Everything posted by Zed Head

-

1972 Float Adjustment ...

4 1/2 year necro post started it all. 4 1/2 months and 26 pages later...it continues. The internet.

-

Stalling issue(under throttle)

Here's that other thread. It has a video.

-

Stalling issue(under throttle)

If you're still in gear with the car rolling and the clutch engaged (wheels turning the engine), and the tach doesn't match engine speed that's a sign of no spark. The tach is just a spark counter. I was posting in another thread recently about the Fireball system. If you have the optical trigger under your distributor cap in place of points then some trickery will be necessary if you want to keep avoid getting a new distributor. Or you can just get a 280ZX distributor. Or a 123 ignition system. Many options.

-

Stalling issue(under throttle)

What does your tachometer do when it "stall"s at high RPM? Does it drop like a rock even though you're in gear? Might be an ignition problem. You have one of the early electronic ignition systems.

-

Stalling issue(under throttle)

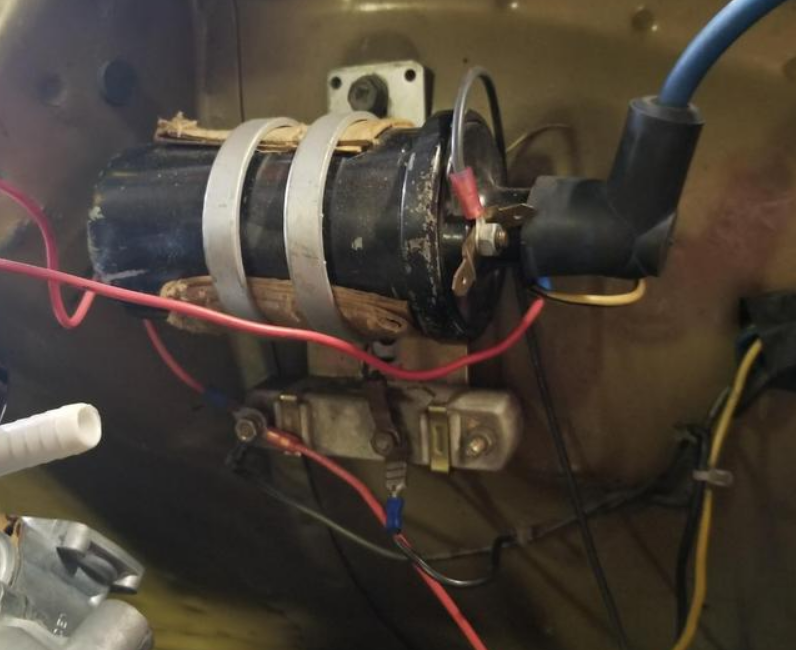

I assumed that these things were in line with the filter in my other post. Maybe not. What the heck are they?

- remove tranny requires engine removal on 73 240?

-

Just what the Doctor ordered. 1977 280z

You have access to install an in-tank pump, and improve on the stock baffling. The 280Z tanks are known for a poor baffle design that leads to fuel starvation on left hand turns when the tank gets down below 1/3 full. Consider.

-

Stalling issue(under throttle)

Funny, I saw the AC comment and completely missed the first post. Didn't click. To add to and follow SteveJ's comment, replace those filters. With just one. Each filter adds a pressure drop, even when clean. Pretty sure I see three in serial. That's a lot of work for the fuel pump.

- remove tranny requires engine removal on 73 240?

-

remove tranny requires engine removal on 73 240?

I've installed the engine and trans together, it's not difficult, just bulky. A load leveler would help a lot. My biggest problem was lifting the tail of the transmission up to get the crossmember under it. Since then I've learned about pulling it up from inside with a rope. The 2+2 parts should fit fine except that you'll need a 280Z mustache bar and "dog bone" for the diff. The dog bone is what people call the brace between the two suspension mounting points in the back. It's curved to make room for the larger R200. You could do the transmission first and the diff later. There's always more to do...

-

remove tranny requires engine removal on 73 240?

It's easier with a good transmission jack. Removing the engine will add much more difficulty to the whole project. There are some tricks you can use, like cutting the heads off of extra long bolts and running them in to the mounting holes to use as guide pins. Use the cars scissor jack to move the back of the engine up or down, for fine orientation. Make sure the clutch disc is perfectly centered, don't use a loose clutch alignment tool. Stuff like that. Not too hard to get done.

-

Mikunis, but want a daily/recreational driver

Did your mechanic tell you that? Power band is controlled more by cam profile and/or cam timing.

-

78 280Z ignition condenser

Clean the T plug connection first. I've had mine lose contact and look like a dead alternator.

