I didn't have any problem with M-Speed Japan having wheels made and selling them to the general public, as they were good quality and a fair price for ex-Japan sales. I recommended the M-Speed reproductions to several people, and several friends of mine bought them and are happy with them. So, no problem at all with M-Speed product.

So, you have approved the Chinese factory wheels and it's hardly surprising that you and your friends thought them a ‘fair’* price compared to Made in Japan JDM wheel prices as these wheel manufacturing costs were so much less.**

Negative, or just willing to call you out? I'll put that down as both a 'cannot' and a 'will not'.

You can put that down as ‘CBA’, Alan but I answered your questions in the Z432 thread and copy them here for your information :

These wheels are of the same quality as those offered for sale by M-Speed so I don't need to have visited the factory to satisfy myself of their build quality and metal content - please stop scaremondering the public - it's is irresponsable and you place a doubt on anything 'made in China - THAT is what our initial discussion was on the subject of these wheels - your consistently blinkered belief that anything made outside of Japan is of an inferior quality for 'our' Zs !

Since you haven't answered my above questions, it's hard to come to any conclusions. . If M-Speed Japan have green-lighted sales direct from the Chinese factory for some reason (there could be any number of reasons).

You don't answer any of mine so try to reach those conclusions - you’re a smart man but I'll help you out again - M-Speed aren't selling enough for the factory to make money....now, why aren't they selling enough and before I came along.....? The product excitation has long since died down after their apparition two years ago.

If they hadn't been out-sourced to a Chinese factory, they would probably never have existed if we accept the actuel price of them reflecting the real start-up investment ; making them elsewhere made them possible. But again you are guessing, surmising as to how much are the costs ! I know because I've paid for the molds of another wheel and I know the build costs of these current wheels. I'm no multi-national parts group, I could afford it !

Now the angle is 'piracy' ! But who (if anyone) is committing piracy here..........?

piracy : the unauthorized use or reproduction of another's work.

.......the buyer, the seller or the productor ? I bought these simply by contacting the factory and asking to buy them : "yessir, how many would you like - there is a MOQ (minimum-order-quantity)" ? Alan, no doubt correctly, states that these have been on sale for two years....plenty of time to have sold hundreds and recovered the start-up costs......but the wheels aren't selling (wonder why ?*) and the factory needs to produce and sell...that's how any factory makes money for it's owners and workers ! *M-Speed have set the marker price too high !!! Please stop manipulating the public.

Did M-Speed even have permission to copy a Nissan factory wheel ?

These wheels and those of M-Speed are not made in Japan, they are not genuine, period wheels - we all call them 'reproductions' but to all intents and purposes they're 'fakes' .

Knock-offs – the definition quoted from https://dictionary.cambridge.org/dictionary/english/knock-off : a cheap copy of a popular product

That sums up M-Speeds’ wheels and mine ! Or are we saying that so long as that cheap product is sold expensively, it’s rubber-stamped as ok ? We’re getting close here to the emperors’ clothes…..

In someone elses' world, $650 per wheel might be a ‘fair’ price but I’m just another reguler guy with kids in college and I'm offering them to reguler Z owners at an affordable price - $350 each upon which I’m making a ‘fair’ profit with which to reinvest.

This company doesn't sell these for free, they're getting their cut out of the M-Speed profit margin : https://jdm-car-parts.com/products/reproduction-fairlady-z432-magnesium-wheels-aluminum-wheel-sold-individually?variant=15222843539565

Perhaps it does come down to ethics : you either buy mine or you pay double the price, believing that 100% goes to help M-Speed......like sending money to African-aid charities where 5% of it finally reaches those that need it unless the local warlord or civil servant doesn't pocket that too !

1) I believe that every Z owner should have access to quality parts at affordable prices.

2) Alan, by attempting to place doubts on these wheels' quality, by stigmating anyone who touches them as a pirate and suggesting that you should pay double my price if you REALLY want them merely, IMO, highlights his wish to keep this 'look' to an exclusive 'club' of owners who can throw that sort of money at their cars - his reasons against my entreprise are solely driven by a selfish desire not to see the prolification of these wheels which, in his words, "is bad for all of us in the long run".

To show my good intentions and to support this forum, I will offer a us$60 reduction of the purchase of a set of these wheels to all supporting members.

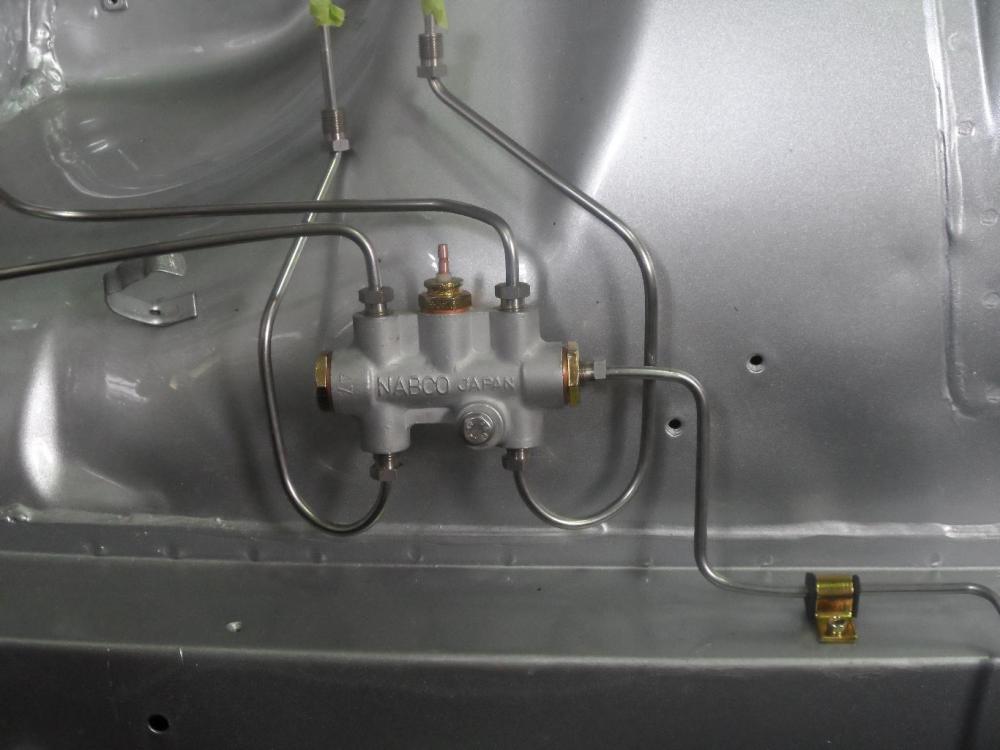

ps : proof that I know what it costs to make wheels !