Today i got a long-awaited delivery from Japan.

it constisted of three parts:

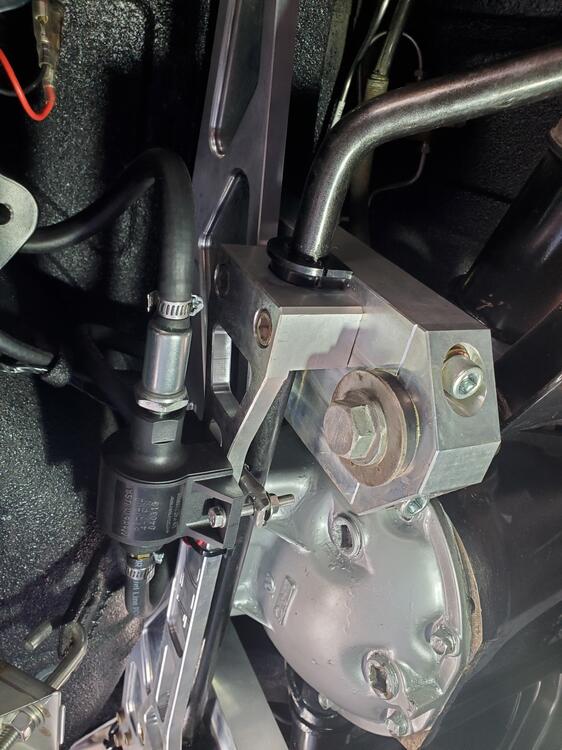

1) An OEM Adjustable factory competition suspension by KYB.

I still need to investigate a bit. I'm not even 100% sure if this was intended for this specific version of car, and i know there were many different versions of adjustable suspension around.

Especially this part (I assume it's to adjust the push / pull pressure rate?), ius not seen on all of these adjustable suspensions.

As you can see it's not in the best, but restorable condition and one spring is missing, so i got it quite cheap. that's the reason i bought it. Mainly to investigate further and figure out the details.

Here a quick reference (top: Adjustable / bottom factory Euro spec 240Z):

Meanwhile i was even able to buy a second (complete and better condition) set, which is still in japan and will take another few months to arrive here. but yeah, it will definitely give me further insights. I will definitely need to find some time to find out more and will share the details with you.

Here is a reference picture from the Competition / Sports option catalogue:

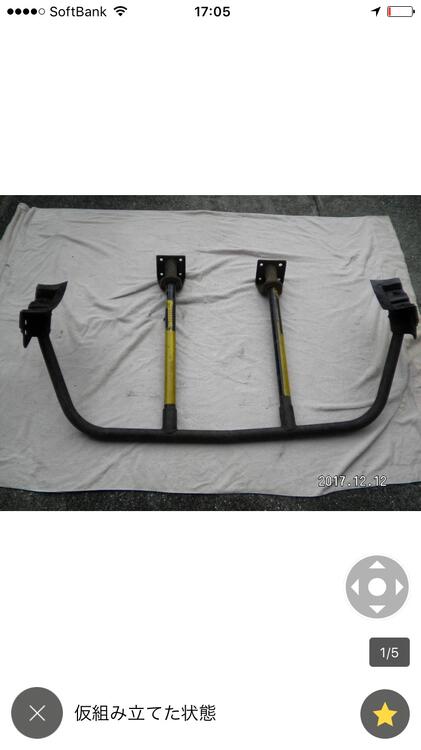

2) The second item i got is an OEM Sports Option / Competition rollbar replica by Mizukami Auto (JP). According to mizukami it is an 1:1 Copy of an OEM rollbar they have in their shop, but with some improvements to simplify installation and fitment. I think the main difference are the mounting plates on the wheel arches.

.

