Everything posted by SteveJ

-

two-wire hose clamps

Is this an auction that people outside Japan can use, or does it require an agent?

-

Alternator Upgrade Issue

Unless the owner has added a big stereo, the alternator won't necessarily be putting out more current than the old alternator. On the other hand the excitation curve is improved over the old alternator, so it is putting out enough at lower engine RPMs. (I know this has been mentioned in the past over at ZCar.com. I don't know if it was mentioned here.) This can make a difference with blinkers functioning properly, headlight illumination, etc. Granted, LEDs can also help with lighting performance, and I am a big proponent for them. I have used a ZX alternator in my 240Z for over 20 years without problems, and I put a Frontier alternator (70A) in my 260Z last year. It's not an accident waiting to happen.

-

Oil & Fuel guage wiring...

Finally, consider posting photos of what you're looking at. It usually easier to figure out what you are looking at if you post close-in and zoomed out photos of where you are looking.

-

Oil & Fuel guage wiring...

You can also look for the voltage signal on these wires using a multimeter if the key is in the ON position. Ground the negative probe and test the wire of interest with the positive probe. You should see the voltage fluctuate for the fuel gauge wire and for the oil pressure gauge wire.

-

Oil & Fuel guage wiring...

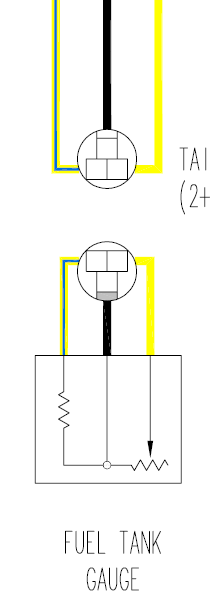

The wire back to the fuel sending unit should be yellow if the wiring hasn't been molested too badly. At the back of the car, there should also be a yellow/blue wire and a black wire. The yellow/blue wire is connected to a thermistor on the sending unit for the low fuel light. The black wire is a ground. The stock wiring for the oil pressure sensor is yellow blue. In the stock wiring, it should have a bullet or ring connector to attach to the oil pressure sender mounted in the lower middle of the block on the passenger side. The wire should go back into the wiring harness and connects to the dash harness. It in the same position for pretty much every S30 and S130.

-

Alternator Upgrade Issue

I'm saying it should be tested with everything connected. If you see voltage on the black/white wire with the key off, there is something wrong, and it's probably either a bad or incorrectly installed diode. Other than that, it could be a voltage regulator in the alternator. This is where a clamp ammeter can be handy for testing where current is flowing.

-

Alternator Upgrade Issue

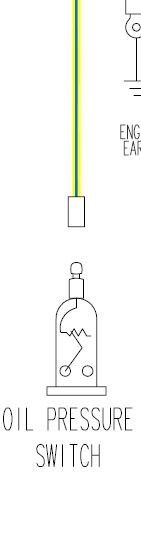

Yes, a bad diode would allow the battery to drain. This can be tested with a voltmeter. With the key off, insert the positive probe of the meter on the black/white wire (where I have the arrow). Put the negative probe on the battery negative and measure voltage. If you see battery voltage, then the diode is bad or installed improperly.

-

Alternator Upgrade Issue

Please post the year of your Z. That could provide important information. As a matter of fact, it wouldn't be a bad idea for you to create a signature with that information.

-

Now We've Done It — Broken Water Pump Bolt

If there is enough to grab, you might want to put some heat on it before you try to turn it. Again, I'll pitch the induction heater. It's easier to direct the heat than mapp gas. If there isn't enough to grab, your options are to weld a nut to it or drill a hole in the center of the bolt and use an extractor.

-

[2022] What Did You Do To/with Your Z Today?

It could have some challenges in tight spaces. However, if there is a lot of grease on the engine, it is less likely to catch it on fire. Where you can use it, it will work quickly. They have about a 2 minutes duty cycle. Here's a video where I used mine on a sway bar end link:

-

[2022] What Did You Do To/with Your Z Today?

I recommend considering the purchase of an induction heater if you think the intake manifold might be a challenge. It could help you break some of those bolts loose.

-

[2022] What Did You Do To/with Your Z Today?

