1. EFI Conversion

I am not going to tell you every detail about how to do this, just to make the point that while it can be daunting, it is SO WORTH IT.

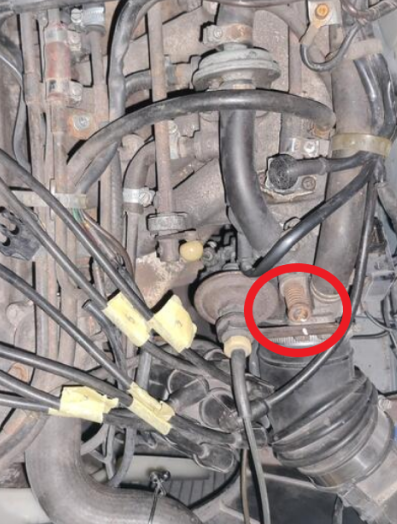

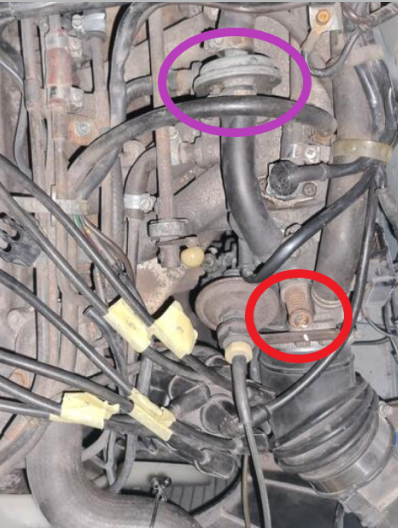

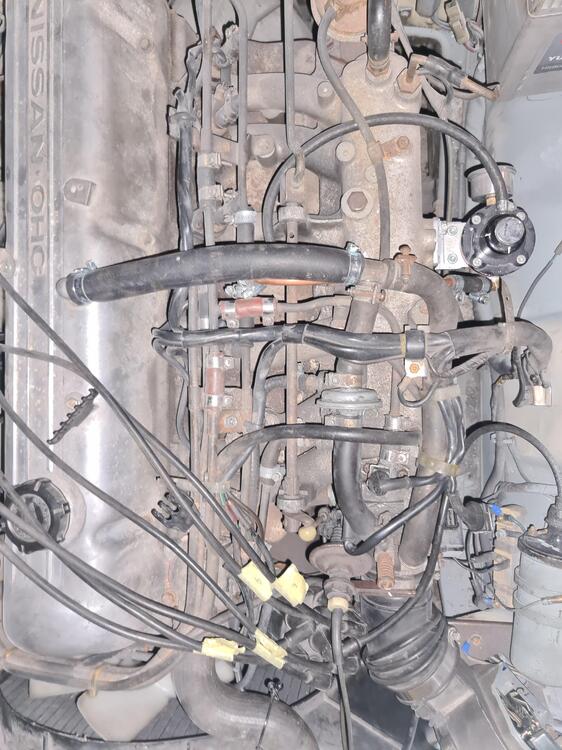

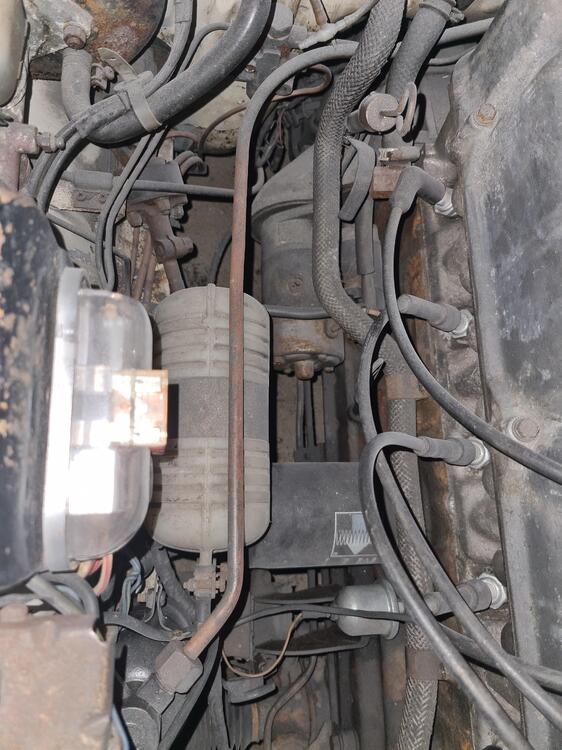

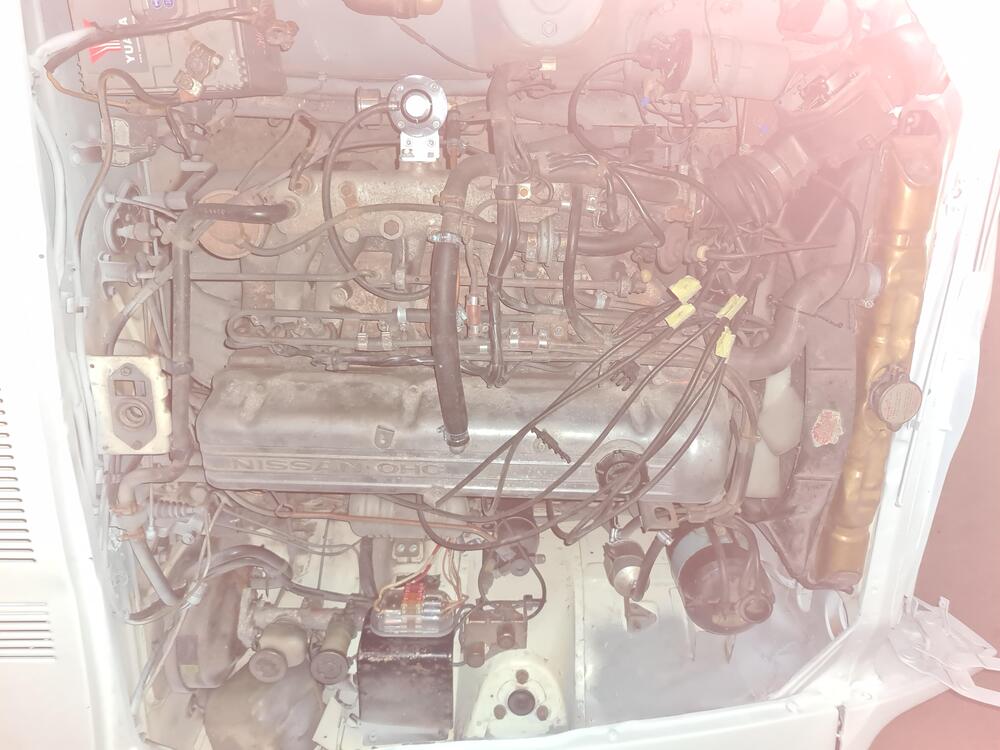

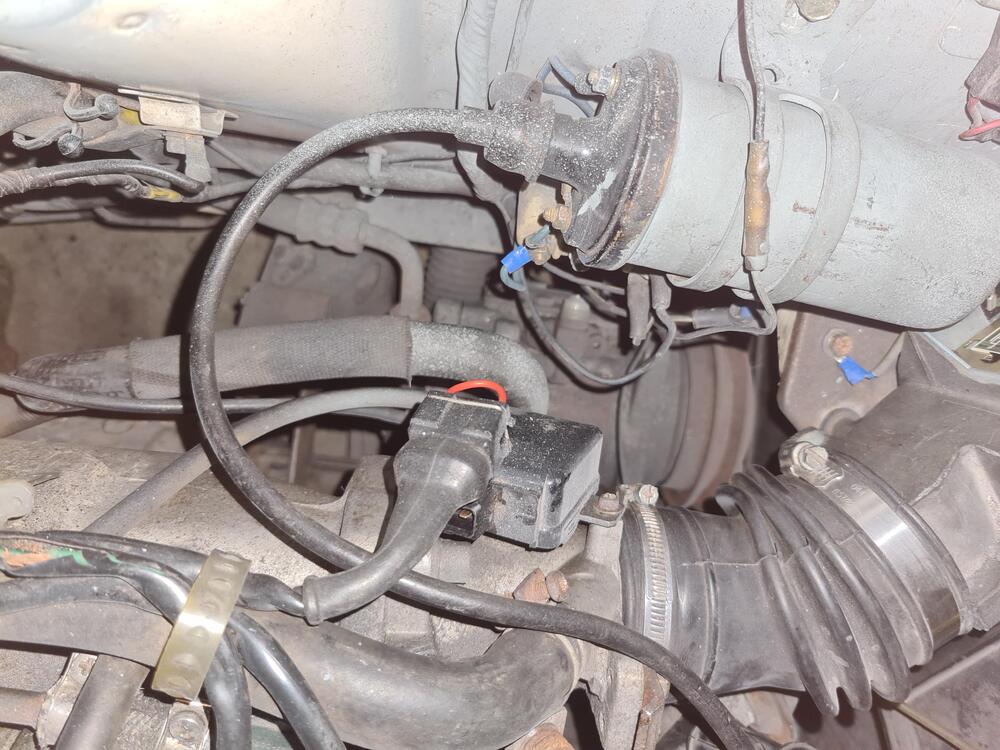

I did an EFI conversion on my “other” 69 510 back in 2018 and have never looked back. The increase in reliability, drivability, and maybe mostly the ability to be informed about the state of the engine, and the ease of monitoring any input or output has made it a pleasure to drive. I have done literally NOTHING other than routine maintenance in 5 years…. Hop in, drive it. Park it for the winter. Hop in April drive it till it snows. Repeat. It’s cool vintage looking. I used the Jenvey Heritage Throttle bodies that look like dual webber carbs. I get the classic look and appeal but it runs like a modern car. On this one I’m doing more or less what Datsun did with the 280z EFI, just the 4 cylinder version of that. Bit of rare kit, but that makes it fun. “L18E” is the thing to look up if you want to find out more. I’m only using the intake manifold.

The high tech part of this that I will identify and name is summed up in one acronym, CANBUS.

If you do an EFI conversion, get a system that has CANBUS at it’s heart. It will be give you control and monitoring in a hundred ways.

I used HALTECH on the first 510, I’m using MegaSquirt 3 Pro/Evo on this one.

There are “easier” options, like using a 4 barrel manifold and bolting on Holley’s EFI system with a 4 barrel EFI carb looking thing. But make no mistake, this is not for the faint of heart no matter what you do. Perhaps the hardest part is the need for an “outside”, ie a tuner to make it all run right after you build the hardware.