70zfun,

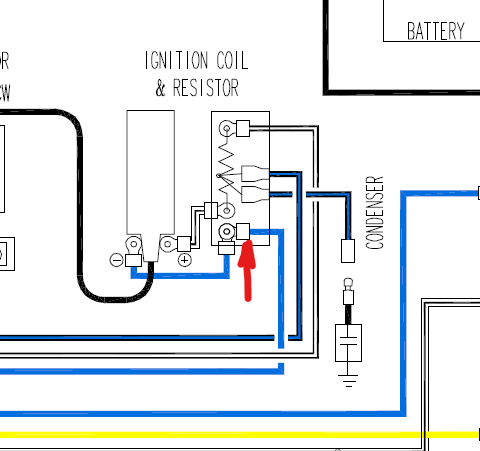

Reading your post made me recall my experience last year with a similar engine "miss" at high speed and high load. My engine is the original L24 rebuilt 3 years ago with Ztherapy carbs, Pertronix II, and 0.6 Ohm Pertronix coil (ballast resistor bypassed). I may be running a bit more advance than you as I have 35 degrees total (static + centrifugal) at 2800 rpm. At full throttle in 3rd going uphill merging onto a limited access highway I would get a miss that would not let it rev above 5000, it did not backfire but just wouldn't pull. Never noticed anything in 1st or 2nd gear. Everything on the engine was new or in the case of the carbs, rebuilt. The problem was resolved with new set of NGK spark plug wires. It turned out that the wire to the number one cylinder on the other wire set was defective. As a test, this morning it revved to 6000+ with no issues.

I think you are on the right track, set the valves, timing, and perform a general tune up to see if there is any improvement, if not, look at your coil and wires.

.thumb.jpg.4f54021f7cd56e62dbb0a919d36f2306.jpg)