Well, a huge positive update for anyone thats bothered to keep up with this thread for the past sixteen pages.

I ordered a secondhand distributor from a known good running car (claimed by seller.) I can't say for sure if the reluctor wheel on my distributor that I pulled off was chipped before I took the wire wheel to the tips to clean it off a bit, but part of me thinks the reluctor wheel wouldn't be that weak to chip off like that with a wire wheel brush and minimal force, but again, I haven't worked on a distributor powered car in awhile, and I've never cleaned a reluctor wheel until now.

So I installed the "new" distributor after cleaning it up a bit, installed the cap and rotor, reconnected plug wires, etc.

I started the car and it fired up and the RPM's immediately shot to 1,500 and held there, which I assume would be characteristic of a cold engine, as thats typically where I've seen them hover. I gave it some gas, and the stumbling was gone, the car revved happily, with the tach reflecting that.

At this point it was burning some oil though, blue smoke was filling the garage, so I shut it down. I'm not sure if that's just from how long it sat, or if theres an issue with valve seals or piston rings, but it's my goal to get the car out of the garage and into the driveway in the next week, change the plugs out, and just let it run and get up to temp and see how it works. I need to bleed the brakes and install new pads/rotors on the front (and a caliper, the right front was sticking I believe, but I bought two new ones, so that's going to happen as well.)

At any rate, The main problem *Appears* to have been solved with the replacement of the distributor. Whether more issues will show their face now that the car is actually firing correctly remains to be seen, and I wouldn't be surprised if that were the case. I'll have a more full report to make once I can let it idle for a few minutes and get up to temp, but as of now, it starts and runs much more clean, I can give it throttle and let it rev as high as it wants, where before it would hit a wall at 700~ rpm and just refuse to rev no matter how much more throttle was applied, and adding throttle could even cause it to die.

A minor victory, but a satisfying one! I still need to figure out the issue with the blower motor not working on any setting, and the turn signal only working on the right (slowly), not working on the left whatsoever, and the back lights not working all the time when the headlights are on, most likely the switches if I had to guess.

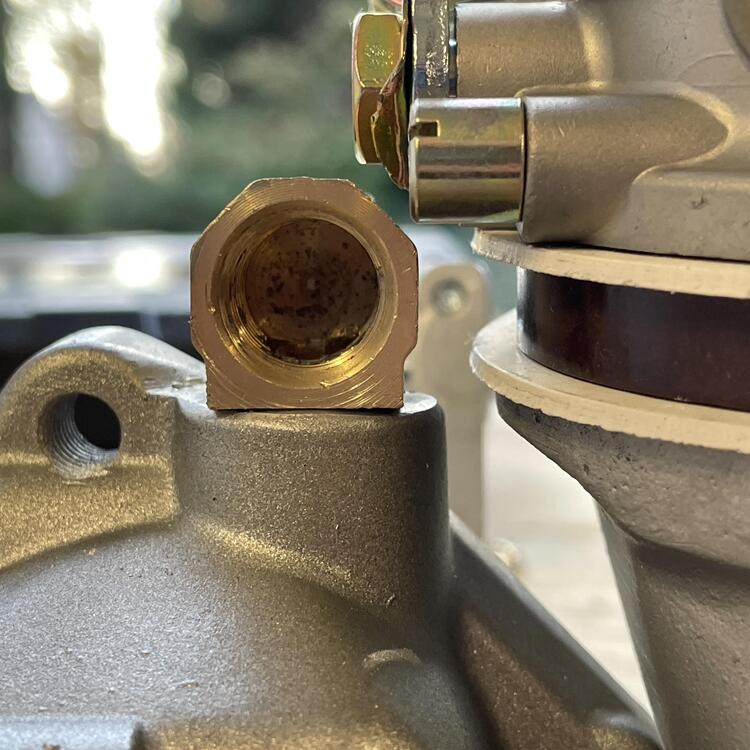

.thumb.jpg.6520c60373fa3e79005e531752cb35fe.jpg)