Yes, install dizzy=use timing light. No question.

Although a year old thread, I do want to chime in here.

Since about the time this thread began, I have been running the (Bluetooth) 123ignition /Tune+ On a 260Z block / heads with twin SUs and SM needles. I also run a hotter coil (oil damped) Bosch Red is also ok. And I’ve bypassed my ballast resistor and rotor resistor myself. Why have extra resistance in your circuits, unless you still use AM radio? Heh, heh.

No problems with the engine / timing in over a year of spirited driving. I love to tune it as I choose each day, depending on how I plan to be driving. I have several Curves, like 10 including the ‘Default.123’. I use an ipad and also my iphone. You can tune ‘one the fly’ (just +/- advance, you can’t change or save the curve-yet...). SO City it’s start & stop, so use a good idle maybe 10-12d BTDC at 750rpm -not my default map which as lower idle advance. Cruising the freeway or touring (I want better milage), twisty mountain canyons (lots of advance at high rpm). It’s cool to have variable Timing / vacuum advance curves, without playing with advance weights, or adjusting the position of the dizzy manually to change static advance.

Some comments:

The setup procedure with the LED light is only good for getting the engine running with the new dizzy. Then run the 123ign centrifugal map with 0 degrees up to 1500rpm in the app and set the engine (with the timing light) to match. I read somewhere that using the LED procedure can actually set 5d TDC static to ‘get the engine started’ easily. I didn’t see this myself, but it brings up the next point. Personally I wouldn’t run the default map and LED timing except to test, and certainly not on the road and under load.

Do NOT set up static timing, it screws everything up, and you would have to ADD that to all the values 123ign “sees” in real time and when you add vacuum retard “maps” (which *will* kick in at 1500rpm by default) it gets way too confusing. That is IF you run a vacuum advance line / dizzy (I do)- most with triple DCOEs won’t (or can’t as there isn’t a common plenum). You confuse the123ign and more importantly yourself as to the advance you are running.

I did write to Ed Madak, before install and he was very helpful The instructions are incomplete and they expect you have some knowledge. He said:

“Hi Richard

Setting the app to 0 and the number one cylinder to TDC is preferred as it will show exactly what you have set your timing to.

Always confirm using a timing light and synchronize the app with the motor.

Hope this helps“

It did help. So you don’t think I’m a fanboy, here are some issues I have experienced and tried to solve:

1. The install instructions are terrible. Read the above and take note, hard lessons learned, you must confirm you have TDC marked correctly on your harmonic balancer. Then use a good timing light, one with dialback if you can. I even made an ‘newbie’s guide’ (ymmv) of my 123ign install & posted it on YouTube:

2. These engines love advance, but personally I don’t exceed 35d advance even at 8000rpm (it’s never driven as a race-car). I also usually RPM limit at 7500, 123ign does random spark cut to keep to that limit. My tach is very accurate and the function works as advertised. I have a ‘hotter cam grind’ and don’t want to bend valves or blow a head gasket.

2. Problems I have had are mostly with the app:

i) Sometimes it doesn’t load any curve, and seems to run whatever you save as Default.123 - so make that a gentle map with good idle but one where you will notice a big difference under acceleration (and can’t trash your engine). Butt dyno to the rescue.

ii) The ‘map curve’ which does ignition adv/retard from vacuum is difficult to understand at first, I wish it had an option to change it to Hg (mercury), rather than Abs pressure (kP) which the dizzy uses. Yes, you can look up conversion. My default is very gentle, but I have more aggressive maps to run:

Default MAP

No. Abs Pressure (kP). Degrees Crank

1 0 0

2 29 0

3 30 5

4 45 7

5 85 0

6 100 0

7 200 0

Note: If the Map you’re reading is shown in Degrees camshaft, you need to convert to crank by using a x2 factor. That’s buried in the crap instructions. Crank rotates twice for every single cam rotation. Look at the gear sizes on the timing chain! So you multiply cam x2 to get crank degrees.

ii) You can ‘immobilize’ your car in the app, which is a feature I like (I used to run a manual kill switch). It used to work correctly, but now when I go back to settings after disconnecting, the app looks like it’s ready to go. But it isn’t, the engine will die right away. You have to enable, then disable the function. On my New iphone anyway. Not ideal.

Iii) The GPS speedo is rubbish compared to other iPhone GPS apps and Speedos on the market. Sometimes it says I’m doing 153 mph (yeah, right) sometimes 25mph and I’m doing a steady 65mph on the freeway. Mostly. But it’s okay as a check, my analog speedo isn’t accurate at some speeds (very low and above 60mph). So it can help ‘fill in the gaps’.

