Since there is still a lot of stuff about these not known exactly and many confusing topics, thousand of pages and myths, I will try here to make it easier. If anyone has additional information or something is not right, please post, then I will modify the 1 post.

This is for stock factory transmissions only, NOT competition ones.

There are A, B and C types transmissions ( C was never used in Z cars so I will not add these here )

Update 9/7-21 : Also the 4.11 ratio R180 was not used on Z cars ( correct me if I am wrong )

Also not sure if 3.90 was used in the USA on the 260/280Z and ZX

So far I have:

Nissan S30 Fairlady Z Japan till 1978:

F4W71A manual

F4W71B manual

FS5C71A manual

FS5C71B manual

3 speed automatic 3N71A

3 speed automatic 3N71B

R180 Differential, possible gear ratios available: 3.36 / 3.54 / 3.90

240Z:

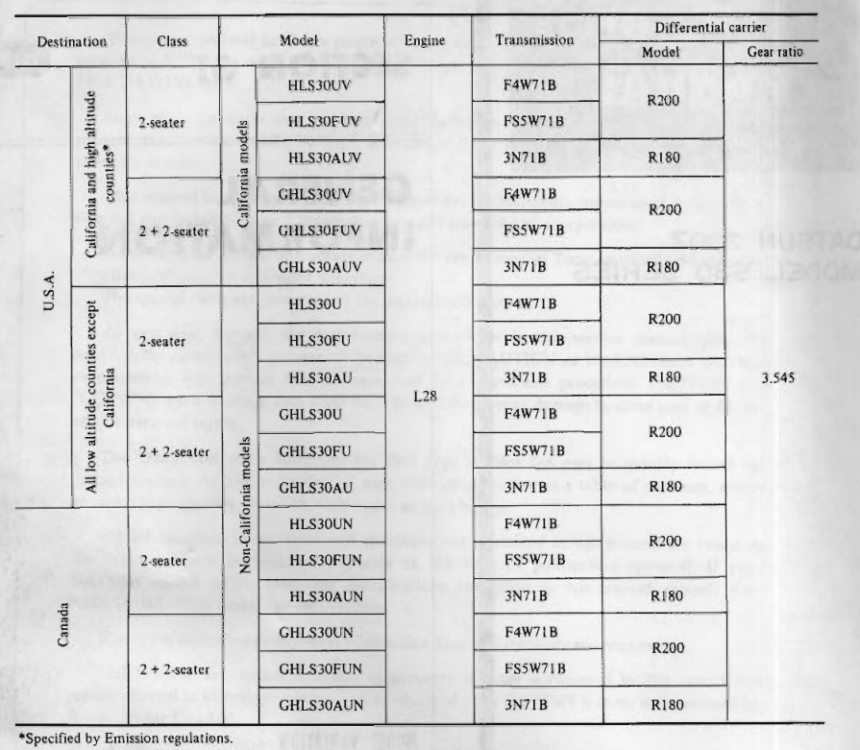

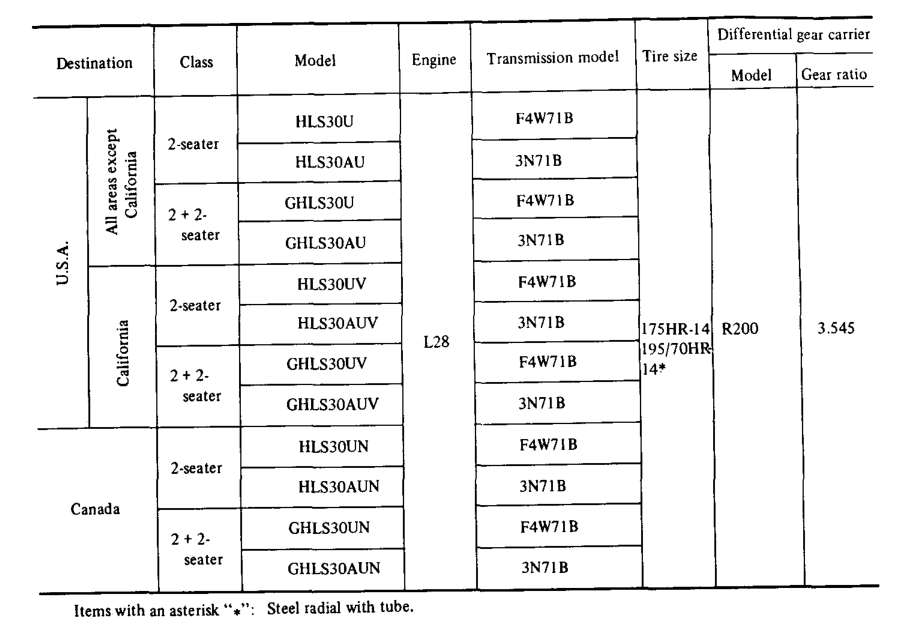

Datsun 240Z USA and Canada

F4W71A manual

F4W71B manual

3 speed automatic 3N71A

3 speed automatic 3N71B

R180 Differential, possible gear ratios available: 3.36 / 3.54

Datsun 240Z Europe, UK, rest of the world

FS5C71A manual

FS5C71B manual

3 speed automatic 3N71A

3 speed automatic 3N71B

R180 Differential, possible gear ratios available: 3.54 / 3.90