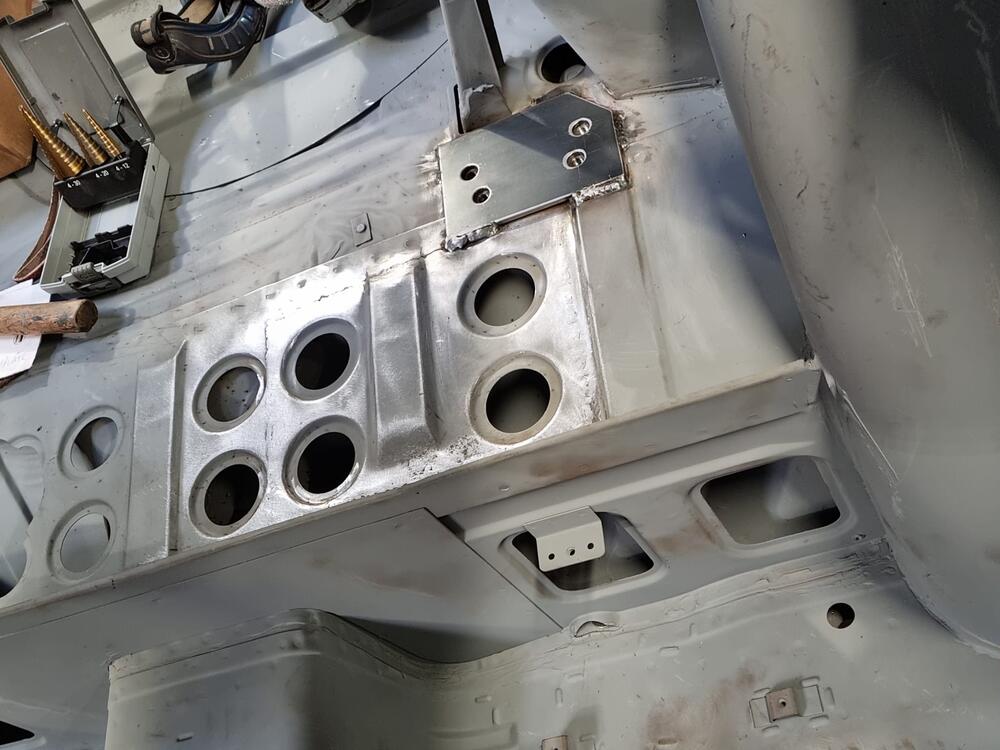

Which seem somehow pre-assembled (welded) vs the single screwed-together puzzle-pieces you get from an OEM bar, but otherwise seems to be a quite similar design. What is not visible in my photo is a separate lower plate on the wheel-arch mounts, since they are screwed to the mount sin the picture. but they are detachable, just like the original ones. Since an OEM bar is almost impossible (and expensive) to find these days, i thought this would be the next-best option.

I have to say the quality is really high and it looks pretty good and the single pieces are quite complex, which justifies the not-so-cheap pricing. Unfortunately i don't have a chassis in-house at the moment to test fit it.

So the next best thing was this cheap mock-up. and i probably even did it the wrong way around without the car as a reference... Nevertheless, it looks good.

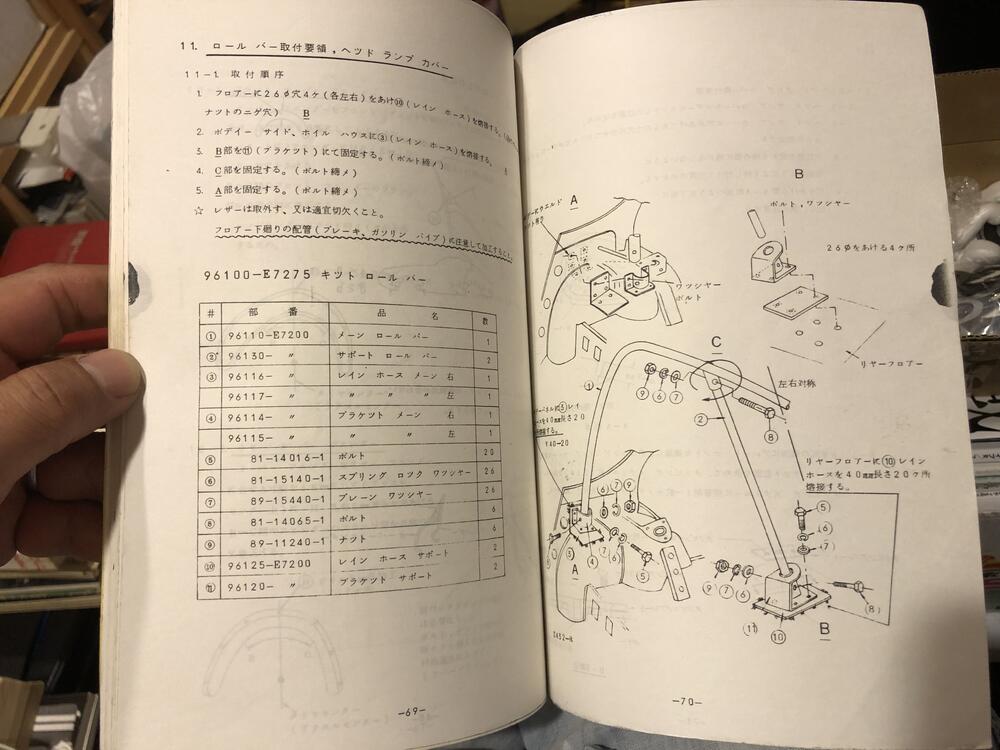

Here's a reference from the JP Competition / Sports option catalogue (see single plates at the bottom left and right).

And here's an installation guide from the Race and rallye preparation manual. From what i understand, every OEM Z should have the installation points prepared in the chassis to install this, but again i was not able to verify this without the car on site at the moment.

3) OK and last but not least i also got this drian plug from Mizukami auto. I mean it would be a shame to not add some small gimmicks when placing a big order, right?

Despite a few questionsmarks i think the suspension is quite rare and cool and useful and the rollcage definitely better then the Saito full rollcage i had originally purchased many years ago. Also in terms of registration as a historic car and the general MOT in switzerland.

More updates on the suspension topic will definitely come soon and i will also try to test-fit the rollbar as soon as possible.

Subscriber

Subscriber 5Points11,142Posts

5Points11,142Posts