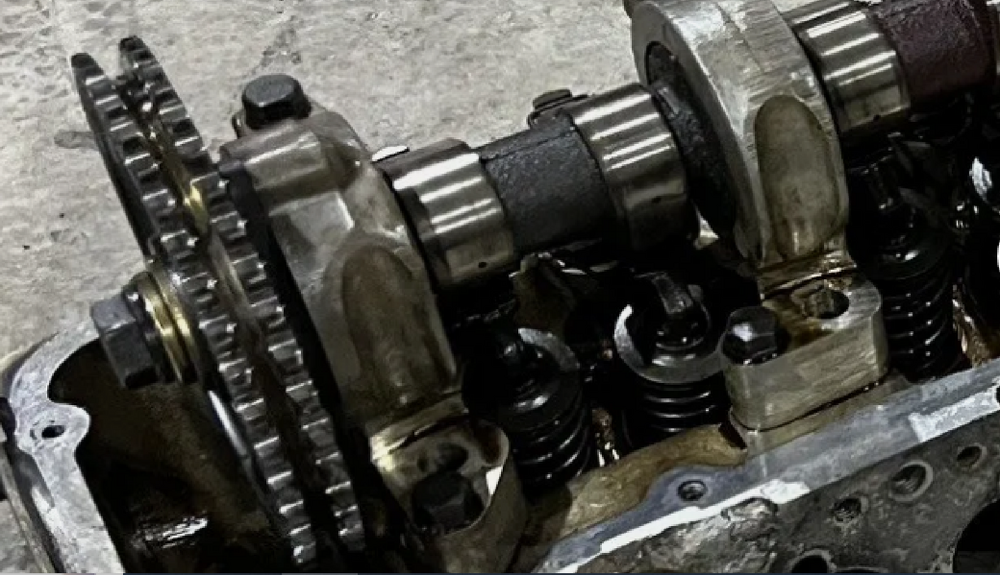

As @Captain Obvious said, the hatch lock is the easiest when compared to the door and ignition locks. To get it apart, you just have to straighten the 3 little tabs on the backside of the stainless trim ring. The trim ring (1) then releases from the lock case, and you can take out the tumbler assembly (2) with the sleeve (3) still on it. To remove the sleeve, you just have to depress one of the "wafers". Then (2) slides out of the sleeve (3). You can then swap out the wafers to match your key.

The ignition key and the door locks are more difficult to take apart and put back together. The keying kits I bought off of eBay had replacement stainless steel covers for the door locks.

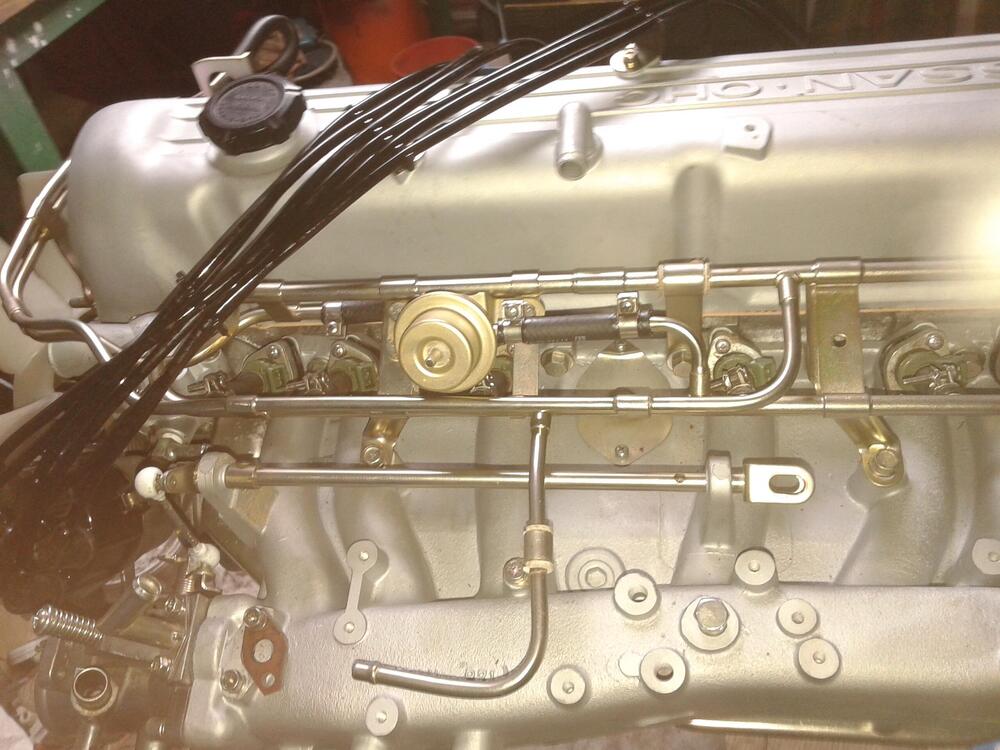

Though this is picture after putting on the replacement cover, you can see here that the cover edge is simply bent around the circumference of the lock case.

