Everything posted by VaCat33

-

72 Brake booster

PATCON Rebuilding the brake booster cost $470 back in 2021. Re-sleeving and rebuilding a master cylinder cost $245 and that was just a month ago. Jim

-

72 Brake booster

I have used White Post several times, including a complete rebuild of the brake booster on my 72 Z. Turn around for the booster was just under a month. They also just resleeved and rebuilt the brake and clutch master cylinders on my Sunbeam Tiger. I would give them a call. Jim

- Documenting My Original Yazaki Spark Plug Leads

-

The Dreaded Vapor Lock

Hello I know it has been a while since my last post, but sometimes other things get in the way of playing with our cars. I did want to close the loop on my post. After many trials and tests we think we have the problem resolved…and IMHO it was not vapor lock, as I originally suspected. Shortly after my last post, I ran the car on a relatively cool day (mid 60s) and sure enough it died after 40 minutes and would not restart for a while. Given the mild temperature, I began to suspect some other cause, as some of you suggested. I drove the car to my mechanic’s garage. The drive is about 20 minutes. I got there without problem and left the car running. Within 15 minutes the car died. At that point we disconnected the fuel line at the carb to check the flow. Upon cranking the engine, no fuel was reaching the carb. We checked and confirmed the fuel line between the pump and carb was clear. So, we installed a new replacement (GMB brand) fuel pump. The car started and ran for 30 minutes or so and died. Again. we disconnected the fuel line at the carb…no gas. At this point we suspected a possible problem between the tank and the pump, so we ran the fuel pump inlet hose directly into a five gallon can of gas. Cranked the engine but no fuel at carb. I bought a different replacement (US Motor Works brand) fuel pump. Installed it…would not work right out of box. Ran the test with fuel pump inlet hose in can of gas. Cranked engine…no fuel at carb. We installed a used Kyosan Denki pump…the car ran flawlessly for three hours. So, I acquired a new old stock (NOS) Nikki pump. The engine has been running fine for hours at a time. Totally baffled…could these modern replacement pumps be that bad? During all these tests where we had the car running for hours, we also discovered a couple intermittent ignition issues…which may, or may not, have contributed to the original problem. Twice while running the car. it suddenly died (no stumbling…just died). A quick check revealed no spart at plugs. The first time this occurred, we had power all the way to distributor. A check of the original cap revealed the center contact was damaged and perhaps causing an intermittent problem. The second time we had no power from the coil. The resistance on the coil tested within specs but since it is a NOS coil, I suspect it might be compromised and failing at operational temperature. All seems to be working fine with new distributor cap and coil. Thanks for listening and all your help. Jim

-

The Dreaded Vapor Lock

No ethanol free gas less than an hour away. I am considering making a run, even if only for test purposes.

-

The Dreaded Vapor Lock

When I get back to testing I will give unbolting the fuel rail a try. Should be fine just idling in my driveway. Will make sure it is not touching anyplace where heat can be conducted. Looking forward to results. what confuses me…is why/how are the physics different now than in 72. This (vapor lock caused by conduction of heat through fuel rail brackets) was not a problem back in 72 and as I mentioned I owned a 72 in 72 and never had this problem. In later years vapor lock became a problem. Is modern gas that much different Re boiling point. Thanks Jim

-

The Dreaded Vapor Lock

A few comments in response to questions/comments. Fan shroud:YES Test conducted sitting in Sun, hood closed on 90+ degree day. No I did not try adding choke as engine stumbled but I will. my floats/needles were installed and set by Mike at Banzai Motorworks. My car is “bone stock” and I would like to keep it that way. When I next get a chance I intend to add fuel pressure gauge to monitor fuel pressure. Might try temporary insulation in various locations. also plan a test on a 75 degree day, see if there is any difference. Thanks Jim

-

The Dreaded Vapor Lock

Captain i put the ice packs on about 30 minutes after the engine died and would not start. I let them sit for another 30 minutes or so. Saw that temps were much lower so Tried to start but was unsuccessful. During both tests I let the car sit for a few hours…I did not track exactly how long. During the first test it started easier, but this might have been because it Sat a bit longer. in both cases it started after a couple tries. I would not say a “bunch” of cranks but 2-3 with foot to floor. First test it ran smoothly and pulled right into garage. Second test it sputtered a bit and I had to feed it gas to get it running smoothly. Hope this clarifies things. Thanks Jim

-

The Dreaded Vapor Lock

I should have added that as part of the baseline servicing performed upon acquiring this Z, I replaced the fuel pump and floats, needles and seats with those from Z Therapy. Also replaced coil, ballast resistor and plug wires (In case you are thinking ignition.) Thanks again. Jim

