Leaderboard

-

conedodger

Free Member90Points12,537Posts -

Zed Head

Free Member32Points19,240Posts -

Patcon

Subscriber

Subscriber 25Points11,143Posts

25Points11,143Posts -

zspert

Free Member22Points388Posts

Popular Content

Showing content with the highest reputation since 10/14/2025 in Posts

-

Z's on BAT and other places collection

I've been very lucky on many fronts in my life. My luck started with being born in this country and continued through being born into my family. However, for this screed I'll stick to the Z world. I started getting paid, $125.00/week, to be a mechanic at a dealer in 1970, talk about luck. I very quickly realized that paying close attention/noticing things were important aspects to becoming successful at my craft. When I opened my now closed shop in 1980 a trickle of unmodified original owner Z cars started to flow through, talk about luck. It didn't take me long to understand the importance of documenting as many details as possible. The results of my appreciation are a large stack of photos of the many fine details of 240/260/280 construction. I also have many sloppy pages of notes describing the fine points of construction and differences between model years. My goodness, I even have several pages of notes describing, in detail, the fasteners used to secure a 240 timing chain cover for production date X. Every time a serious customer approached me for a restoration I would ask, in detail, exactly what he/she wanted the finished product to look like. Before they had a chance to answer I would describe what an original Z looked like from the factory and I'd often show them a few pictures from my collection. The answer was always not just no but HELL NO! They wanted pretty. What does pretty mean? Modern, often 2 stage, paint that has been wet sanded and buffed to near perfection. Powder coated suspension and all the other bits and pieces of modern restoration required to satisfy a customer. To see 2 of my last 3 Z car restorations visit my site and click on Customer Profiles. When a 240 left the factory there was orange peel in the paint in random places. Have to mention that this particular problem improved markedly in about 1975 or so. However, there was often a serious problem with the clear coat discoloring when 2 stage paint was used starting about the same time. The paint on the bottom was applied very unevenly and often contained dirt in random places. Most of the grommets that were glued in place had glue running down from the grommet. The suspension pieces were painted a sloppy and uneven satin black. There was overspray on some of the exterior engine components that were in proximity to the engine block. The list goes on from there. Please don't misunderstand me, I'm not criticizing Datsun, that was the way cars were often manufactured back in the Olden Days. I can all but guarantee that if a real factory-like restored Z showed up at a convention a trophy would not be forth coming. Now to address the hyperbole that has crept into the world of Z restoration. "Frame -off Restoration", "Rotisserie Restoration", "Factory Restoration", etc., etc., etc. There are some new ones now like "Magnificent" and so forth. The situation is often made worse with fancy photography and lighting. This is what happens when marketing geniuses get involved. Remember the Z Store Program? H@#$, now I'm often confused and don't understand what they're talking about. ALWAYS look at the car you're considering or send someone like me to have a look before making that offer. I understand that I've only lightly covered this subject but there you have it for better or worse.8 points

-

240 with e12-80 plug gap

7 pointsI'm taking a year off from life. 99% of the bad ones are from pushing to fast to get back to work. Not me, I enjoy being at home.7 points

-

Float level advice, please.

5 pointsI'm a big fan of having a vacuum gauge on the balance tube (and plugging the emmissions holes). If the engine isn't healthy, it doesn't matter how the carbs are tuned. Compression, Timing, then Carbs. The vaccum gauge is a wonderful tool to see the health of the engine. I5 points

-

Told him to scrap it !

5 points

-

1971 HLS30-14938 "Lily" build

4 points'Make damn sure your sparks are right before you start messing around with the fuel'. Butch Bohunk, Master Mechanic, Finzio's Sincair Service4 points

-

280zx 1979 2+2 slick roof restauration

Hi guys, this week i sold my 240z! It needed a good service as the engine leaked some oil, the body needed some work and.. i don't have the energy to work on it i will now concentrate on the engineroom of the 280zx i had restored in the past years.. I kept my self made mahogany steeringwheel and gave the new owner the rear wheel arches that i had stored on my attic with the car and some other nice parts to make an nice driver car for every day. As you can see in this pic the car has glassfiber rear arches and they are not original. As i said, i will now with some help of a friend, going to work on my almost ready 280zx! He also helped to get the lighting ready in my carport as he is a electrician as i am also! I finished also the air to air heat pump in my garage, so we can work on the 280zx coming winter. It was a bit difficult to let the 240z go but i had it for 27 years, and drove it for 25 years! It was a blast!4 points

