It has evolved some, and now it consists of:

Using these glass beads from Northern Tool and Equipment, important for size of grain, and bead blasting at 90 psi with a 1/8th inch nozzle to remove all rust, and to establish a consistent finish. I use one of these baskets and find that putting a variety of hardware (big and small) is great for trapping the parts in place so I can blast them without them flying around too much. For large parts, you don't need to use the basket, and you can then go back over them with the pressure at 50 psi to put a smoother, easier to "second stage prep" by hand, finish.

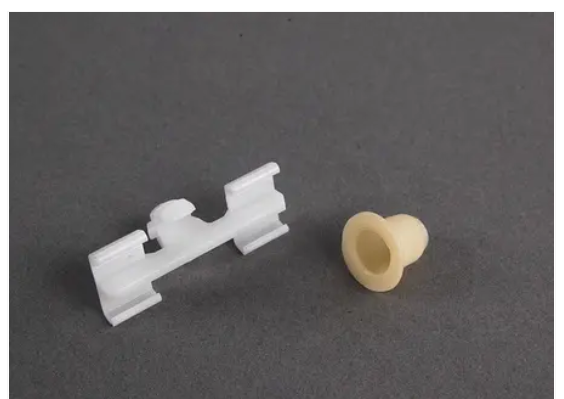

For all hardware (bolts, washers, nuts, screws and odd small bits), I go straight from glass bead blasting to tumbling in one of these vibratory tumblers. I now use a stainless steel media (bought from Southern Shine Tumblers on Facebook). See pic below. It consists of tiny little bits of stainless steel that are good at getting into tight spaces, like between threads, phillips head recesses, etc. And now I use it dry. I was using water and a bit of citric acid, but I think that is best for doing brass shell casings. I was fighting keeping the parts from starting to oxidize/rust, and have found that the media works better and faster dry... to put a nice finish on the hardware. Time in the tumbler is about 2-3 hours.

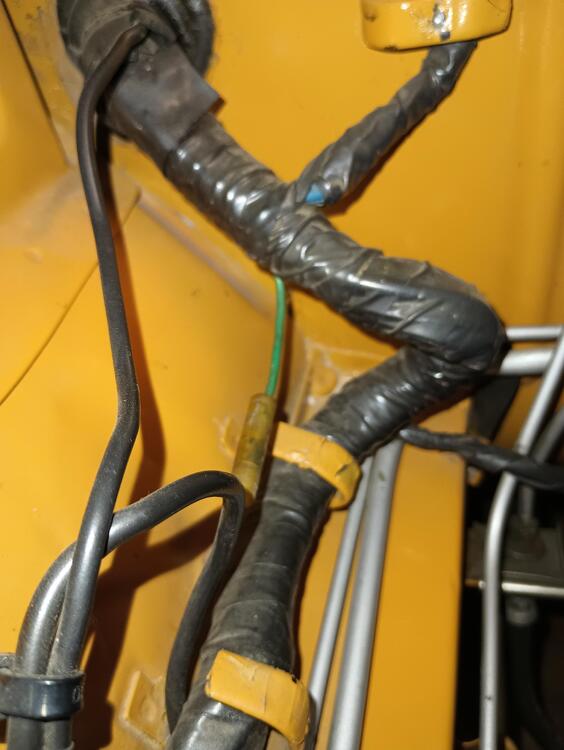

For large parts that I can't tumble, I use a Dremel tool and the little wire wheel brush attachments after glass bead blasting. For final, more consistent finish, I follow wire brushing by hand rub the large parts with #0000 fine steel wool. Doesn't take a lot of work by hand, but the combination of using the Dremel followed by fine steel wool by hand does end up taking some time.

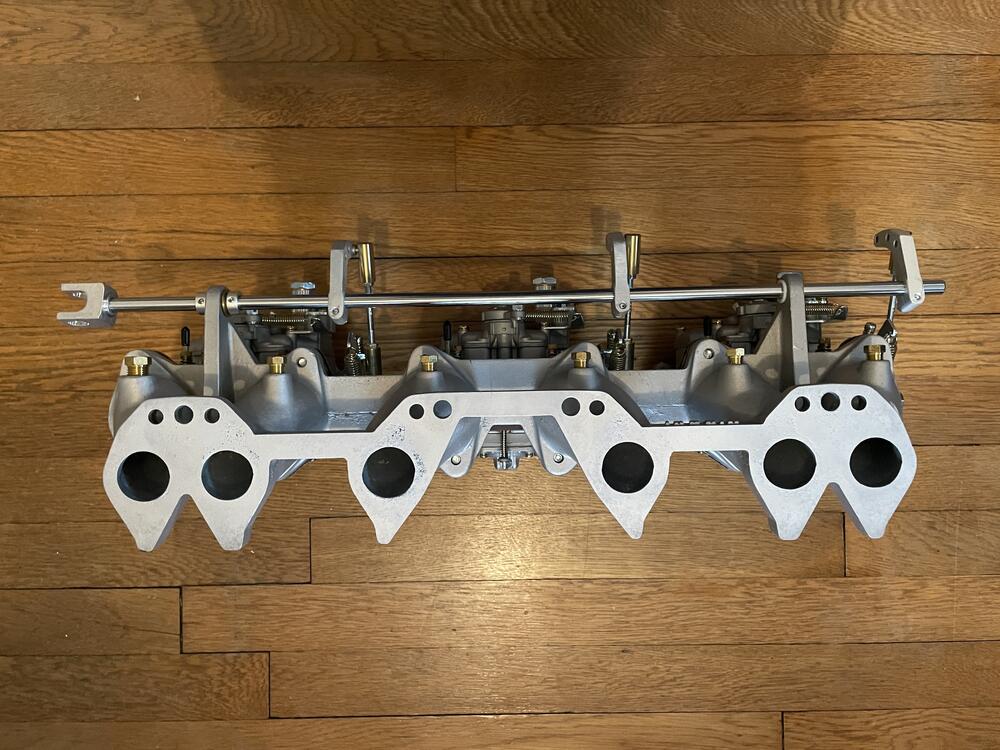

The glass bead finish can be altered on aluminum parts, by the way. It can look really nice, if after going over it once with 90 psi, you lower the pressure and go over the part slowly. Extending the distance from the gun tip to the part also smooths out the finish, giving it a nice satin look. I am still experimenting, with some aluminum parts, but a once over with 90 psi to clean followed by a once over with 50 psi achieves a really nice finish.

Subscriber

Subscriber 7Points428Posts

7Points428Posts Subscriber

Subscriber 4Points1,282Posts

4Points1,282Posts