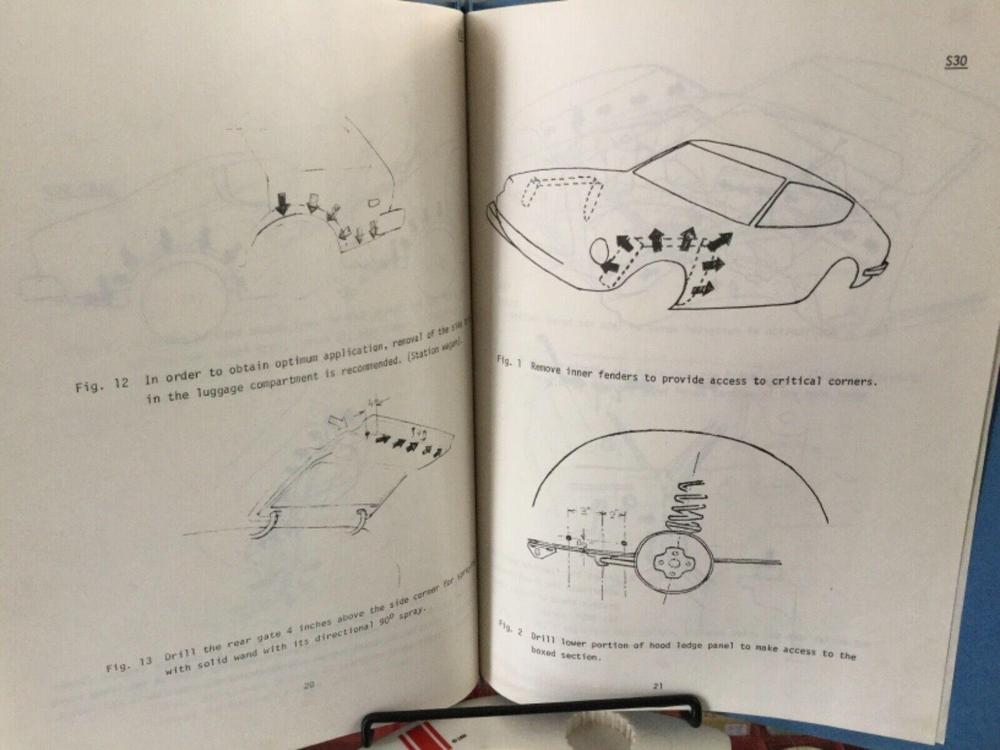

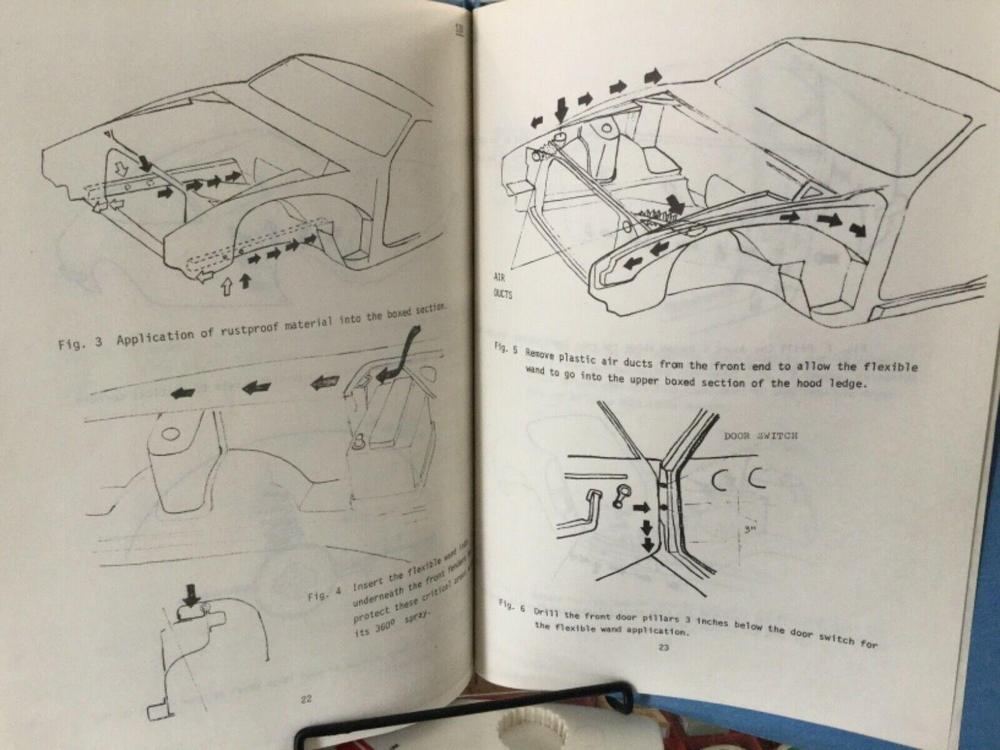

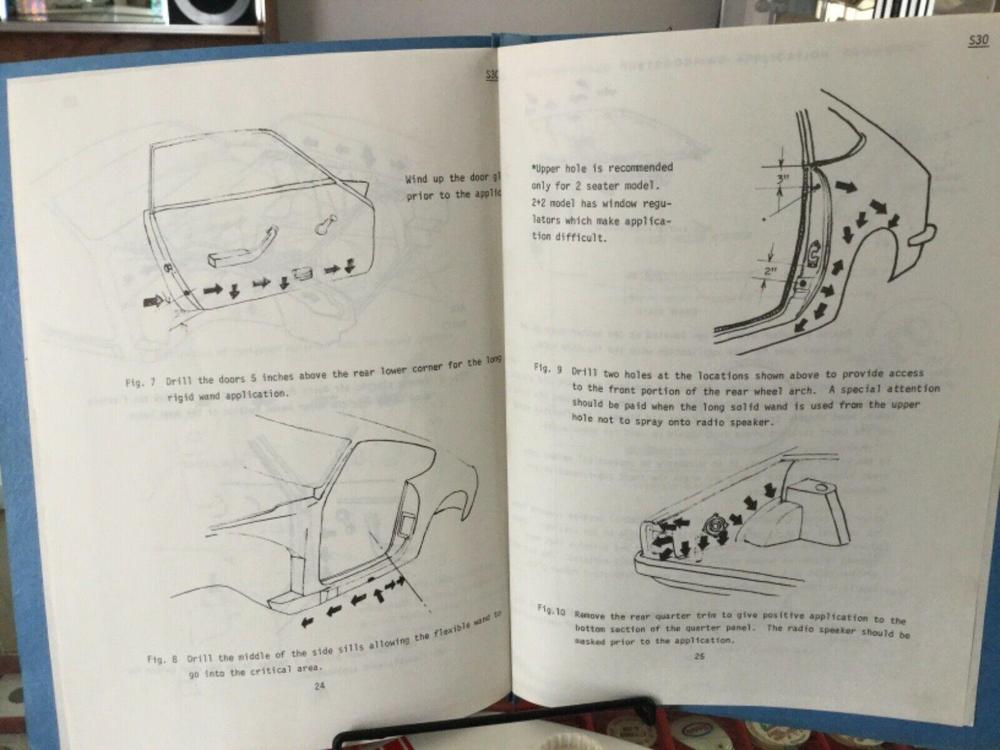

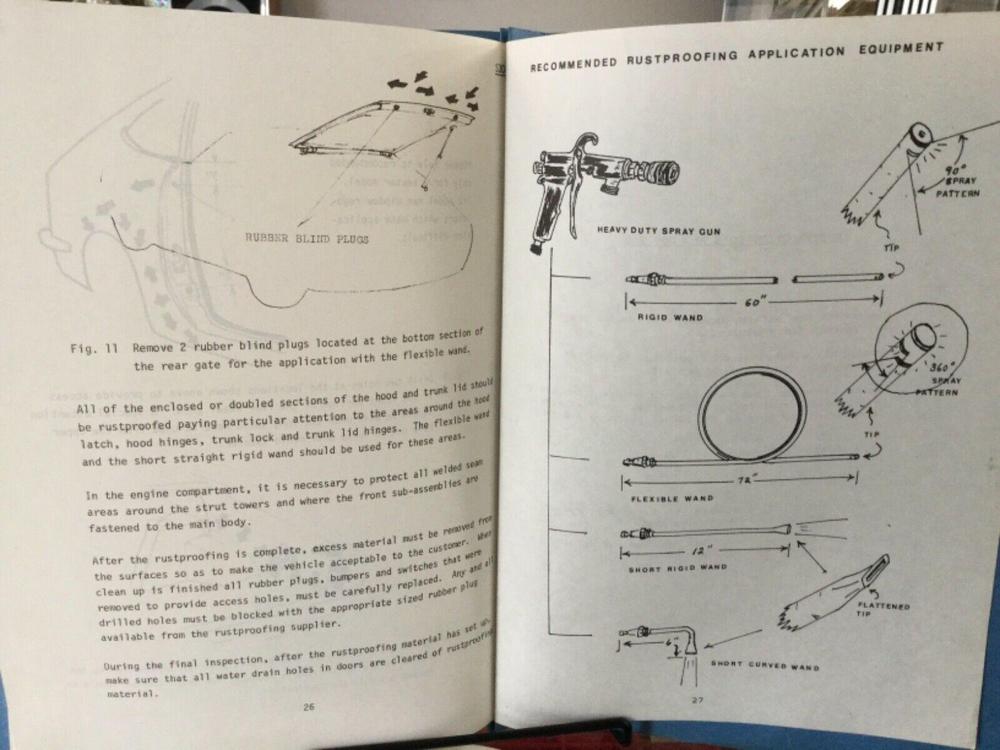

Whoever wrote this manual back in the day had a nice understanding of the Z's prospective corrosion spots. There are some places missed, though:

lower boxed section at the rear of the front frame rails (behind the T/C rod bracket)

underfloor reinforcement rails

underside of hatch floor, where the floor meets the rear valence panel

inner cavity beneath the rear hatch sill plate

full perimeter of the hatch cavity (not just the trailing edge)

windshield posts

front cowl (esp. along all the seams)

