Everything posted by SteveJ

-

77 280z Restoration

Me! Me! Me! I want to get geeky! I even started playing with the inductive pickup I bought for my scope. I really need to re-familiarize myself with working with o-scopes. It was a LONG time since collage.

-

Thinking of selling -how do I know how much my car is worth?

I should add that for top dollar, get photos underneath the car and all over the engine bay. Also take close up photos of the rust prone areas.

-

Thinking of selling -how do I know how much my car is worth?

If you have Hagerty, you can use their pricing guide. I used to think it was high, but the market caught up for the most part.

-

Heater Box Restoration

You ought to invite me up there sometime.

-

Heater Box Restoration

Here is one thread I found: Some internal photos in this thread:

-

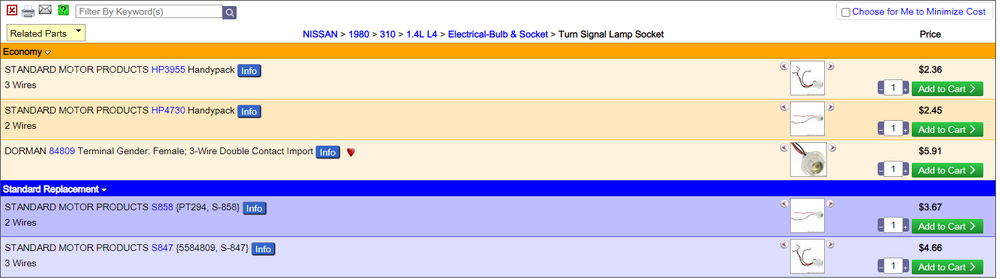

Replacement 1157 Socket

Yeah, I put some more on order from Amazon after I confirmed the fit. Looking into it more, I looked on Rockauto for the fitment of the S847 and looked at the socket part numbers for those cars. It looks like there are some alternative part numbers for the 1156 and 1157 style sockets.

-

Replacement 1157 Socket

Somewhat as a follow-up to my earlier thread: I purchased an SMP S847 socket. I tested it out in my 240Z, and it seems to fit just fine.

-

Pertronix Ignitor I won't rev - Alternative solution

That's the thing. Any of us (and that includes me) can make those little mistakes, often times not even realizing it happened. I've done things like try to start the car without the wire on the coil or with the rotor sitting on the fender. When it's not as obvious, it's easy to get frustrated and start loading the parts cannon to replace all of those bad parts that aren't really bad. In my friend's case, I could hear his frustration as he repeatedly swapped in parts with no success. That's why I went over to his place with the plan of getting a baseline and examining each part and correct each issue I encountered. This time, it was an easy solution.

-

Bleeding rear brakes

I don't think it has changed since a year ago.

-

Pertronix Ignitor I won't rev - Alternative solution

A friend installed a Pertronix Ignitor I into his 240Z, and he contacted me for help since he could cruise fine at low RPM, but whenever he tried to get on the gas, it would stumble and cough. He thought it might be a coil impedance issue so he tried various coils but kept having the same issue (and sometimes even worse performance). Since he has been wrenching on Z cars since the mid 80s, I figured he had gone down the wrong rabbit hole at some point. I loaded up the rescue wagon and headed over to his place. The first thing I did was connect an oscilloscope to see if I could pick up an obvious miss. The scope left me with the impression that something wasn't happening right as higher RPMs. (I might recreate his problem on my 240Z and see if the scope shows the same thing. If it does, I'll make a video to help people with diagnostics.) I looked at the resistance to chassis ground at the distributor. The resistance was nearly zero, so it wasn't a grounding problem. From some old threads here, I thought the vacuum advance might be an issue. Unfortunately his hand pump would let me pump up enough vacuum to check, so that was tabled. Next was inspecting the distributor cap. The contacts were clean as was the rotor. So I moved to inspecting the posts where the wires land. The wire on the center post wasn't seated far enough down, so I pushed that in. Then I pulled off each wire one by one, starting with #3 and working clockwise. It was good, #5 was good, #1 was good, #4 was good, but #2 was not. The boot was almost off the wire. There was no way it was getting a good spark. I positioned the wire properly in the boot and re-seated it. Then I checked #6. It was good. I looked at the scope again. It looked better, but I didn't shoot video. After my friend fixed a fuel leak at the banjo fitting on the rear carb, (The fitting wouldn't seal, so he replaced it.) he took it for a spin. He said there was no hesitation, and it pulled hard past 5,500 RPM. The moral of the story is that when you can't figure out what's wrong, step back and go over everything from the beginning. Sometimes you have to eliminate each and every variable until you have the solution. I love getting another Z back on the road.

