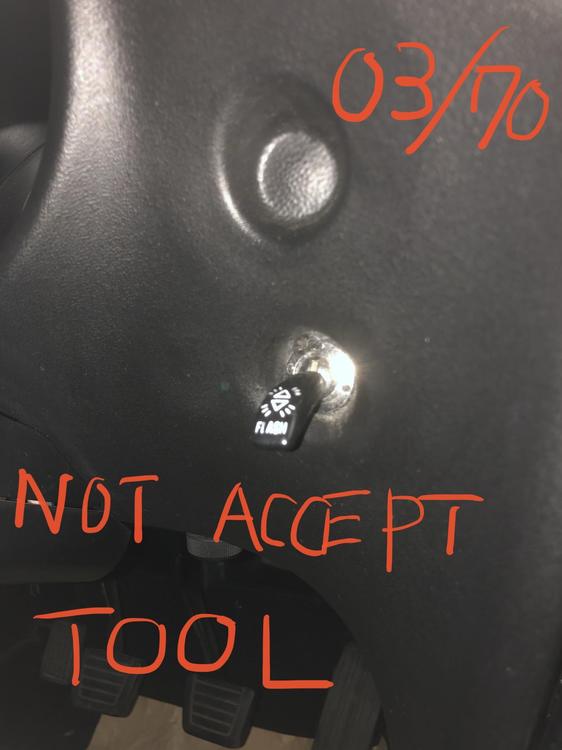

Today there is a request for hazard switches in the classified forums which leads me to go to the stash and see what I have to help.

Pawing through the group, I see plenty of differences. Of course this brings up more questions.

We know about the change to the back lit, round pull knob style switch on the North American 240's in 73, and the shorter wires on the 72 switch (6 pin connector wires), but I was surprised by a couple of differences I didn't know about. The marking on the handles vary, and most surprisingly, as does the angle of the switch's bat style handle from one to the next in either position.

All of these are the long lead variety, but there are at least three different marking styles. We likely discussed this before. I suspect the center is oldest, (one triangle), the right second oldest, and third, newest. All of the short lead switches I have share the markings of the switch on the left. All fancy and most clearly marked, must make things "better" don't we?

But what surprised me the most was the difference in handle angles in the off and on positions, comparing across all three switches.

The first pic has them all in the "ON" position, the second "OFF"

Well the handles are simply bent you say from repeated use you'd likely say. I say NOT.

Look at the thickness of the metal of the handle. It is both thick and oriented so that its rectangular cross section has the most bend resistant width in line with direction of motion. NO WAY you could bend that metal without doing damage to the switch mechanism. All switches click nicely into both on and off positions. Nothing wonky or loose inside.

Let the speculation begin!