-

The Dreaded Vapor Lock

Hello The hot weather is here and with it comes vapor lock problems on my completely stock 1972 240Z. I have been plagued by this and it has left me stranded a couple times…at least until things cooled down. I know 73 and 74 Z’s were notorious for this problem, but I owned a 72 back in 72 and NEVER had this problem. Of course, we had ethanol free gas back then. Before we start tearing things apart and throwing parts at the problem, I decided to check temperatures around the engine compartment to see if I could nail down a likely problem area. I performed the following test on two 90 degree days. Each time the sequence of events was essentially the same. Started car and it started right up and idled smoothly to standard operating temperature At 20 minutes the engine stumbled a bit but continued to idle At 30 (test 1) and 35 (test 2) minutes the engine began to really stumble and then died I got it restarted but could not keep it running. At that point it would not restart After several hours it restarted and I was able to pull it back into the garage. While the engine was idling I took several readings and checked the temp gauge and took some temps with infrared sensor gun. At the point the engine died the Temp gauge on dash was not quite half way (front edge on M), so maybe 175 at most??? But not what I would call overheated. Temps at various locations while running Thermostat Housing 140 Temp Sender 158 Fuel Filter 120 Fuel Pump Body 107 In 118 Out 115 Fuel Rail Got a couple at 160-170 but not confident on accuracy Float Bowl (Top) Front 130 Back 126 Intake Manifold Thermostat 220 (located at the left rear on the coolant line just before it enters the intake manifold...unique to 72 models.) Coolant line between Intakes 250 I placed ice packs on fuel bowls and wrapped an ice pack around coolant line between intakes. Got the fuel bowl temp down to just over 100 and the coolant line down to 150. Tried to start it but still would not start. At the temperatures above I do not see where the fuel might be percolating, although the manifold tube and thermostat definitely seem suspicious…but no real impact on the float bowls. My next test is to place an inline fuel pressure gauge between the fuel pump outlet and the fuel rail and monitor fuel pressure as engine heats up…but I cannot get to that for a couple weeks. I know the usual fixes are to wrap insulation on fuel rail and add electric fuel pump, but before doing that I am trying to nail down the likely cause. Any other thoughts…I am all ears. Thanks, Jim

-

Nikki Fuel Pump Rebuild

Based upon foosman’s commets about replacement fuel pump quality and the experience related by Duffy in his post, I took another look at the internal parts in the replacement pump. The rubber gaskets all seemed to be a similar quality. The valves in the replacement pump were, IMHO, of lesser quality. The metal used seemed less durable and they had plastic parts. This might account for the early failure of duffy’s pump and supports what foosman stated. Luckily, The valves in the rebuild kit I bought were more like the originals. So look closely at the internal parts, especially the valves, if rebuilding your fuel pump. Hope this helps. Jim

-

Nikki Fuel Pump Rebuild

Legitimate question. All I can say is that the internal parts in the replacement pump appeared to be the same as the internals provided in the only rebuild kit that I know of. The rebuild kit cost $125…a replacement GMB pump cost $27. Individual call I guess.

-

Nikki Fuel Pump Rebuild

Rebuild completed. See attached photos. I had to find another original after stripping the threads in one of the screw holes. I used the cap from my original since it was better. Vapor blasted and then reassembled using the JDM parts rebuild kit. I got fresh inlet and outlet from a GMB replacement pump. Found some fresh correct zinc coated screws on eBay. Once things warm up, I can get it installed on car. FYI…for those of you considering this, The internals in the replacement pumps are pretty much the same as the parts you get in the rebuild kit. You can save yourself just shy of $100 by using the parts from a replacement pump. Jim