- Field-Find 3 Datsun 240Zs

- Field-Find 3 Datsun 240Zs

-

Field-Find 3 Datsun 240Zs

People want photos. Take a picture of the engine, and make sure you get the serial number stamped in to the flat spot below the #6 spark plug. Get pictures of the bottom of the car. Get pictures of the other sides of the cars that don't show both sides. Get better pictures of the insides. These cars are interesting but full of work. They won't sell themselves.

- Field-Find 3 Datsun 240Zs

-

78 280Z ignition condenser

That was a coincidence. A red herring, as they say. The condenser would have no effect at all if the wire was broken. You might have a short somewhere or a voltage regulator/alternator going bad. Your car has a voltmeter, not an ammeter, so what you saw was voltage dropping to 8, when it should have been 12+ or better. That's a sign that your battery voltage is low and that the alternator was kicking on and off. When it was on the voltage would jump to charging voltage, when it was off it would drop to the level of a dying battery with a load on it. Check your alternator is the short suggestion.

-

Ignition circuit wires all smoking

Some of these wires get hot and smoke? You have a lot going on there. The Start ignition system is different from the On ignition system, at the ballast resistor. I would check those wires closely.

- 11 replies

-

-

- 1

-

-

- 260z

- datsun z

- electrical

- fire!

-

Tagged with:

-

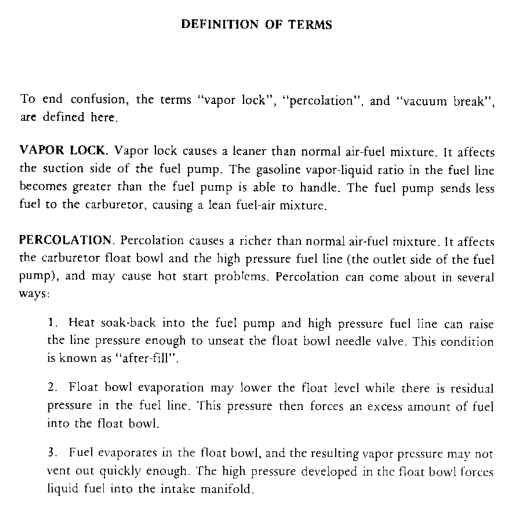

vapor locking on 73 with 71 carbs PERCOLATION!

-

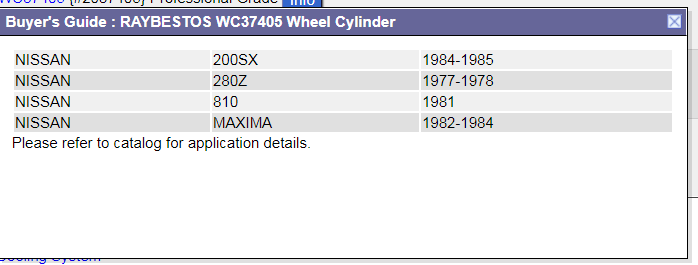

77-78 Rear Wheel Cylinder Brake Rebuilds

-

280 Z Fuel Injected Engine

How much (dollars) and how much (is included)?

-

Crane XR700 & Tachometer

Good luck. Always good to have a spare setup waiting when you're working with old parts. Is the spare distributor from a 280Z? Check under the cap to be sure. I think that a person could make that optical trigger work, with a separate power wire. It's a project for nerdy electronics types though. I'd probably try it if I had it in my garage.

-

Crane XR700 & Tachometer

You have an interesting situation now. You have the XR700 optical disc in the distributor, which uses a different trigger signal for the ignition module. It might work but we'd need to know what the XR700 optical unit puts out or controls. It might take extra wiring, and electronics knowledge. Some study is required. If you can find a 260Z or 280Z stock distributor that would be an easy wiring job. The stock units create their own voltage. If one of the electronics guys wants to take a stab at making an XR700 optical unit trigger a GM HEI module, feel free. The GM HEI module is often used to replace the turbo 280ZX ECCS "ignitor" which uses a 0 and 5 volt square wave.

-

vapor locking on 73 with 71 carbs PERCOLATION!

The vented hood didn't show up until 1977, on the 280Z. One thing that I haven't seen tried is insulating the carburetor itself. There is lots of surface area, especially the domes, and it will absorb both radiant and convective heat. It's aluminum so will conduct that heat rapidly to the surrounding metal, down to the float bowl. If it was mine, because I'm not really concerned with appearance, I'd wrap some sort of insulation around that dome for starters. If it helps, consider insulating the bowl also. I've used that metalized bubble material on my EFI system and it works well. It's plastic (Mylar [PET], I think) but withstands the heat well except for the really hot spots, where it has crinkled up. Some zip ties and scissors and you're set for a quick trial run.