-

Thermostat/Oil gauge

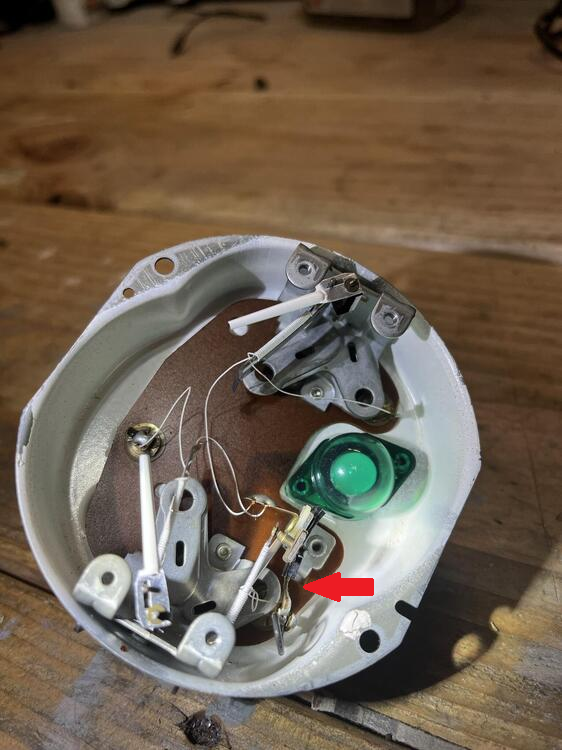

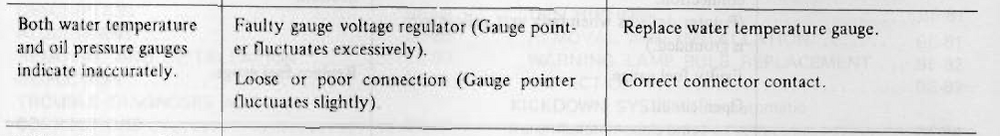

The voltage regulator is the part on the right. See the red arrow. If it's working properly, you should see it opening and closing rapidly, like you saw the ammeter needle moving in my video. As far as fix it, you would have to re-wind the coil with that fine insulated wire.

-

Seeking Exterior Windshield Molding Retainer

Reach out to Alan Poindexter at https://vintagezparts.com/ He focuses a lot on Z31s.

-

Thermostat/Oil gauge

There are places that might be able to repair/replace the voltage regulator. https://www.google.com/search?q=automotive+gauge+restoration&sxsrf=ALiCzsa7dCxxAJmczzDprB3YHBA44vbQSw%3A1663426703398&ei=j-AlY7jrF7-kqtsPhJys0Ag&oq=automotive+gauge+res&gs_lcp=Cgdnd3Mtd2l6EAEYADIFCAAQgAQyBggAEB4QFjIGCAAQHhAWMgYIABAeEBYyBggAEB4QFjIGCAAQHhAWMgYIABAeEBYyBQgAEIYDMgUIABCGAzIFCAAQhgM6DQgAEEcQ1gQQsAMQyQM6CggAEEcQ1gQQsAM6BAgAEEM6CAgAEIAEEMkDSgQIQRgASgQIRhgAUPoJWL8MYNUcaAJwAXgBgAHlAYgB0gOSAQUwLjIuMZgBAKABAcgBCMABAQ&sclient=gws-wiz ebay offerings are probably cheaper. https://www.ebay.com/sch/i.html?_from=R40&_trksid=p2380057.m570.l1313&_nkw=280Z+temperature+gauge&_sacat=0 If you go the latter route, save your gauge. Someone may want it to have one to restore later.

-

Replacement 1156 bulb socket

In my never ending quest to find parts that no one seems to be looking for, I finally found what seems to be a good replacement for the single filament (1156 style) bulb sockets for the tail lights and reverse lights. The Dorman 84808 fits snugly in the tail light housing. You can find them on Amazon and Rockauto. I'm going to get a Dorman S847 to see if it's a suitable replacement for the 1157 sockets.

-

Newbie

Probably. I'm starting to see a pattern.

- Another Vendor Is Gone

-

280Z tachometer problems with a ZX (E12-80) ignition module

No fuss, no muss, no unsightly build-up. We are glad your Z is operating normally. I would not be surprised if it drove better now.

-

280Z tachometer problems with a ZX (E12-80) ignition module

FB is good for posting pictures and getting lots of bad advice that buries the responses from the few knowledgeable people.

-

280Z tachometer problems with a ZX (E12-80) ignition module

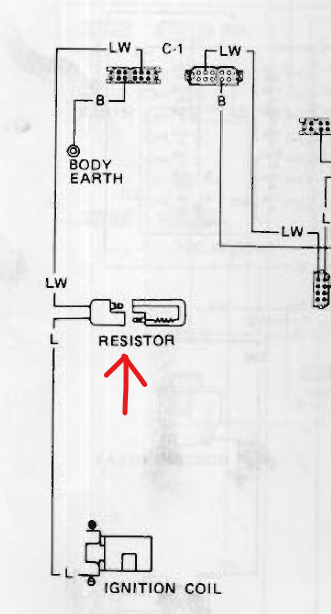

Also, here is a picture of the resistor in the passenger footwell of my 260Z. As @Zed Head said, it's taped up like a mummy. It might have different connectors in the 280Z, but this should give you an idea of what you should be looking for. It will probably be below where the engine wiring harness comes through the firewall.

-

280Z tachometer problems with a ZX (E12-80) ignition module

First he needs to take out the TIU and 10K resistor to see if he has a problem. I would not be surprised if getting rid of those (along with ensuring the stock resistor is in place) fixes his problem.

-

280Z tachometer problems with a ZX (E12-80) ignition module

Just to complete the explanation, the TIU does the same thing as the "matchbox" module on the ZX distributor. Several years ago, a friend did a ZX distributor conversion on a 260Z and brought the car to me because it wasn't running right. The first question I had was, "Did you disconnect the TIU?" After he unplugged it, the car ran like a scalded dog. Verify that the stock resistor is still in place. It should reside in the passenger footwell and plug into the wiring harness.

-

280Z tachometer problems with a ZX (E12-80) ignition module

So if you converted to a ZX distributor, why did you leave the TIU in place? It should go bye-bye. Also why did you solder in a 10K ohm resistor? The value should be 2.2K ohm if I remember correctly, though on a Google search @Zed Head gave a value of 2.3k on another thread. Double check the FSM. I know it has the value.

-

Thermostat/Oil gauge

-

Thermostat/Oil gauge

If they are both moving all back and forth, I would think it would be the voltage regulator.

-

Another Vendor Is Gone

Unfortunately, it seems to be true. The message said they stopped taking new orders as of 9/9.