Sorry you’ve had trouble. One manufacturer’s Strut Cartridges should not be used with another manufacturer’s Gland Nuts, so let’s see what we can figure out.

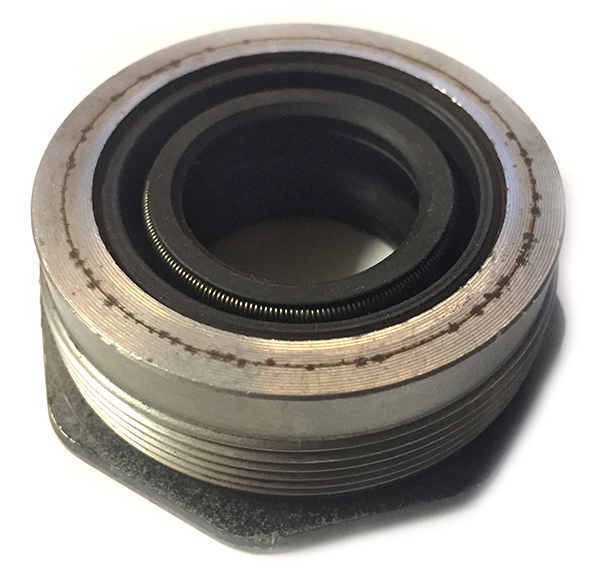

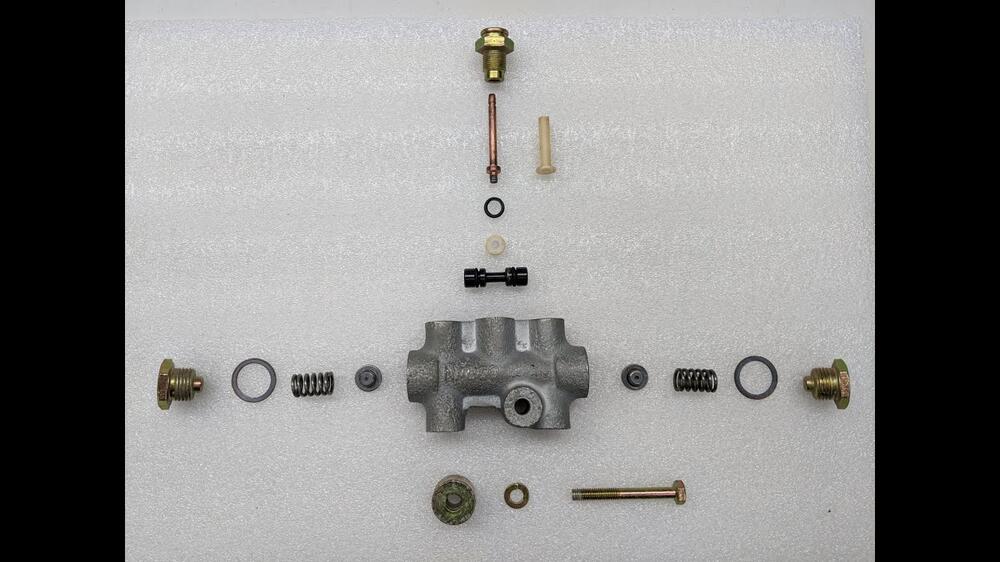

Which Gland Nut you used there doesn’t necessarily matter to what we’re trying to figure out here, but to cover all the bases, the one shown in your video is not an original Nissan 280Z Gland Nut. The original nuts had seals to keep the oil fill inside the shaft where the plunger rod was, and it would not fit down properly on top of the strut cartridge body (I was curious to see if we had an original Gland Nut here, and found one, so included images in case others wanted to see them).

