Alright then. I took the head off today. The head gasket didn't stick to the block or the head, so I think it is reusable. After I got the head off, I went to work on modifying the gasket.

I used a washer with a 1/4" hole to guide the drill bit.

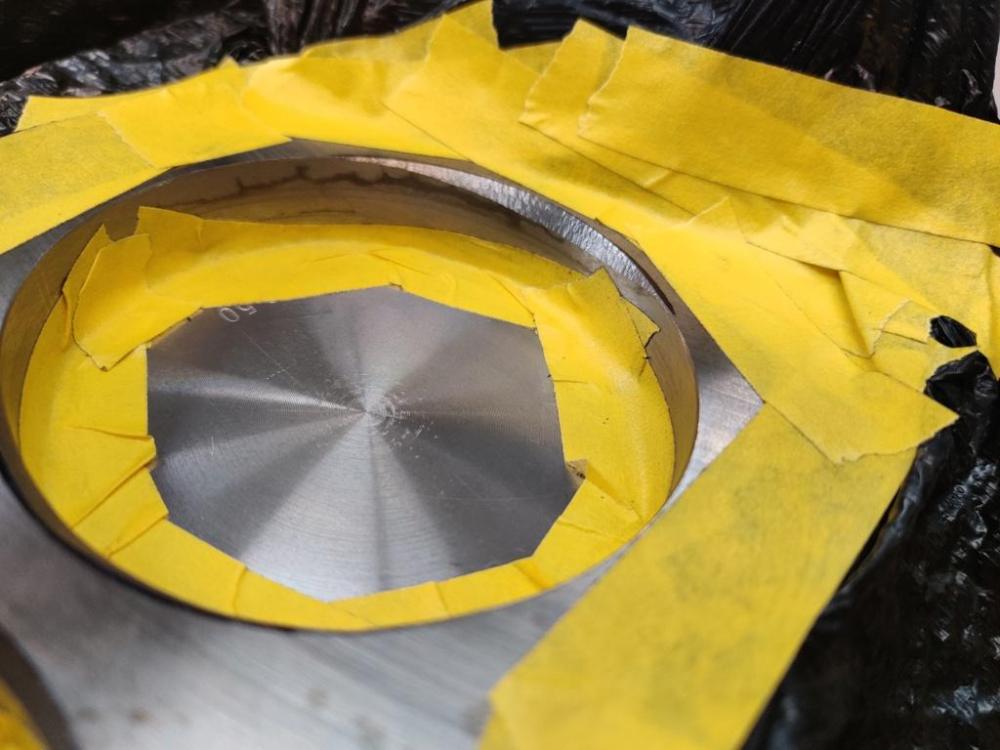

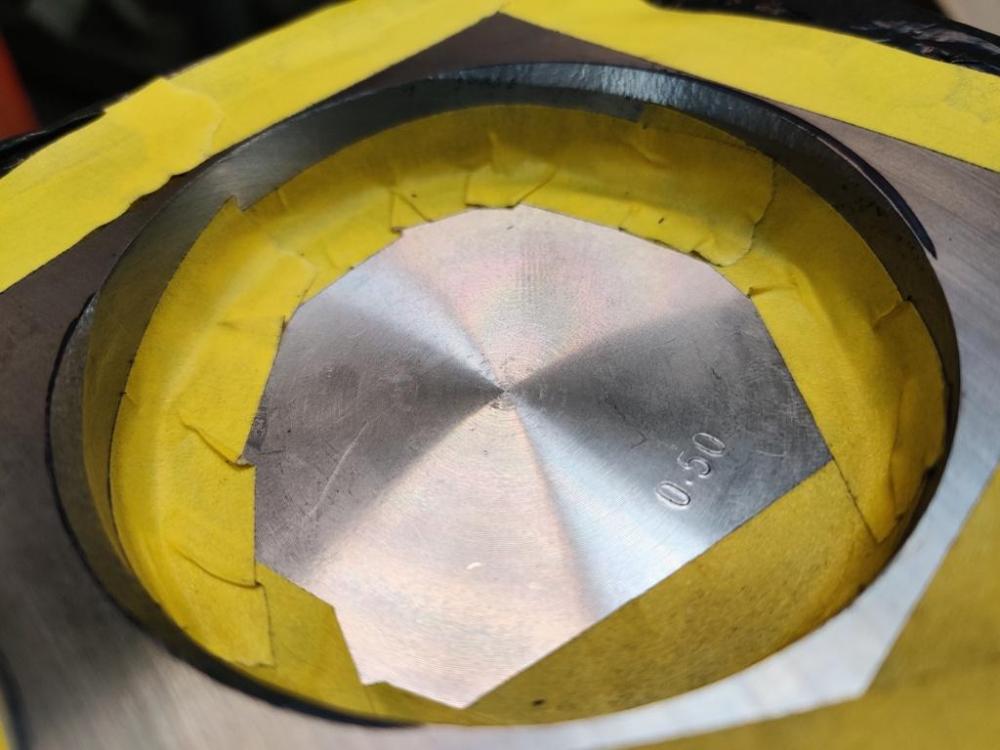

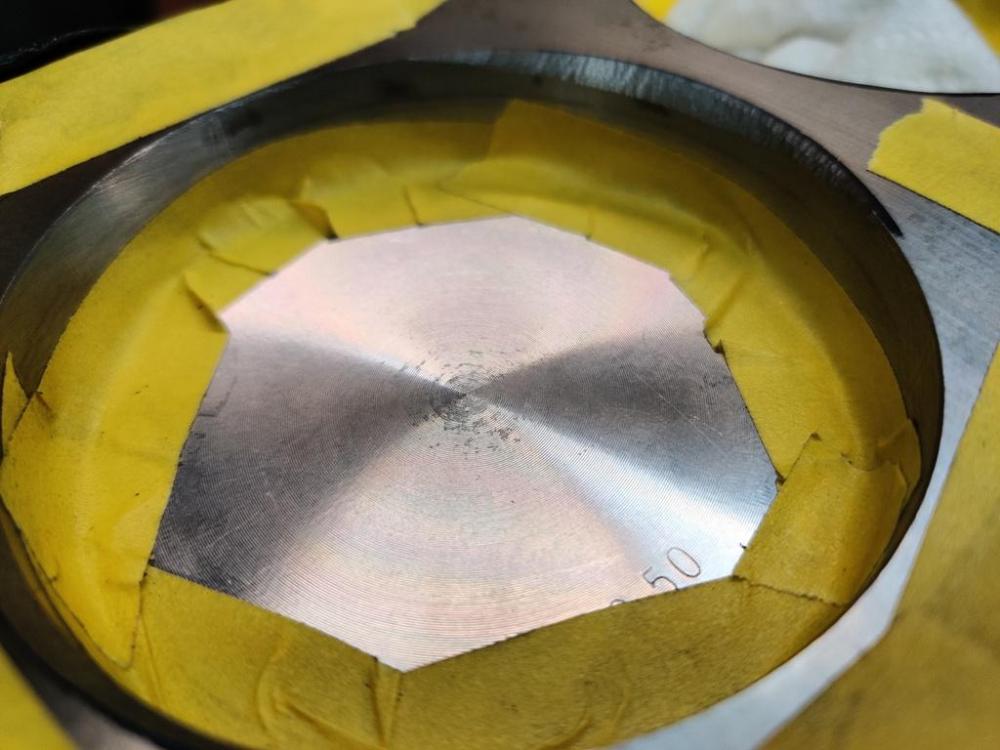

With the gasket modified, I turned my efforts on eye-browing the block. Hopefully, I have not royally screwed up here. I removed the timing chain, rotated the crank to get the pistons below deck, and then covered the block with a plastic bag, and cut out the top of it so I could access the tops of the bores.

piston 1 - pic taken from passenger side - front of piston is toward the top of the pic:

piston 2 - pic taken from passenger side - front of piston is toward the top of the pic::

piston 3 - pic taken from passenger side - front of piston is toward the top of the pic:

piston 4 - pic taken from passenger side - front of piston is toward the top of the pic:

piston 5 - pic taken from passenger side - front of piston is toward the top of the pic:

piston 6 - pic taken from passenger side - front of piston is toward the top of the pic:

piston 1 - pic taken from driver side - back of piston is toward the top of the pic:

piston 2 - pic taken from driver side - back of piston is toward the top of the pic:

piston 3 - pic taken from driver side - back of piston is toward the top of the pic:

piston 4 - pic taken from driver side - back of piston is toward the top of the pic:

piston 5 - pic taken from driver side - back of piston is toward the top of the pic:

piston 6 - pic taken from driver side - back of piston is toward the top of the pic:

A few more pics:

I did this with a die grinder and oval cutter. Tape and bag is still in place. I think I will switch over to a tapered roll and try to look for inconsistencies to address... as well as smooth the eye brows to final finish. I am well above the top ring land currently, and inside the fire ring on the head gasket as well. I was being cautious (I hope!). I will check clearances and continue - before I bolt the head on.