-

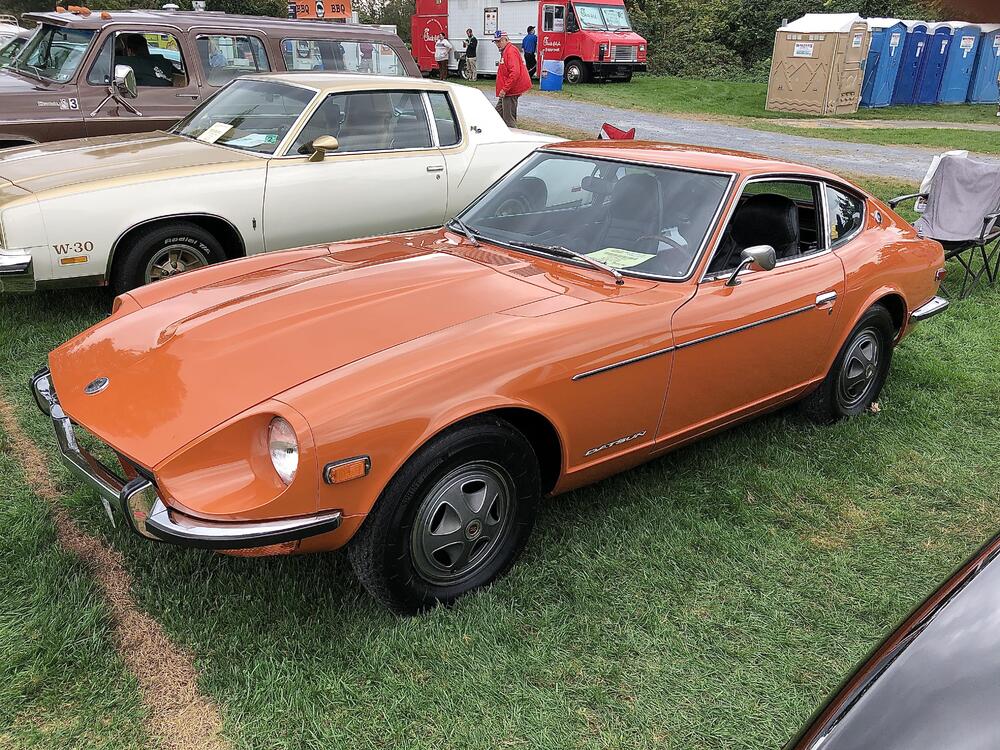

First Anniversary

Hello Let me first apologize in advance for my immodesty. It was a year ago today that I acquired my Z after winning an auction on BaT. https://bringatrailer.com/listing/1972-datsun-240z-161/ I was a bit concerned because I had never bought a car sight unseen before. Based on the comments on BaT I felt confident that I was making the right move and when the car came off the trailer my gut feeling was confirmed. The condition of this mostly original example is unbelievable. I invested some time and $$$ to make sure this car is reliable and safe in every way and operates and looks as if it just came off the showroom floor. A big thanks to Mike at Banzai Motorworks. (I hope this thank you is allowed.) In addition to some spirited driving, I made the 300-mile round trip to Hershey back in October, where the car won a AACA Historical Preservation of Original Features (HPOF) award. Overall, a good first year. Looking forward to when the weather breaks and we can hit the road again. First order of business is to address an intermittent year one problem involving stalling out when hot and difficulty restarting. I have already taken some action…new coil and resistor (thought heat might be compromising one or both) and new floats, needles/seats, tune carbs. I have enjoyed this forum and continue to do so. You have been a big help on a variety of issues. Jim 20210308_164006200_iOS.heic

-

Wanted: Nikki 271070 Fuel Pump

26th… I read that article before making my post. Was able to confirm the likelihood that my 2/72 Z was equipped with a NIkki. The article mentions some differences in the screws and cover but does not really give any definitive guidance. most of the Nikki pumps I have seen have the screws the same as the second (bottom) photo in my original post. While many I have seen have the two raised rectangular areas. Hoping somebody can provide some definitive answer. Thanks Jim

-

Wanted: Nikki 271070 Fuel Pump

A couple more quick questions about the Nikki 271070 Fuel Pump. What type screws secured the body halves and cover? I have seen two versions…standard Phillips head and a slotted screw with a cross slot similar to a Phillips but definitely different. (Sorry I do not know the name of this type screw head.) I have also seen two different type covers. One is plain other than the Nikki brand name. The other has two small rectangular raised areas. Are there different versions of the Nikki 271070 pump that might account for these differences. I have attached a couple photos showing the differences. Thanks Jim

-

Wanted: Nikki 271070 Fuel Pump

Duffy that is awesome looking. Mine is almost reassembled, but does not look as nice. Looks like you zinc plated some of the parts and screws. Is that the original finish or did you paint? Jim

-

Wanted: Nikki 271070 Fuel Pump

Of course it does. Thanks.