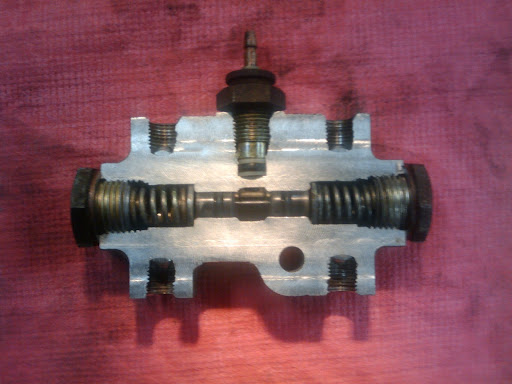

When manufacturers started making physical strut cartridges to replace the original non-cartridge setup, they all included their own specific Gland Nuts, as they needed to match the shape of the top of the strut body. Just like with Koni, that Gland Nut is the exact inverse of the top of the strut body. Depending on what strut cartridge manufacturer made that Gland Nut, it may or may not be fitting well on top of the Koni strut body; which, if not, could allow strut cartridge movement and damage.

The only way that a Gland Nut could slip when tightening would be if they somehow were incorrect nuts (difficult to imagine, but not completely impossible that some random Koni application has Gland Nuts that are nearly identical but just slightly smaller, and were mistakenly put in the box), or if the threads are damaged on one side or the other (which you said the threads weren’t), or there is damage to one part or the other (even stress/wear/cracks/stretching/damage to the strut housing tube itself).

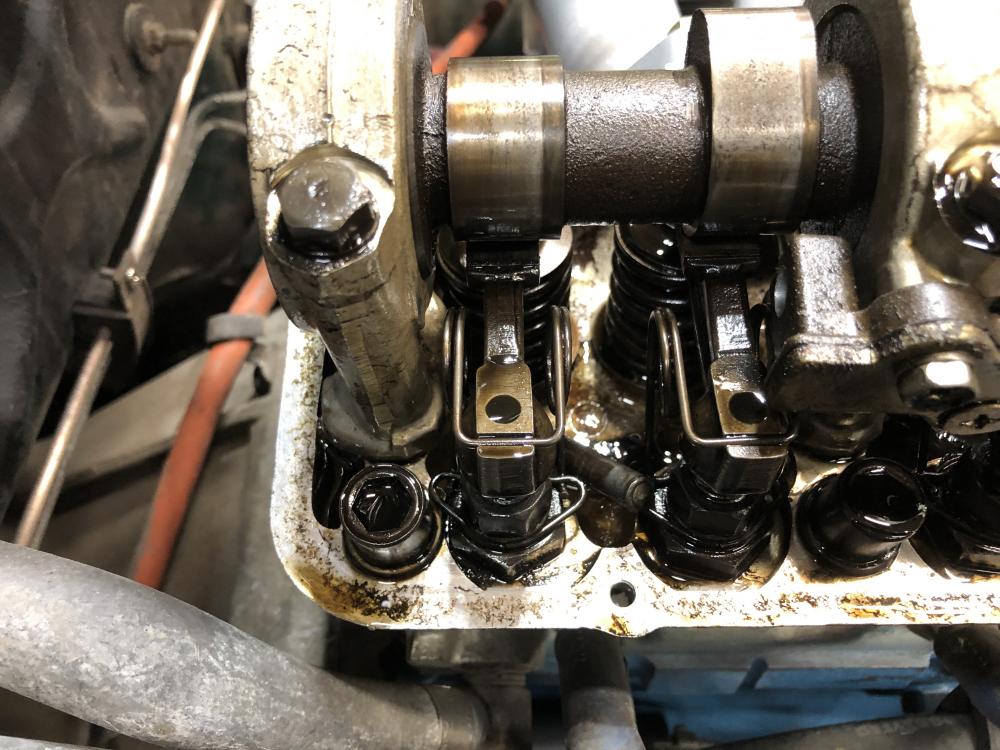

Also, in your video the top of the housing seems to be shiny clean as if machined somehow. It may not be relevant, but do you know what was done to the top of the housing tube there?

As far as the Gland Nuts you received, if you are able to measure them for us, knowing the exact dimensions and thread pitch/details would help us try to figure it out. Otherwise we could also just get those back here from you and confirm if they are correct. Since the Koni Gland Nut is the exact proper fit for the Koni Strut, then we should see what can be solved so that you can use Gland Nuts that hold the Strut Cartridge in the proper position.

Let us know.

(the first two images are of an original Nissan Gland Nut (with seal), and the third is the underside of the Koni Gland Nut shaped to fit the top of the Koni cartridge exactly)

Vendor

Vendor 4Points105Posts

4Points105Posts