Everything posted by Jeff Berk

-

Steering Wheel Refreshing

I think I paid around $50 or so for my junk-yard wheel and it wasn't even the Faux Wood variety.

-

Steering Wheel Refreshing

I think you're right. I'll need to retrace the Z.

-

Steering Wheel Refreshing

Dutchzcarguy... My intent was to make it narrower, but I liked the feel of it. This wheel is really heavy, I guess because of the epoxy. CO... I've not used the Haas mill yet but its available so its on my bucket list. I was disappointed when I pulled out the original steering hub coin and found it to be chromed plastic. My prototype is attached. If successful, I'll powdercoat it and then buff off the coating on the raised "Datsun Z". I've got Case Western Reserve University within 25 miles that provides community access to all equipment. Cleveland Public Library 30 miles away has limited equipment. Kent State University within 15 miles that plans on giving community access in the next few months. There is a third makerspace around 40 miles away but its too far away. These are all free except for materials and there are at least one more that requires a subscription to use. What I'm getting at, if you check around, your likely to find a community-access makerspace in your area.

-

Steering Wheel Refreshing

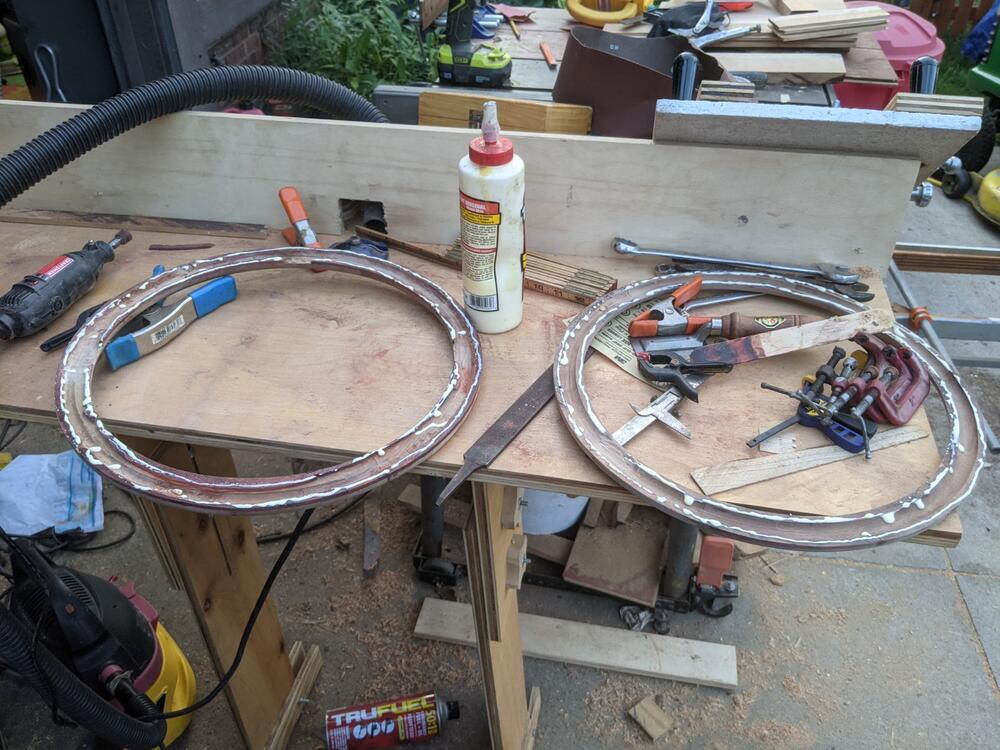

I've been working off and on to make a wood steering wheel from a donner. 1) I stripped the old foam, sanded and powder coated the steel hub and spokes. 2) Cut up some walnut that sat around for 25+ years, soaked it in Cactus Juice wood stabilizer under vacuum, then let it soak up the juice for a week before baking it. 3) Resawed the wood and created two hexagons from the pieces, glued them together. 4) Made a router jig to cut circles, then cut a grove in the wood for the steel rim to fit in, then used the jig to cut the outside and inside diameters. 5) Glued up the two circles, sandwiching the steel rim and a 1/8-inch sheet of blood wood (also treated with Cactus Juice. 6) Routered a round over on the inside and outside of the steering wheel. Screwed up once breaking a 1/4-inch router bit and ripping out a bit of wood. 7) Sanded, sanded, and sanded. 😎 Finished with wipe on varnish. Now I'm waiting on someone to train me in using a Haas Mini Mill to make a new center coin for the padded horn button.

-

Spindle puller tool needed

When I made mine (no longer own), I had machined a pair of flats and they came in handy. Taking bits of various designs, I had used acme all thread and thrust bearings instead of NC thread and a used throw-out bearing. One last thing, I drilled and tapped both ends of the all thread so if one end became damaged, I could use the other end. This is one of those tools that hopefully you only need once. It would be great if one could just borrow the tool from a tool library.

-

Anyone got a clearer photo of the retrobelt install guide?

I'm going to make one. Can't help myself.

-

Anyone got a clearer photo of the retrobelt install guide?

zKars... What is the length of the loop on either side? About 8" (20 cm for everyone outside of the US)? I need to make one of those. Jeff

-

Anyone got a clearer photo of the retrobelt install guide?

SteveJ: I like that belt wrapped around the seatbelt from the transmission hump. My car does not have this (yet).

-

What is your (most) valuable "made it myself" PART! and most valuable lesson learned about Z-cars!

-

What is your (most) valuable "made it myself" PART! and most valuable lesson learned about Z-cars!

