Realizing that a key next step in the body work for this car was to determine the final fitment of the top, inside edges of the fenders, I proceeded with mounting the hood over the weekend. In order to do that, I had to first modify the angle brackets connecting the car at the bumper bolt locations to the rotisserie. I had to cut a small section from them to get freedom of movement for the mounted hood hinges. With that out of the way, I proceeded to struggle mightily with aligning the hinges and getting the hood to "sit down" all the way. I didn't take pictures of them, but it is important to note that the "hood - bumpers" (reference A in the drawing), don't just align the hood laterally in the engine bay opening. They are POSITIVE stops for the hood depth - caps added for emphasis! I put them on before final adjustment of the height of the fender inner edges, and they were keeping the hood from shutting enough! Suffice to say... you must leave those off when aligning the hood and fenders, and add them later (as Nissan did after the car was painted at the factory).

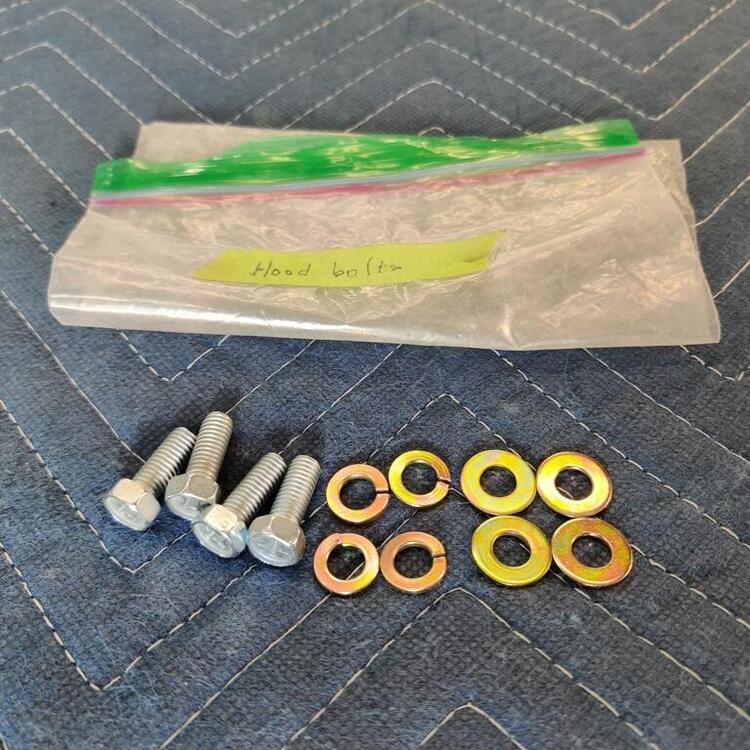

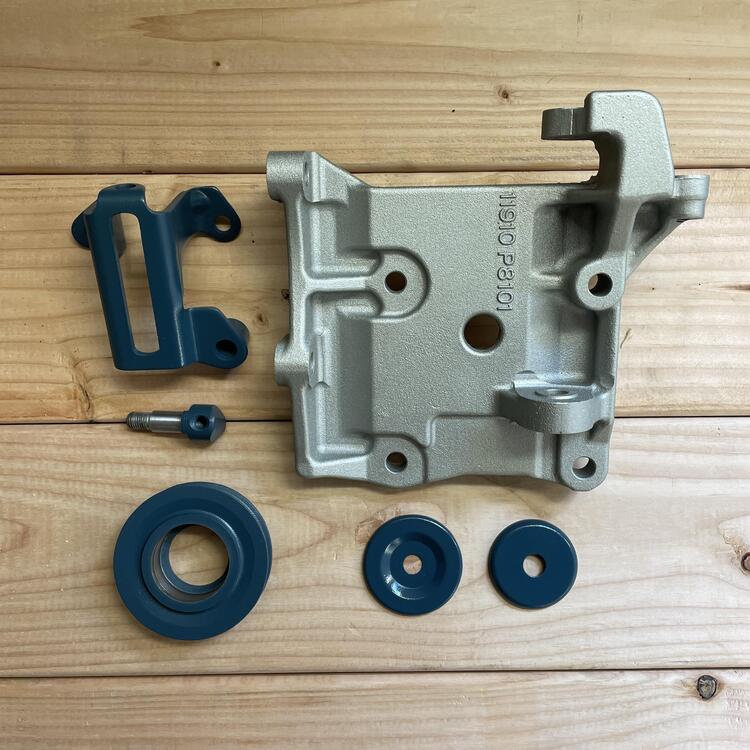

Hood hinge and hood bolt for documentation purposes:

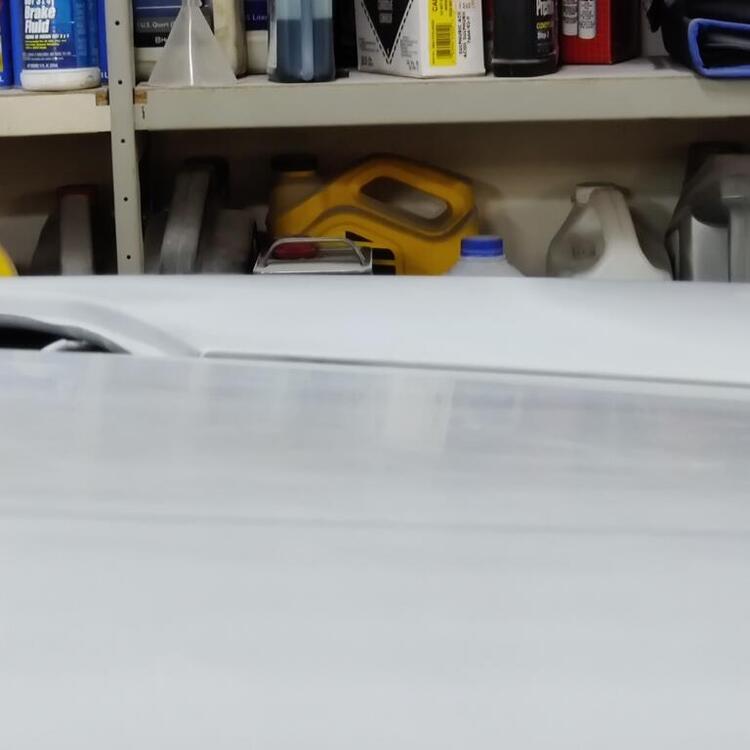

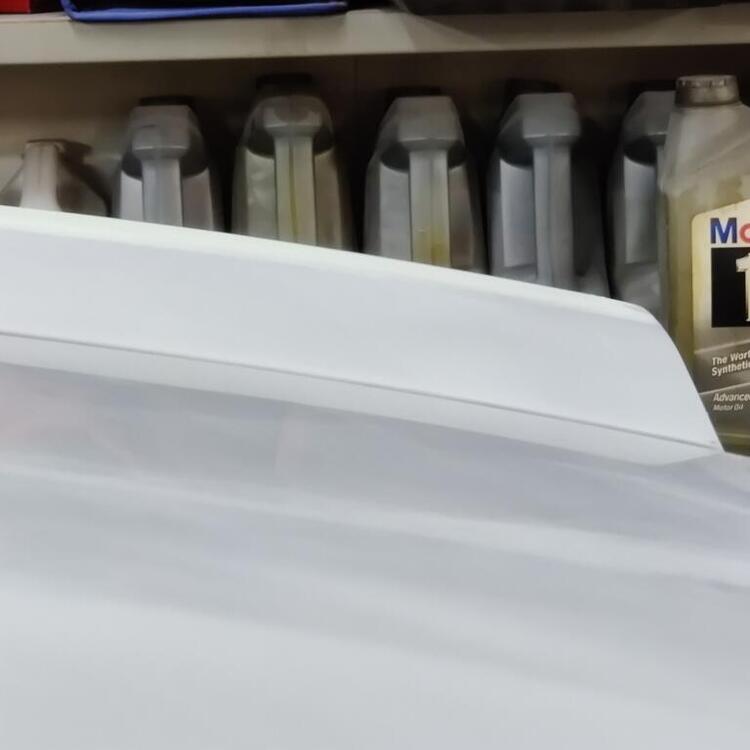

On to details about the chore of aligning the fenders with the hood. After adjusting the hood and fenders as well as possible within their "ranges", the left fender was sitting up higher than the right, a little more in the back (note the inside surface of the fender inner flange can be seen from this angle in the first pic, and less so toward the front of the car in the second pic.