-

Wanted: Nikki 271070 Fuel Pump

Getting ready to reassemble my original Nikki fuel pump using the rebuild kit I acquired. The rocker arm assembly needs to be lubricated and when I first disassembled it there appeared to be some lubricating oil present in the lower body of the pump. Does anybody know what type oil is used…regular motor oil, gear oil…??? The service manual does not say anything about this, although the Haynes manual says to grease the rocker arm assembly. Thoughts? Comments? Definitive guidance? Thanks Jim

-

Wanted: Nikki 271070 Fuel Pump

Just had my Nikki fuel pump Media blasted. It looks much better, perhaps a bit dull. I will take the advice in the previous post and use some Gibbs oil based sealer. Thank You all for your help. Jim

-

Wanted: Nikki 271070 Fuel Pump

That is good scoop. I do not have ready access to a blaster…how about a Tumbler? Will that work? The VHT paint is a good fall back…in stock at my local Autozone. Thanks Jim

-

Wanted: Nikki 271070 Fuel Pump

Hello i am looking to buy a Nikki fuel pump for my 1972 240z. Part No 271070 (as seen on pump housing.) See photo. Just about any condition is acceptable. My rebuild, as discussed in my previous post, was going great. Prior to final assembly I decided to give it a good degreasing. The degreasing bath I used was much to harsh and destroyed the finish. So back to the drawing board. Now instead of the nice aluminum finish, the housing is a dull dark grey…a costly mistake. Thanks. Jim

-

Nikki Fuel Pump Rebuild

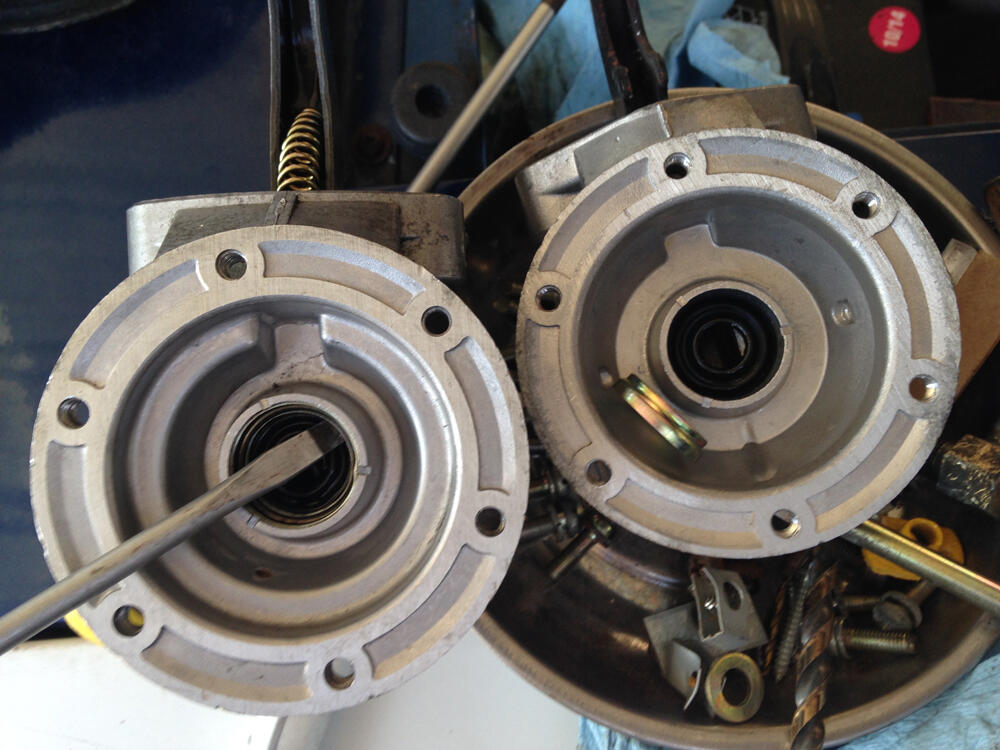

Just a brief update on the rebuild. In the original article on how to rebuild your Nikki fuel pump it discusses how to replace the rubber oil seal in the lower pump housing. As you can see in the photo, The seal went into the opening in the lower housing and was secured by a retaining ring which snapped into the opening. the rebuild kit form JDM uses a new design. The oil seal fits snuggly over the opening in the lower housing and then is secured by a retaining ring which is held in place by the pump spring. Jim

-

Nikki Fuel Pump Rebuild

Hello Again, I thought I would let everybody know That JDM parts has a rebuild kit for the Nikki 271070 fuel pump. At $125 it is not cheap. I confirmed with the company that the kit will work on all Nikki 271070 fuel pumps, regardless of the car model (as indicated in the article in the post above the 271070 pump was used in several different Datsun models.) Here is a link to the rebuild kit. https://jdm-car-parts.com/products/nikki-fuel-pump-rebuilt-kit-for-prince-ha30-fairlady-s30-skyline-gc10-with-l20-l24-engine?variant=39616128811117 Happy Holidays Jim

-

Nikki Fuel Pump Rebuild

AZ thanks. I did see this article. I am reluctant to use 50 year old rubber parts, even if from NOS unit. I was really hoping somebody out there was making a current rebuild kit. If not, I might have to consider your option. Jim