Yes! On monday the shell is going back to the bodyshop. I chose a new panelbeater with a bit more professional background. The other one was OK, but this time it goes to a specialist which is usually handling cars in a more exclusive price-range. Also he's not alone but has a hand full of people on hand and compared to my previous guy - has all the tools required in-house. Also he just seems a bit more of a "do-er" and less of a "talker" - my kind of guy. And he promised me to complete the body until the end of the year for a fair price. So let's have the fingers corssed that the project is back to 100 again now...

This means i had to prepare a few things for the bodyshop. Aside from a few drawings with measures and dimensions and other details, he asked me to prepare the passenger side. the first thing he's going to attack is fix and finalize the work of the previous guy. on the first look he told me the work was pretty good, but there are a few small details to rectify especially the rocker panel that doesn't align with the door. something the previous guy wanted to fix himself before i took the car back...

So first: there is still a lot of media from the sand blasting falling whenever you move the car...

So i took out the vacuum cleaner and tried to suck out all remaining sand wherever possible (2nd attemt, and for sure not the last one...)

The previous owner t hought it was coo to have the car "clean" and closed all the holes for the fender and hood emblems. Luckily i have a good fender with the original holes in stock. so i took measures there

...and transferred them to the other fender, to drill the holes. I'm quite satisfied with the result (only temporary mockup, emblem is not fully pushed in)

Ignore the black marks. they were wrong, but after drilling, i decided to give the holes a bit of rust protection by spraing it with some primer. i probably went a bit over board with the sprayed area 🙂

Time to put it on the car:

The panelbeater also asked me to install the doors and locks so he can align everything neatly and make sure the panel gaps are nice everywhere.

And the doors side. Feels good to "assemble" something, even though it is only a temporary mockup with some "scrap" parts. Will be nice to install the other set which is freshly zinc plated or rechromed...

While working on the doors i also realized there is some rust on the welds inside the door skin. The welds came from the previous panel-beater, who made sure the bodylines are there again. it seems the previous owner also "cleaned" those.

i cleaned the welding spots with a brush and added some rust conversion primer there (no photo of that):

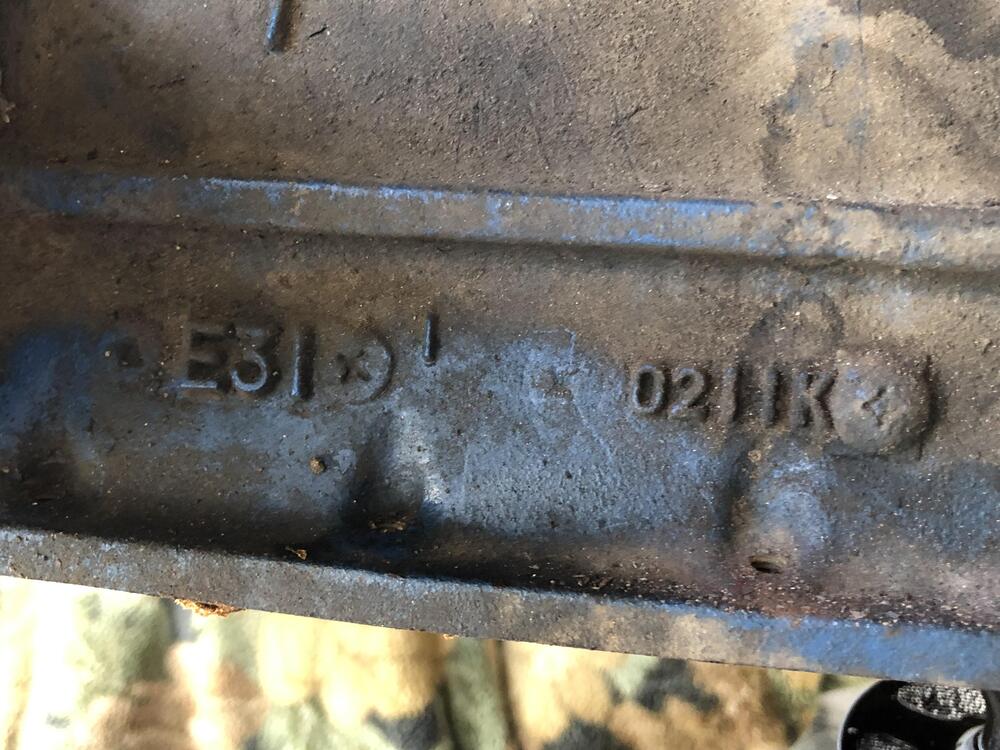

While sorting through the doors parts i thought it was about time to give my "new" sandblaster a try:

Worked pretty well, except i realized my compressor is too small. Luckily i already have a deal with my father-in-law to exchange ours (he needs a smaller one, i can have his more powerful one):

If everything goes well you'll see some picturs of this car being loaded onto a trailer on monday, along with a load of parts. So happy to see the project taking up speed again...