I set up for blasting parts on Saturday. It was sunny and cool, great weather for blasting. When I was using play sand, my blue tarp caught like 90% of it. Switching over and using Black Diamond (coal slag product) for the first time, I noticed two things. It is much more aggressive than play sand - Haha! And, it travels a greater distance, so my tarp wasn't catching it all.

As I said previously, the plan was to blast and prime and paint all the parts from that long list at once. Right... good one. The best laid plans...

I made good progress though, running through and refilling the pressure blaster 5 times over the span of about 5 hours. So, now I have switched to doing blasting on weekend days as weather permits, and priming and painting in the evenings.

The black diamond leaves quite a texture on the parts:

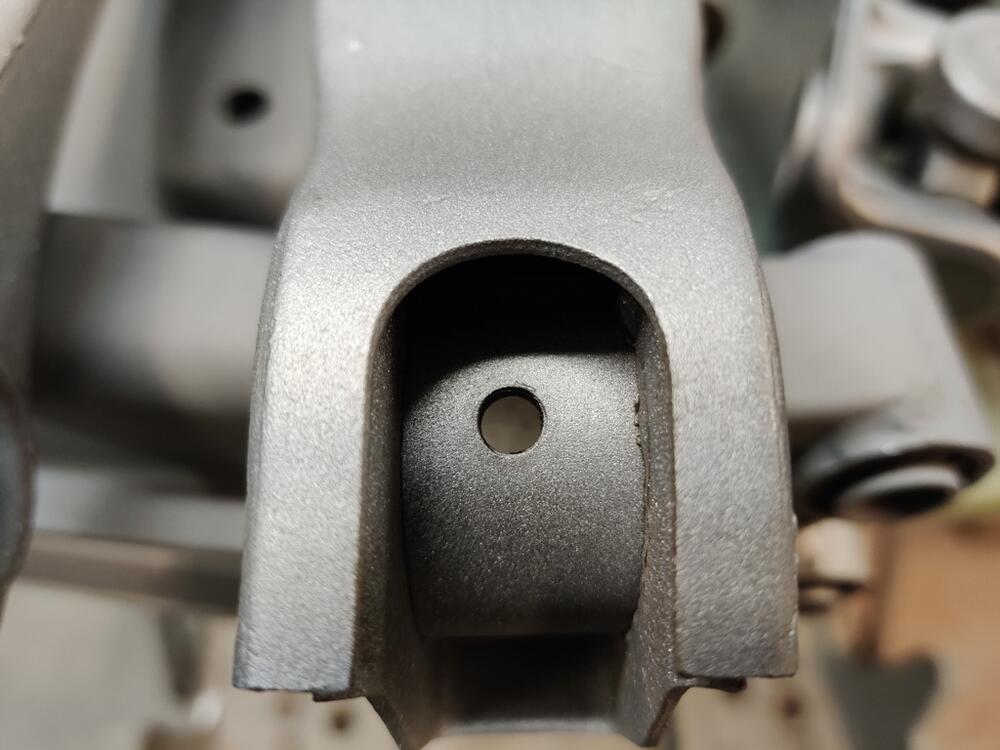

Stripping of paint and surface rust is quicker, but I didn't want to leave the texture this rough. So, I am taking each piece and running it through my glass bead cabinet to smooth out the roughness:

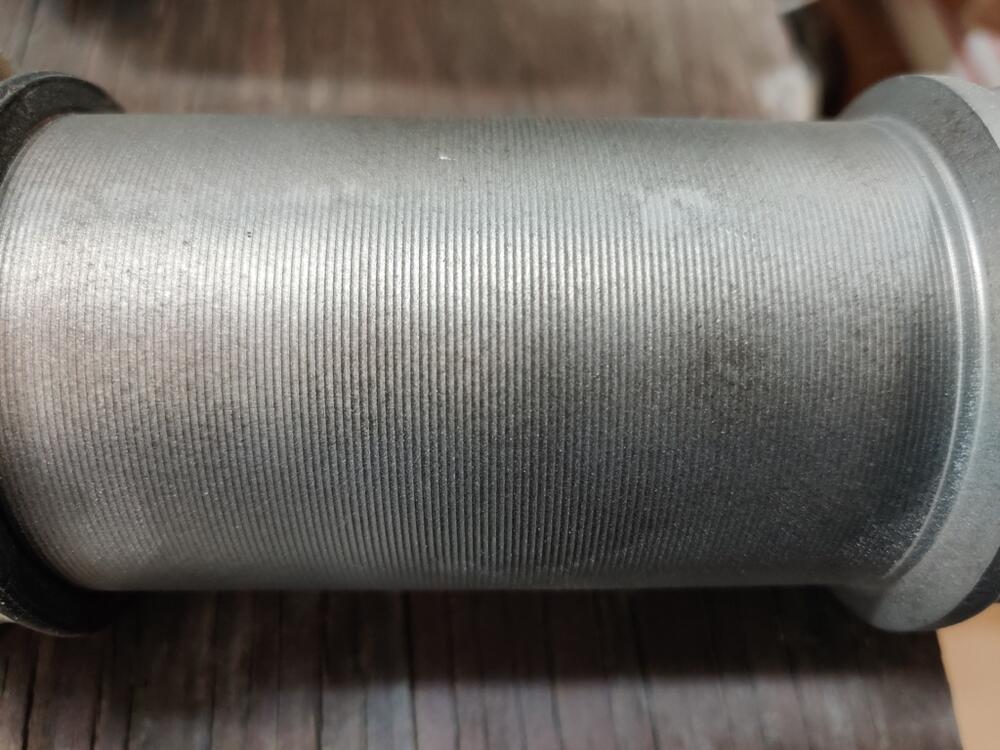

Driveshaft u-joints appear to be original and feel like they are in great condition:

So, instead of all at once, I have a few phases of "production" - some parts still to strip, some stripped bare, some epoxy primed and waiting for minor filling of scrapes and nicks, and some painted black:

We'll see what the weather and this weekend allows.