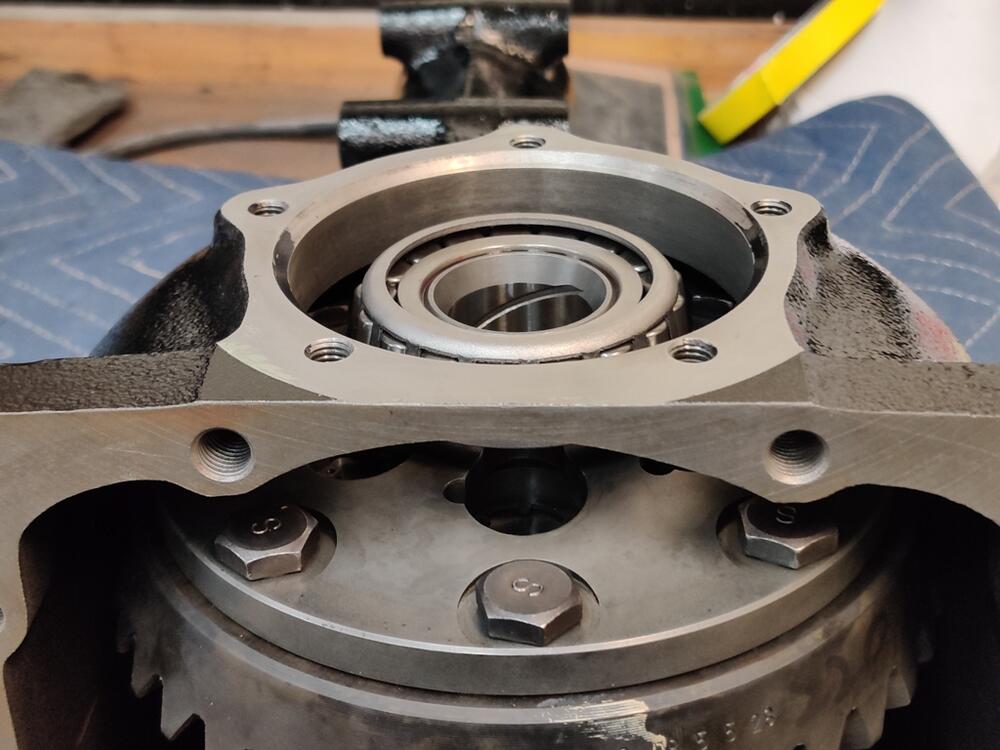

I found several pages back in this build thread, where I measured backlash before disassembling this diff, and it was .005". So, referencing the info from the Hybrid Z post, I appear to be in an unusual situation where swapping out the open carrier for an LSD has perhaps changed things substantially. Of course, in this instance I changed pinion bearings, so perhaps the pinion height has been altered now.

As a next step, I will measure the turning resistance on the pinion shaft to rule out that I over torqued the pinion nut and have too much pinion bearing preload. I ordered a torque wrench which should allow me to check that properly - it will be here Monday. However, I don't have much hope that the amount of preload on the pinion bearings is my problem.

Doing something other than using the shims that came with the differential is a departure into the wilderness - this is not something I have ever done before. So, I really am feeling lost about how to get this diff set up properly at this point.