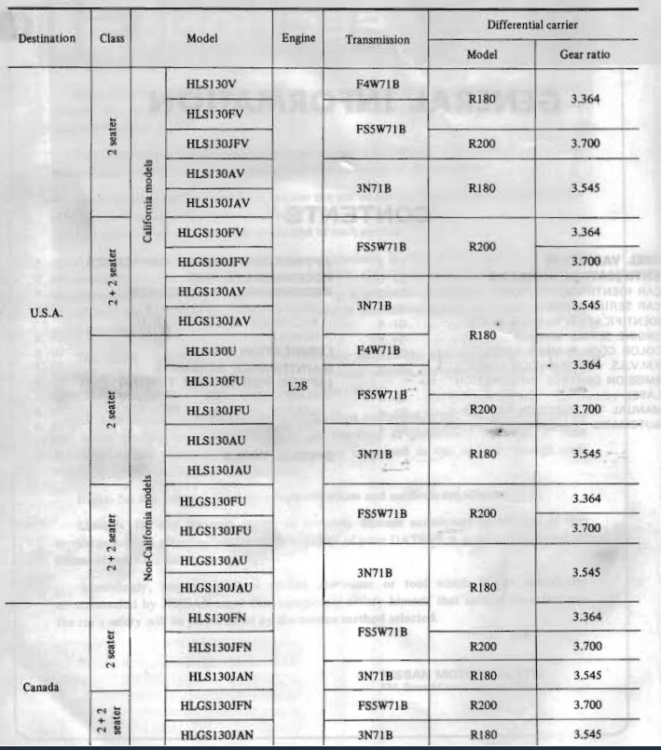

260Z:

Datsun 260Z USA and Canada

F4W71B manual

FS5W71B manual

3 speed automatic 3N71B

R180 Differential, possible gear ratios available: 3.36 / 3.54 / 3.90

Datsun 260Z Europe, UK, rest of the world

FS5C71B manual

3 speed automatic 3N71B

R180/R200 Differential, possible gear ratios available: 3.54 / 3.90

280Z:

Datsun 280Z USA and Canada

F4W71B manual

FS5W71B manual

3 speed automatic 3N71B

R180/R200 Differential, possible gear ratios available: 3.36 / 3.54 / 3.70 / 3.90

----- ------ ----- ------ ----- -----

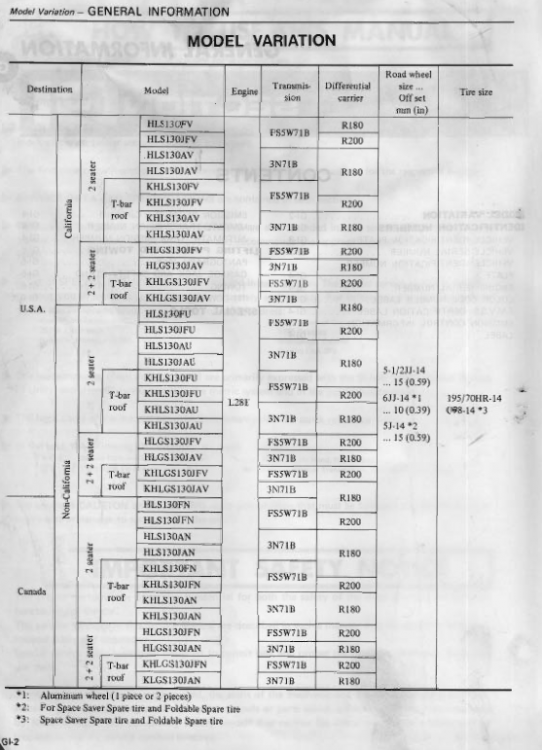

280ZX:

Datsun 280ZX USA and Canada

F4W71B manual

FS5W71B manual

5 speed Borg Warner T5

3 speed automatic Jatco 3N71B

R180/R200 Differential, possible gear ratios available: 3.36 / 3.54 / 3.90

Datsun 280ZX Europe,UK, rest of the world

FS5W71B manual

5 speed Borg Warner T5

3 speed automatic Jatco 3N71B

R180/R200 Differential, possible gear ratios available: 3.54 / 3.70 / 3.90

Nissan S130 Fairlady Z Japan:

FS5W71B manual

5 speed Borg Warner T5

3 speed automatic Jatco 3N71B

R180/R200 Differential, possible gear ratios available: 3.54 / 3.70 / 3.90

Subscriber

Subscriber 5Points11,142Posts

5Points11,142Posts