Well, it wasn't exactly what I did with my Z today... I got up early today to drive over to help a new friend, Rico, diagnose his 73 240Z. He took it to a shop that may not have known what they were doing, and someone else had come over to look at his car without giving him a clear diagnosis. The car is relatively unmolested and still has the original flat tops. (That's for you, @Captain Obvious. ) I took out the plugs (fouled), and I broke out the compression gauge. The readings were 150-0-130-190-175-175. I removed the valve cover and bumped the engine to check the valve lash on cylinder 2. The exhaust was at 0.012 inches. The intake was more like 1 foot. (Okay, I didn't measure it precisely, but my 0.029 feeler cleared with room to bounce around.) Well, there's your problem. There was no way the camshaft was going to operate the valve. I tried to change the valve lash, but I wasted most of my effort trying to turn the wrong nut. (I'm SO out of practice on valve adjustments.) I did try to turn the jamb nut, but someone used about 20 ugga-duggas on it. I quit before turning the nut into a cylinder. After shooting some video and photos, I woke up a friend & long-time Z wrench (He should have been up by 10:30 AM anyway to enjoy a glorious morning. 😁) to verify it wasn't anything worse than I thought. After receiving his wise counsel, I advised Rico of a suggested course of action and buttoned up the car. It was at that point when I found the plug wires were not arranged in proper firing order. I didn't notice that when I pulled off the wires, but it was VERY obvious as I was putting them back on the plugs. I did have Rico start the car, and it idled fine. I didn't attempt to lean out the carbs since I didn't want to risk anything with the one rocker able to just about dance around. After the tools were safely back in my car, one of his neighbors asked if I might know what was wrong with his car. He said he had to pull the main fuse or else the "tail lights" would be on. So I went over and showed him how the switch on his brake pedal wasn't being actuated by the brake pedal. I love the softball questions. Here are the plugs: #1 is on the right. #6 is on the left. Here's how loose the rocker is on #2.

-

Headlight switch problem- 1978 280z

To help anyone else who is curious: https://www.leespring.com/compression-springs?search=LCM050AA02M

-

console/fuse panel help

This is a replacement box sold by MSA, but the connections are the same as stock.

-

1973 Rebuild

I'm guessing this one: https://www.amazon.com/12X12-inch-25-Inch-Thick/dp/B07GL9MHW7

-

73 Dash Replacement Project

I believe they should have connectors like the 1P (1 position) connectors on this page: https://easternbeaver.com/Main/Elec__Products/Connectors/312_Connectors/312_connectors.html

-

73 Dash Replacement Project

It also lights up the hazard switch

-

Reverse Gear Question

Take a photo of where the switch is mounted on your 5 speed. I have a truck 5 speed in my 240Z that never had a working reverse switch until last year. However, at first I didn't have it in the right location. Fortunately @Zed Head posted a great picture showing the correct location for the switch. I didn't realize there was the "top gear" switch, and that was where I was trying to connect the reverse switch.

-

tachmeter bulb replacement

I'm not sure why so many people are obsessed with that. In about 40 years of driving, I can't ever recall seeing a need to use the dimmer.

-

tachmeter bulb replacement

Thank you for confirming. While I try to find good products to substitute in for old school parts, there's a lot of opportunities for others to contribute.

-

Florida Members Roll Call

And don't forget about @Carl Beck

-

Florida Members Roll Call

I know William posted on Facebook not that long ago.

-

tachmeter bulb replacement

@kully 560, were these the bulbs you used? https://www.amazon.com/dp/B0B9MGSX7K

-

SU round tops vs dual 32/36 Webers

I had the dual Webers on my 240Z when I first bought it. Andy Craig suggested I convert to SUs when I went to him to rebuild the engine 27 years ago. I agreed and never looked back. I think I sold the Webers about 18 years ago. When you consider a member over at Zcar.com got a Z into the 12 second range on SUs (https://www.zcar.com/members/norm-the-12-sec-dual-su-dude.1912/), I don't think the SUs are holding you back too much if they are in good shape and balanced properly.

-

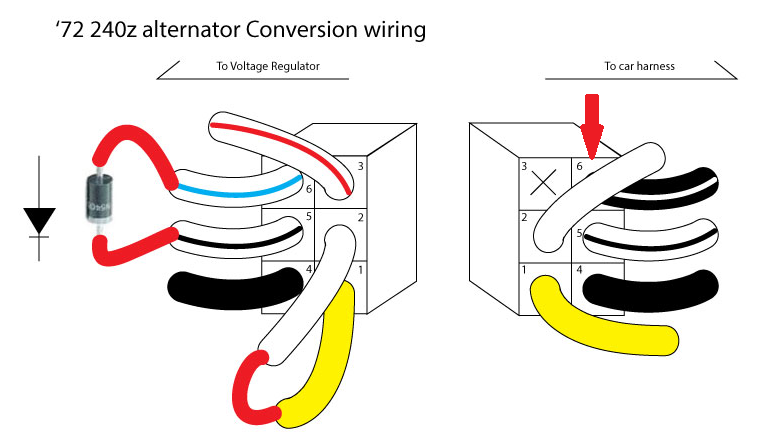

Possible replacement for 73 Intermittent Wiper Relay

I think I'm making headway. Here's a breakout of the 73 wiper wiring from the FSM. The problem is that it shows 9 wires whereas reality has 7 wires. This comes from the wiring diagram showing redundant connections for power and ground. Now that leaves other issues that I need to resolve: Is the YG wire I identified in my first post the power wire? If so, why is it coming from the engine harness? Is it connected to the wiper motor fuse? Would the wiper motor work on the washer push button without the blue wire connected? In the 73 relay, it's a power source. It appears as though it may not be needed for the Sentra relay. I guess it's about time to break out my meter.