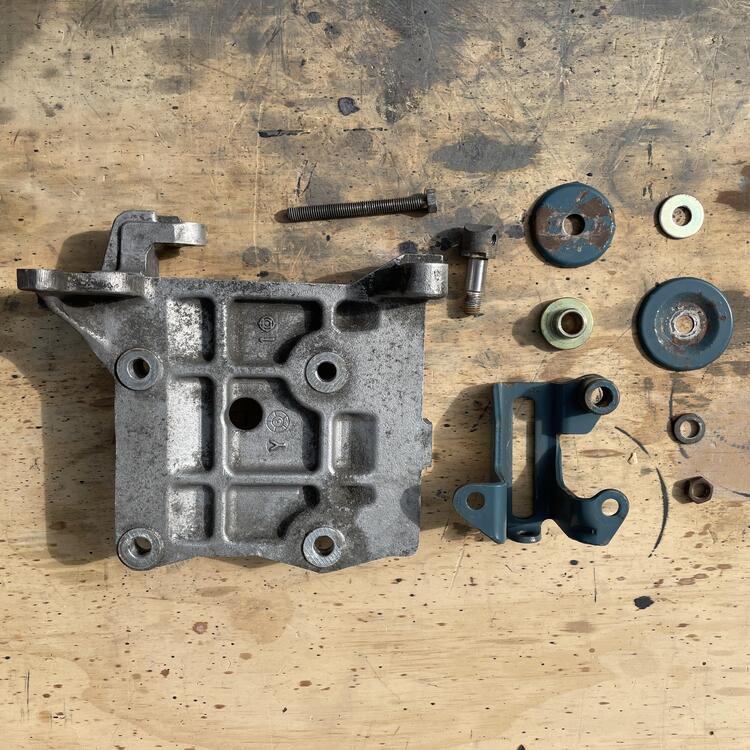

Well, I couldn't push the inner edge of the left side fender down any further, as it was at the full range of adjustment using the bolt hole openings on the fender inner edge. That was odd, because I wasn't having the issue with the right side fender. So, I began to compare the two:

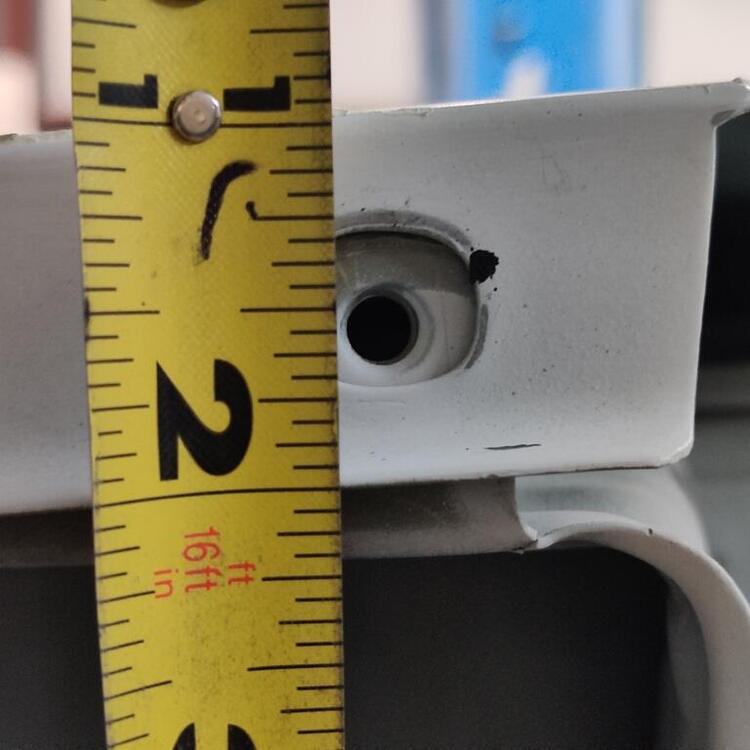

Left side vs. right side - in that order:

It is a little hard to see, but perhaps you can make out that the left side fender has about 1 and an 1/8" from the 2 on the tape to the top surface, while the right side fender has about 1 and a 1/32" from the same 2 on the tape. To get the driver side fender inner edge to align with the hood surface properly, I had to open up the slots in the fender. I did this by using a die grinder and protecting the opening with a flat steel plate:

After a few rounds of this on the fender bolt holes, I was able to push the fender down enough to align with the hood properly. I then tightened those inner fender edge bolts for the last time and locked in the fender top surface position. Of course, I then had to "touch up the body work on the fender top surfaces on both sides. I keep learning my own lessons over and over again: 'don't do body filler work on these panels until they are in final position'.

Tonight I scuff sanded the inner surface of the hood to ready it for primer filler. The tops of the fenders, and inspection flaps are also ready for primer filler. With any luck, those will be final coats of primer on those areas - more panels are reaching the point where I can switch to wet sanding with 240 grit. After that, I should be able to progress to 400 and then 600 to finish out the sanding process.