I'm looking into stabilized wood (see https://blog.woodturnerscatalog.com/2014/02/wood-stabilizing-v-2/ ) I found a piece of 20 year or so old black walnut that I might cut up and stabilize with clear epoxy. I'm taking photographs and will post the procedures in the future unless it is a complete fail. I plan on generally following the instructions posted on an MG forum. https://www.mgexp.com/article/diy-wood-steering-wheel-part-1.329

- Zx 5 speed rebuild

-

Fenders welded on!?!?!? 280Z (OK no, just... bondo...)

Your pictures I'm sure has made many of us very happy about the condition of our cars. You might need to visit this site in the future: https://www.millsupply.com/auto-body-rust-repair-panels/datsun/

-

HELP Wanted! How do I remove this shift shaft/striking rod in 280Z 5 speed?

-

HELP Wanted! How do I remove this shift shaft/striking rod in 280Z 5 speed?

FYI... After practicing once on a junk transmission, I drilled an access hole so I could get a drift pin in there to drive out the wedge pin like ZKars said. I then tapped the hole I had made and threaded a bolt into it to seal it up. You just have to be very careful in locating where to drill on the outside. I'll add a photograph tomorrow. BTW I also tried to fabricate a small c-clamp to no avail.

-

What is your (most) valuable "made it myself" PART! and most valuable lesson learned about Z-cars!

Thanks for the pointers. I found several sets of instructions on the internet, each with their own variation on the techniques. I ordered a donner steering wheel off of e-bay and will try and source some wood for it from Woodcraft, a chain on this side of the Atlantic that specializes in wood crafting tools and has a great selection of interesting hardwoods. I'll likely create a steering wheel out of some scrap wood first so I don't make as many errors on the expensive wood.

-

What is your (most) valuable "made it myself" PART! and most valuable lesson learned about Z-cars!

I'd (and others I would think) love to see a writeup on how you made it. I can access a fairly complete woodshop with a CNC. A fairly detailed step by step done a few installments at a time would be great. I'd have to find a donner wheel first since I don't want to sacrifice my current wheel in case something goes wrong.

-

What is your (most) valuable "made it myself" PART! and most valuable lesson learned about Z-cars!

Amazing craftmanship! Any chance that you have pictures of the work in progress?

-

What is your most valuable 'made-it-myself' tool?

I also mounted a winch. In my case, I sometimes need to pull my car in and onto my 4-post lift. Pushing it up the lift ramps was too difficult so I attached a box hitch receiver at the other end of the lift. I have a small 12v winch that is welded to a hitch adapter. The winch can then be attached to the lift to pull my Z onto the lift. The winch can also attach to my Chevy Volt or my garden tractor with their box hitch receiver and run off their battery. I thought I was so original with my idea. I guess not.

-

Gauge lights not working, only some.. not all...

Add to that "Spray each contact you check with DeoxIT or other contact cleaner". Be careful since the circuit is energized and you might need to have some spare fuses on hand.

-

fuel pressure regulator location

I'm working on modifying my fuel delivery and need a reality check if anyone wants to comment. My current system has fuel going from no return to a return to try and control fuel pressure and prevent the fuel from becoming too hot while waiting in line between autocross runs. electric pump ==> mechanical pump (MP unable to keep up with the demand) ==> fuel pressure regulator (no return port) ==> "T" fitting ==> SU (4-screw) I was planning on switching to: electric pump ==> mechanical pump ==> fuel rail ==> SU carburetors front ==> SU carburetor rear ==> Fuel pressure regulator ==> return line ==> Fuel Tank fuel system.pdf

-

Gauge lights not working, only some.. not all...

Siteunseen: I had to do likewise, then installed the relays to prevent further damage to the switch since the flip method only works one time. I'm assuming Shawn's switch is providing power since he didn't mention anything about headlights or parking lights.

-

Gauge lights not working, only some.. not all...

Your thoughts are correct; however, your wiring has undergone several iterations of tinkering. There is a potential that someone did a little rewiring. Or, you could be right that all the other bulbs burnt out. I'd like to see how far the power is getting first. How original are you trying to keep this car? I ask because you might consider replacing your bulbs with LEDs (which is not as easy as plug and play).

-

Gauge lights not working, only some.. not all...

Hi again... I don't expect all your dash lights to be dead at the same time. Lets look at your dash lights for now. 1) Turn the lights on and check if there is power to the hot wire going to the variable resistor (a.k.a. dimmer switch) to the bottom left of the dash. The plug should be a three contact with only the top/bottom contacts used (http://www.vintageconnections.com/Content/images/products/66/1.jpg) This will tell you if power is getting this far. 2) If you have power, try jumpering the harness wires at this connection to bypass the resistor. If the lights come on, you likely have a bad dimmer switch. If not, AND there was power to the switch, you'll have to start testing the connections at the bulbs sockets. That will at least give you an opportunity to see if the bulbs are burnt out. BTW: The URL for the connector picture is from Vintage Connections. That is likely the best place to purchase replacement connectors for your 260z.

-

What is your most valuable 'made-it-myself' tool?

Part of the reason for owning a Z and subscribing to this site is to learn something now and then. Fel-Pro does a good job of explaining the concept and included an example for a Subaru where the head bolts had to be tightened in two steps, loosened in two steps, and then tightened in two to three steps in order to get to the "yield zone". https://www.felpro.com/technical/tecblogs/proper-installation-use-t-t-y-bolts.html

-

What is your most valuable 'made-it-myself' tool?

OK, I have to ask... What is the purpose of a bolt stretch gauge? Please don't say to measure the stretch of a bolt. A little background please on this cool-looking tool.