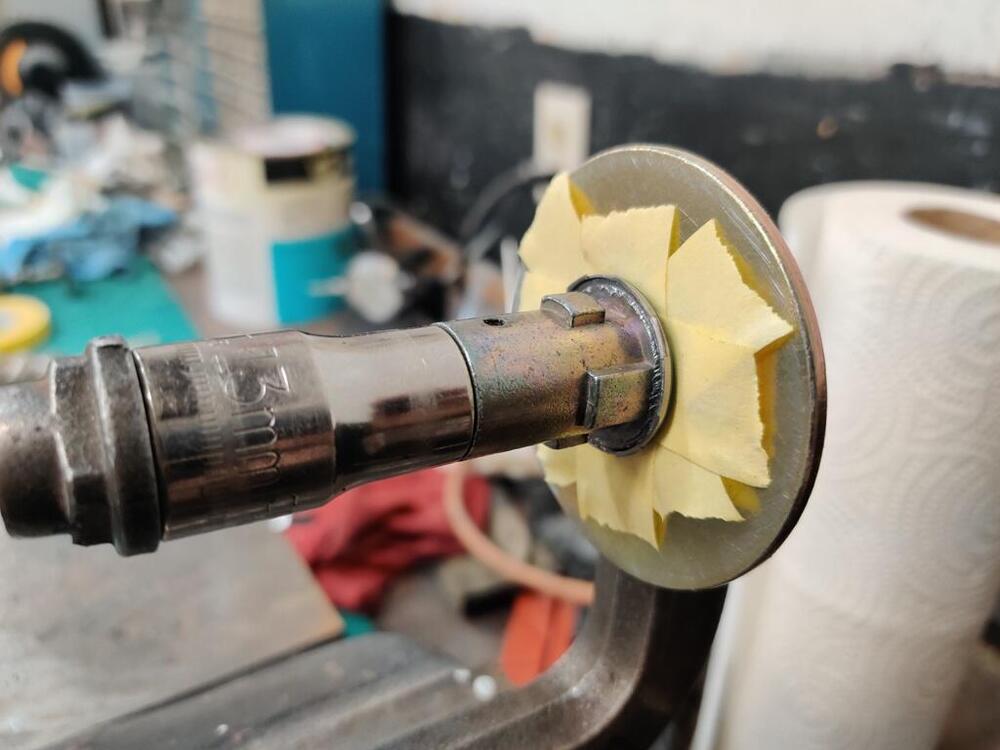

To get the old ones off, I used an air powered cut off tool with cut off wheel attachment, and simply ground the edge of the existing stainless steel cover (for one half or 180 degrees) of the periphery. I use the flat surface of the disc and not the cutting edge. It is easy. When the stainless cover edge gets really thin, it is easy to pick at the backside fold, and break it away from the case. Then the old cover is easily slid away from the case. With the cover off, as with the hatch lock, you can remove the lock apparatus from the case and change out the wafers.

The new covers in my kit.. have these extra tall tab areas (4):

They are not needed and would interfere. So, I ground those down with the cut off wheel (again side of wheel - not cutting edge). Then I put several layers of tape to protect the stainless cover surface:

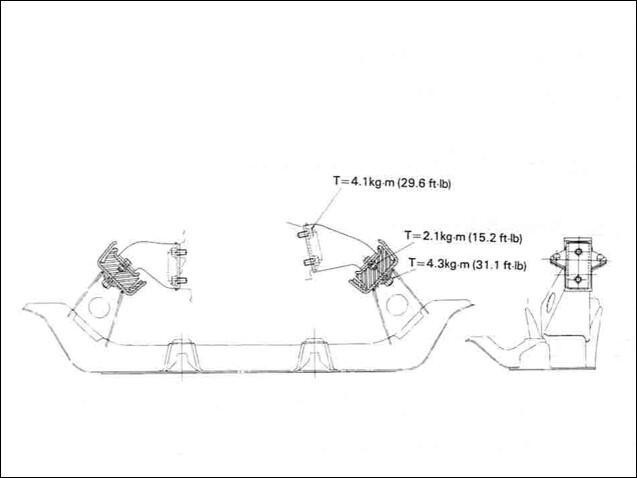

Finally, I used a high quality C clamp - clamped into my bench vise, along with a large, thick washer (for backing against the new stainless cover, and a 1/2" drive socket to press the lock tightly against the washer... and used a hammer and flat punch to work the edge of the new stainless cover down around the case flange.

I am in the middle of this part of the work to finish up the door locks, and will put finished pics up soon. Maybe with this info, you can convince your locksmith to give it a go?

Subscriber

Subscriber 4Points11,142Posts

4Points11,142Posts Subscriber

Subscriber 3Points1,282Posts

3Points1,282Posts