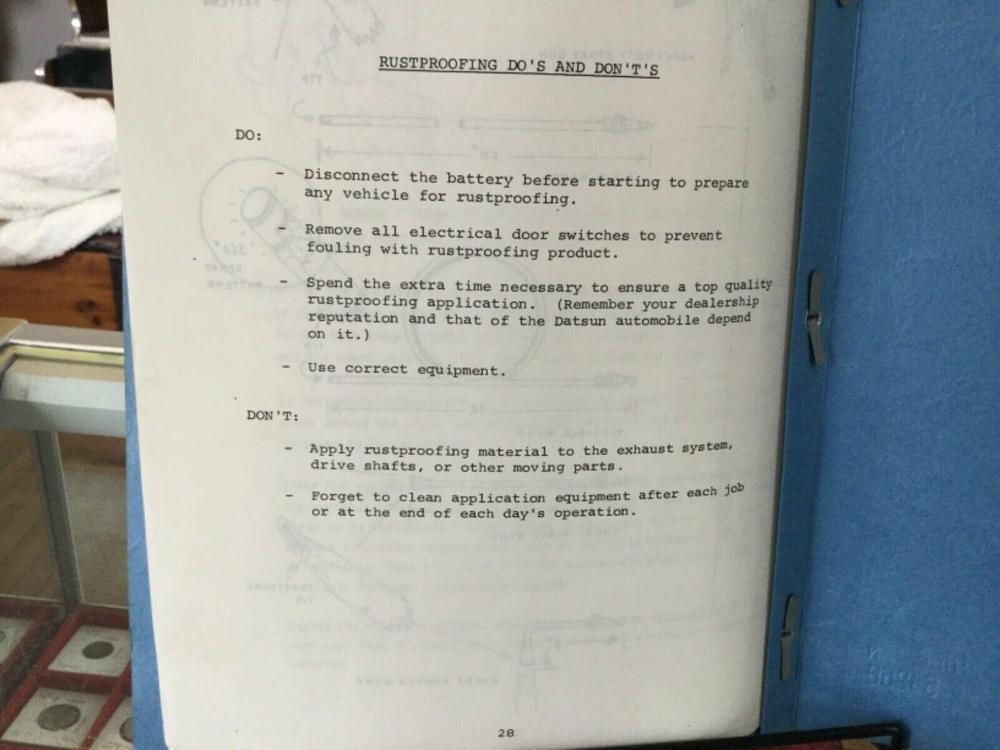

In the 1970's, it seems, many of the popular aftermarket rustproofing solutions were flawed by design. Ziebart (a wax-type treatment) was considered the gold standard, but the material apparently dried out and cracked after several years, creating thousands of crevasses and concealed ledges for salt water to lodge in. As a result, the 'rust preventative' became a rust accelerator. IIRC, there was a successful class-action suit and the company went out of business. Another name in the day was 'Bondeco'. They seem to have disappeared, too. Maybe for the same reason (modern wax-type treatments (e.g. WaxOyl) use better formulations and don't seem to suffer from the same problem).

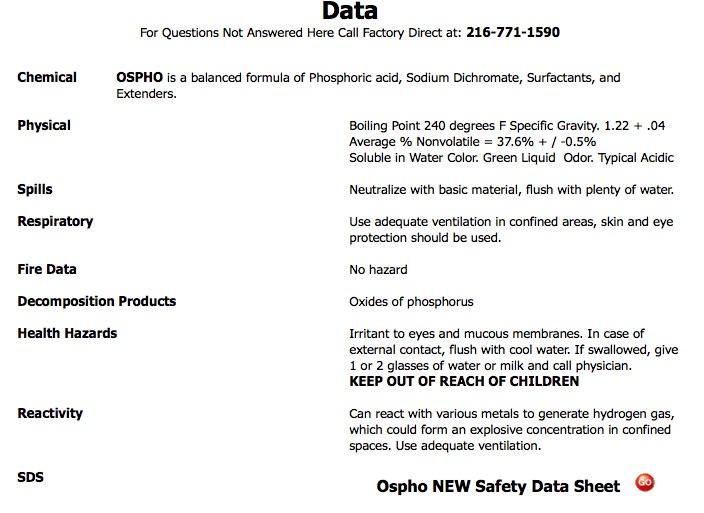

Also in the 1970's, old-timers swore by the effectiveness of oil-spraying. Unfortunately, most of the shops that did this were kind of 'rural' and they used old crankcase oil. Not the sort of thing to be spraying onto your brand-new sportscar! We now have RustChek and the like, which use a clean, thin, perfumed oil that does a nice job of creeping into seams. I have a 2006-vintage car that I bought new and had sprayed once shortly after purchase. It's still solid and rust-free (although at least half of the credit for that probably goes to manufacturers' increased use of galvanized sheet metal).

Subscriber

Subscriber 3Points2,733Posts

3Points2,733Posts