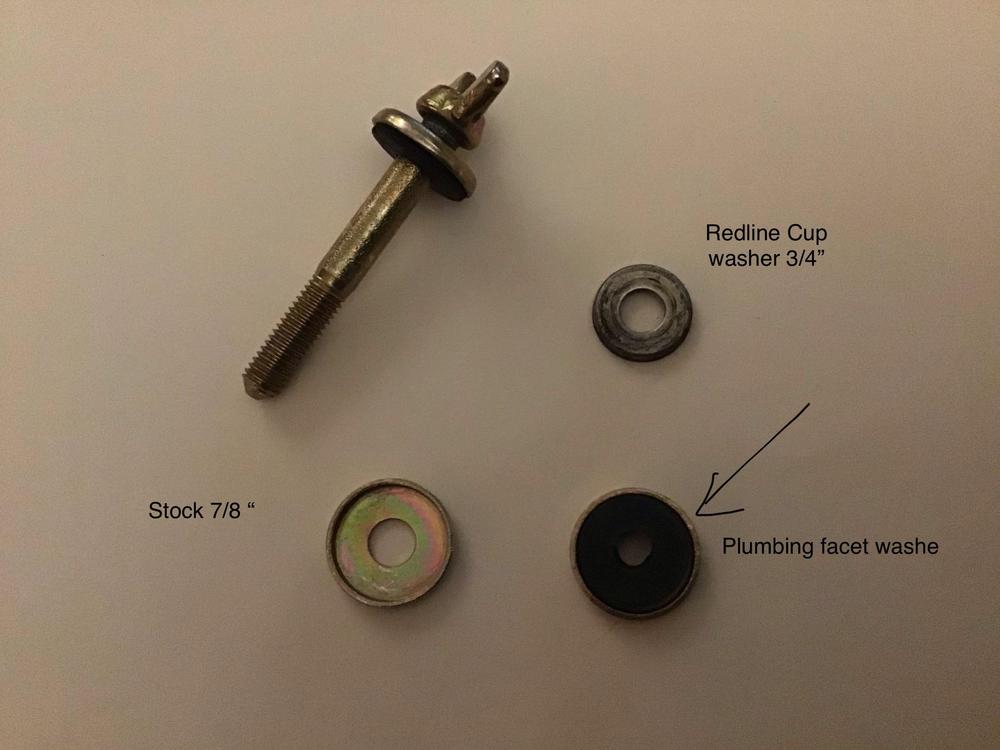

iv) As discussed, the cap and rotor aren’t great, and way too expensive. Replace the cap and rotor with a Bosch one. The ‘71 280SL Mercedes and the ‘65 Porsche 911 2.0L base used the same cap, but that’s from memory. Buy products made in Europe, so Germany or Italy. Go to a Porsche site or Imports parts supply. Dizzy cap for 123ignition 123 Tune+

Bosch 1 235 522 060 or Beru VK102

Part Number for the rotor is:

Bosch 1 234 332 024 or 1234 332 088 which supersedes the 024

WVE 4R1209

For example, a good quality rotor (Italian made) is also available here for $25 shipped: https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.com%2Fulk%2Fitm%2F333529359496

I bought a Bosch cap NOS (in original box) on eBay for around $16, in fact I got two- and was happy. If I wasn’t (cracked or used) I would have sent it back for a refund under eBay/PayPal policy.

Finally, the rotor should not come with a resistor, I’ve modified mine by soldering in a piece of ‘house wiring’ gauge copper wire No problems at all, but you may need to file the top of the wire flatter to have good clearance. Good practice would be to encase the copper wire run in epoxy, so you don’t get unwanted spark jumps. Especially if you run MSD 6AL and a hotter coil.

v) No data logging. A huge disappointment, or has to track the data, why not be able to save a ‘pull’ to look back at what the dizzy (and the car) did. Fix this!

That’s it. My experience has been quite good. These are machines. Cars and engines go wrong. You all know that. There’s probably more I could say, but I hadn’t intended to write a book when I started. If you’re reading this far, you have the benefit of what I’ve discovered. I like the 123i Tune+ dizzy and plan to use another one soon- maybe just the USB one as it could have a single standard tune. This is on a built stroker 3.xL with triple webber DCOEs, hot cam, etc. I’m not scared that if set up correctly, it won’t detonate your engine. It should default to a map that ‘still makes sense’ if it goes out. BTW the holes 4&5 on the L6 are more prone to failure than the others. Don’t ask me how I know...

Subscriber

Subscriber 8Points3,770Posts

8Points3,770Posts