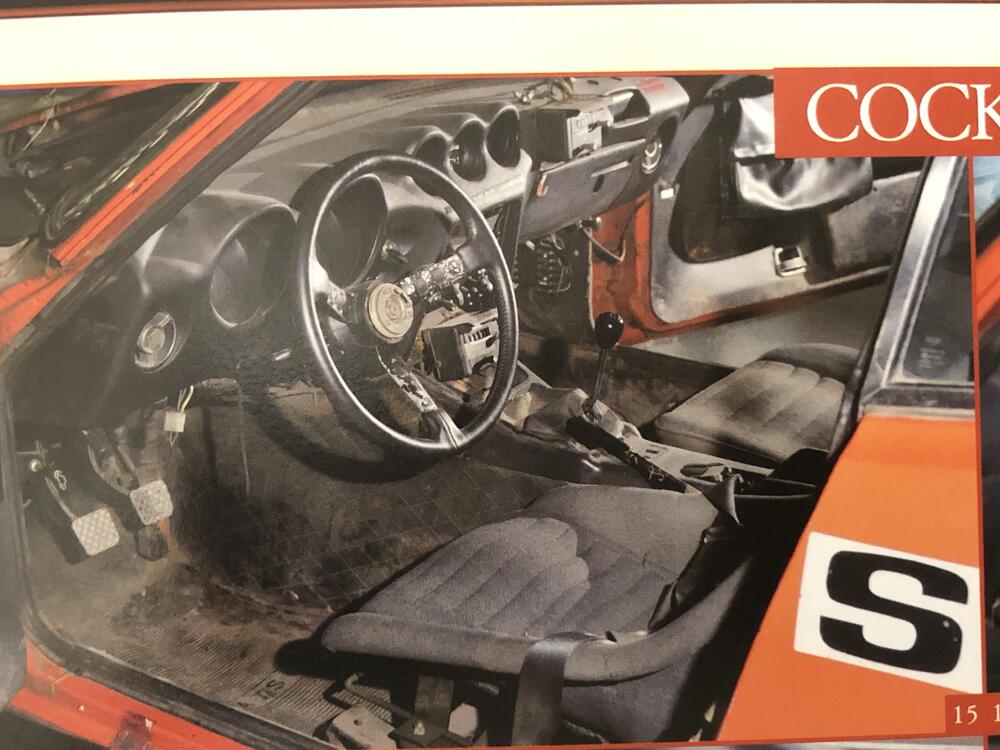

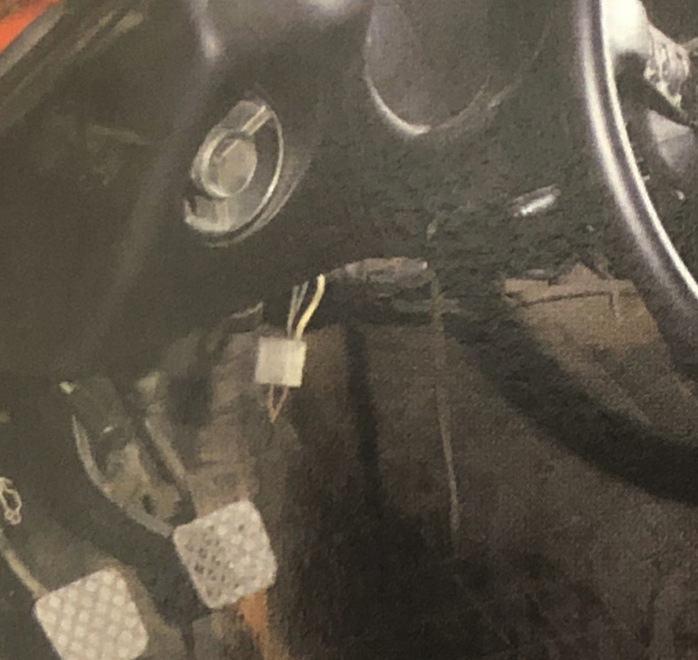

Something else caught my eye in @kats photos, namely this dangling 6-point plug (pictured), presumably taped to the steering column of the '73 car. I'd imagine it's designed to plug into the ignition switch in place of the standard harness, and potentially make the car drivable in "hobble" mode, or at the very least, to bypass some of the wiring in order to debug something engine-related. I also had one of these in my car, taped in the same location, with a bare-bones collection of stand-alone wires leading to the fuel pumps, and I believe the starter and alternator (and perhaps more - I'll have to reconstruct my notes). I was fairly certain at the time I removed it that this was something wired up by a prior owner, and not original Works, based on what appeared to me as haphazard wiring. Seeing this dangling plug in the same spot on the 73 car makes me question my original assessment. I've often heard "dual wiring harness" being used in descriptions of Works cars, but I always assumed that people were referring to the 2 fuse boxes, and not the presence of a "redundant wiring harness". More study will be required- any further thoughts?

.thumb.jpg.f8433a3aae5a8a619fe5d5ed3e4686b3.jpg)

.thumb.jpg.1e439d64a65ca0edf5784c1389b1b2be.jpg)

.thumb.jpg.ffd23c9a7bdd6617365b0fc1cf981b55.jpg)

.thumb.jpeg.7df39b24242470b71f0d44c7d6b6de5b.jpeg)

.jpeg.b3706c0baaed5e9786607590fe807480.jpeg)

.thumb.jpeg.6d2d2631222c0b0be064802e4838aebb.jpeg)

.thumb.jpeg.bb5cbac2c279b7249588858ed44c5e7c.jpeg)

.thumb.jpeg.6c9fdb4cc661c9c74559be8f6e6817a0.jpeg)

.jpeg.935189d94426d8dfa134611f7438a1bd.jpeg)

.jpeg.a621cf45fd4a582f3e773eb09b95864a.jpeg)

.jpeg.ceb750a92c4941d01c1bc35a30b83849.jpeg)

.thumb.jpeg.595fe08f43512a98282a187a7642b630.jpeg)

.thumb.jpeg.fddc1cb6dfba220be86516bae87bbe62.jpeg)

.thumb.jpeg.ceb63612fd97dfbcc9e0b08daafe31d3.jpeg)

.thumb.jpeg.dfe4a229dd8dd8509650c9f6ac810c23.jpeg)

.thumb.jpeg.e3b3da943ecff1ad59378bcb36b926bf.jpeg)

.jpeg.bea2f8f758d8513bd8ccbb2e16f4bf13.jpeg)

.jpeg.a4a182ef840388f8ddecff2f6c1ffaa9.jpeg)

.jpeg.a6a6c720f6d6d406cdd39712a7edcb55.jpeg)

.jpeg.656718b7887d3b91af4b4051eabc2589.jpeg)

.jpeg.512b8e358a0eac553d381e8844163cb2.jpeg)

.jpeg.e46feff5c49176847680a61264b9613b.jpeg)

.jpeg.99bbea32e7b636fd492f46f90aa96d66.jpeg)

.jpeg.833238e31ec1da201834606ce707a2e8.jpeg)

.jpeg.644dfd1ca1d191fd6d4b4a80b6bc0f55.jpeg)

.thumb.jpeg.e5942755927e5a37ff5c5da3a26fb54e.jpeg)

.jpeg.dc71a1e1998b857c496fe95f802c84d3.jpeg)

.jpeg.40892db3dd84c432021e7c84f01e447c.jpeg)

.jpeg.a29521d0bce8b5878aa93534a74c99a4.jpeg)

.thumb.jpeg.a3b224594c88b48e82370175f49c100e.jpeg)