Everything posted by Diseazd

-

FutoFab CV axles

Dave.....Thanks for the update on your FutoFab CV axles. I certainly can attest to the fact that I have had zero problems with mine. Also, installation was a breeze and now, if I ever need to remove them, it is a ten minute job (just remove the 6 allen head bolts and you are loose). I have no noise and with well over 200 horses at the wheels, I feel like the strength is a big improvement over the old u joints. I guess there must have been some issues with the old WolfCreek design, but as far as I’m concerned, you’ve improved the product to perfection. The only thing I would suggest is some of your torque specs seem too high for the bolt sizes.....I wouldn’t want to break a bolt. Guy

-

Cody's Goon

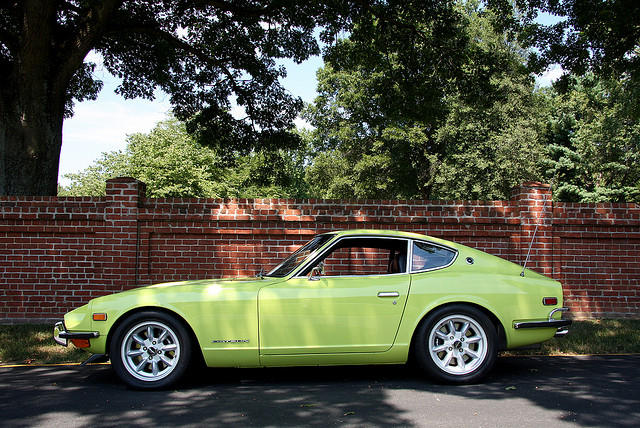

Really nice sequence Charles.........all those 70’s Datsuns are so damned cool!

-

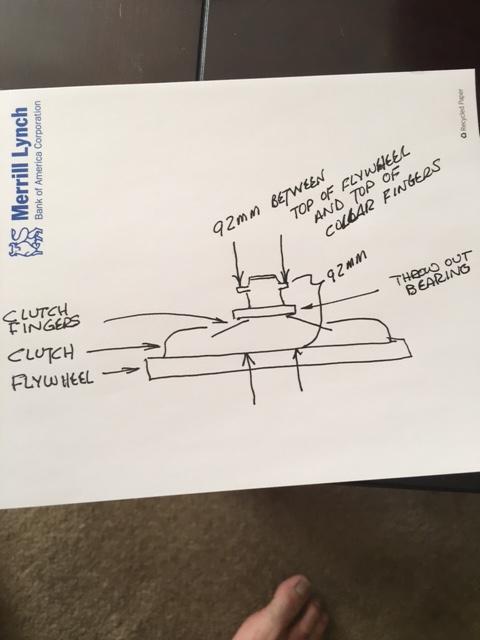

Trouble with "z" clutch...

Call Motorsports......Give them the part number of the Exedy Pressure Plate you bought. Then, tell them to send you the correct collar for that clutch. BTW......the throw out bearing is not your problem.....throwout bearings for all 240Z’s, 280Z’s and 280ZX’s are exactly the same.......seems your problem is the wrong collar....IMO.

-

Trouble with "z" clutch...

If these numbers stack up, you are good to go. Like Zed Head said.......it is probably the wrong collar.......plenty of threads on this subject.

-

Key way gone wrong

This is exactly why the 280 damper bores were machined back far enough so you could feel the groove receive the woodfuff key. If you are off just a tiny bit, it can push the key through the oil slinger. So many ways to screw up a good motor by one mistake......what a waste! BTW Capt.....you want a tight fit on your damper.....some race dampers require up to 250lbs. of torque to install.

-

Z31 N/A RB project

-

F54/P79 Swap Project

Not sure about these two questions Capt, but would assume you need longer bolts for the flywheel versus the flex plate. I am sure that you need to install the brass bushing in the rear of the crankshaft though.........the autos didn’t have that bushing installed.

-

Front Suspension Issues

-

[2019] What Did You Do To/with Your Z Today?

-

Fouling spark plugs su carbs

BTW....You don’t have to disconnect the choke cables to pop up the nozzle......literally a 3 minute fix if that’s the problem and it sounds like it is. Just stick your hand under each carb and push up the nozzle....you’ll feel it pop up if that’s the problem.

-

71 at Copart in Arlington WA

Kinda hard to believe a Cessna turbo would work on a straight six. My guess is it’s a Crown Turbo shown in the early “How to Modify” books. I always wondered how those early bolt on turbos performed. My guess is they boosted horse power and caused severe rust!!! ?

-

Fouling spark plugs su carbs

I agree with Site and Blue. You can reach under the carbs and push up on the nozzle. You’ll feel it snap back. If it is hanging up, it’ll cause very erratic idle and will blacken your plugs on those three cylinders. You’ll have to do this every time you choke the engine. Those nozzles are famous for binding when linkages aren’t aligned perfectly.

-

what's it worth?

What is it? 280Z dash and console......I would guess no matter what it is, there is easily $350.00 worth of parts!

- My Hobby BiZ

-

Z Island Gold Coin

Welcome back Will....we’ve missed you!

- Duffy's 1/71 Series 1 240z build

-

carb balance with Twinmax

I love the simplicity of my Unisyn and it seems to me if you check and double check, it is pretty darned accurate. Just my opinion.

-

918 orange Z in NH/MA area??

-

918 orange Z in NH/MA area??

She likes 918 and that’s good enough for me!

-

918 orange Z in NH/MA area??

-

Lightening of the flywheel

Well played......

-

Lightening of the flywheel

IMO, I would stick with your stock clutch with your build....nothing stronger needed. I installed a Stage I Exedy Racing clutch in one of my Stroker Motors and replaced it with a stock 240mm clutch 1000 miles later (I run stock 240mm flywheels). It was a PITA to drive in town with the Stage I. You probably shouldn’t take your flywheel much below 20 lbs. and make sure you have someone reputable do the cut. I run stock 240mm flywheels (23 lbs.) in both of my Strokers and love em. You’ll get many opinions on flywheel weights and this is my humble opinion.

-

bore out my 260 or use a 280 block?

Use a 280ZX block....bore it .040 over, use P79 flat top pistons, use the modern P79 head or N42 head (not the E88 that you have). If you go P79 head, shave and shim it .080 and install a Isky Stage III Cam. Put your numbers matching engine on a stand in the closet. Now you’ve got a fun engine!

-

300hp out of L28 non turbo

Well said Charles, but 300 hp is probably more like 20k plus....... 275C8E79-2576-48A6-8522-7995889F6CF7.MOV

-

1972 240Z Vintage Z Program Car up for Auction on BaT