My first Z has a story, less about the car, and more about the guy I bought it from.

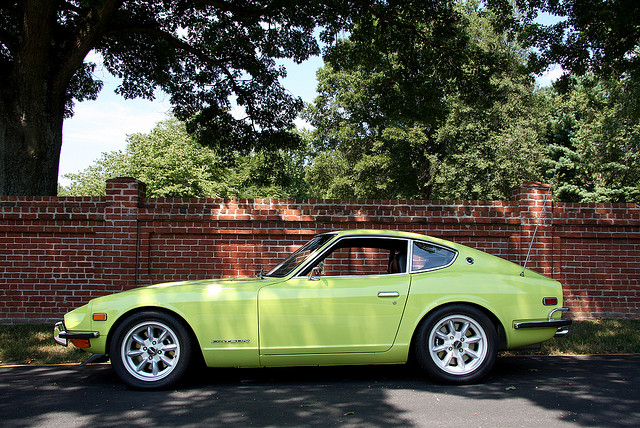

First, the car.

HLS3041924, build date 8/1/1971, originally red with black interior. In 1979 it began a life as a road race car, running ICSCC and SCCA events in the Pacific Northwest, with a Conference log book. It was in pretty sad shape when I got it, having 8 or 10 layers of paint, and 10 years of thrashing around road race courses in Oregon, Washington and British Columbia. It was lime green on the right side, bright blue on the left, and had an orange stripe down the middle.

The guy I bought it from is the story.

He had a reputation as a rolling chicane, never doing well with the car.

Some time before he decided to sell the car he had gotten divorced. It was a pretty messy affair. His ex wife had been messing around with his best friend, who was also the mechanic for the race car. She got the house, and the kids, and was shacking up with the now ex best friend.

Oh, and the house was next door to his parents house.

Oh, and she had a restraining order against him, and wouldn't let his see his kids.

So he couldn't see his kids, and couldn't visit his parents because they were too close to her.

The day I looked at the car to see if a deal could be made, he was edgy. Wearing a windbreaker, I noticed one pocket hanging very low, as if it had something very heavy in it. Indeed, at some point during our conversation, he mentioned the ex wife, ex friend, parents, restraining order, and mumbled something about having a solution, and patting the extra heavy pocket on his jacket.

We made a deal, I returned the next day, paid him, did paperwork, loaded the car up and went home.

A day or two later I saw a news story about some guy in Puyallup that had gone to his ex wife's home, shot her, their kids, her boyfriend, and then himself. I was about to dismiss it as more of the crazy stuff that is always in the news in Pierce County when they mentioned his name.

It was the guy I bought the race car from.

Subscriber

Subscriber 4Points11,142Posts

4Points11,142Posts