-

Z's on BAT and other places collection

In Brief: Paul Taylor is the person that bought HLS30 02545 from Bill Reagan, the person that restored HLS30 02545. Paul then took his Datsun 240Z to a Z Car Club Association (ZCCA) annual convention. There I believe it caught the attention of a company that produced/sold fairly high end Die Cast Models: The Franklin Mint. They talked Paul into allowing them to use his 240Z as the model - for their Die Cast model. Thus it became the Franklin Mint Model. At issue AIR they sold a limited edition for ??? $125.00… Paul’s Z was also invited to the Automobile Hall of Fame’s Ceremony of Mr. Kayatama being inducted to the US Automobile Hall of Fame. Because of #02545 documented history, full restoration and association with Mr. K and the Franklin Mint’s model - It has become a very desirable Collector item.4 points

-

SN 00042 Restoration; The Older Twin

4 pointsThis is the Jet Hot cast finish. Please excuse the slightly green cast which is the result of either lighting or camera user error. I like the color but more importantly it's extremely robust. After more than 25 years the exhaust manifold on my 280 still looks like it was just done. Hope this helps. Not a job one wants to do twice. PS This is the exhaust manifold from the Z used as the model for the Franklin Mint Z car4 points

-

Duffy's 1/71 Series 1 240z build

4 points

-

1971 HLS30-14938 "Lily" build

4 pointsI got back in the shop today. Rear bumper is on. I don't like the fit but it's on for now... License plate light and hatch badges and I think the rear end is done Also worked on installing the leather pieces over the wheel arches I trimmed one of the last pieces and hemmed it with glue4 points

-

1973 Rebuild

4 pointsOh.. Americans with theire abriviations... 🙃 LET'S FIND OUT.... ;-) I took a run after reading a few lines... do you too? 😄 (From acronymmap.com) When it comes to quirky acronyms, SWMBO is one of the more humorous and culturally loaded ones. Short for “She Who Must Be Obeyed,” it originated from the 1886 novel She by H. Rider Haggard and was later popularized in British pop culture, especially by the TV series Rumpole of the Bailey. In modern usage, SWMBO is often a tongue-in-cheek way to refer to a wife, partner, or authoritative woman—sometimes with affection, sometimes with sarcasm. It’s playful, but depending on the context, it can also carry undertones of reverence, exasperation, or humor. But what if you want a different way to express a similar dynamic—whether you’re writing fiction, creating dialogue, or just having fun with words? Here are 30 alternatives to the “SWMBO acronym,” each offering its own spin on authority, affection, or dominance in relationships, with tips on when to use them. 💬" src="https://s.w.org/images/core/emoji/16.0.1/svg/1f4ac.svg" style="box-sizing: border-box; vertical-align: -0.1em !important; border: none !important; max-width: 100%; height: 1em !important; display: inline !important; box-shadow: none !important; width: 1em !important; margin: 0px 0.07em !important; background: none !important; padding: 0px !important;"> 30 Alternatives to the “SWMBO Acronym”1. The BossMeaning: The one in charge—clearly or unofficially. Example: I’ll have to check with the boss before making plans. When to use: Light and common; works in everyday banter. 2. WifeyMeaning: Slang term for wife or partner, often affectionate. Example: Wifey said no more late-night snacks. When to use: Casual and endearing tone. 3. Her HighnessMeaning: A mock-royal title, playful yet deferential. Example: Her Highness demanded sushi tonight. When to use: Use humorously for high-maintenance behavior. 4. Queen BeeMeaning: The dominant female in a social setting. Example: At every family event, she’s the queen bee. When to use: Playful or slightly sassy tone. 5. The MissusMeaning: Informal British term for wife. Example: The missus wants the lawn mowed by noon. When to use: British-style humor or traditional tone. 6. Lady of the HouseMeaning: The woman in charge at home. Example: I’ll have to run it by the lady of the house. When to use: Respectful, classic tone. 7. My Better HalfMeaning: Affectionate term for a spouse. Example: My better half thinks I should eat more greens. When to use: Loving and respectful, ideal for couples. 8. She-Who-DecidesMeaning: Humorous variation of SWMBO. Example: She-Who-Decides has spoken—no takeout tonight. When to use: Playful and sarcastic tone. 9. Commander-in-ChiefMeaning: The ultimate authority, especially in decisions. Example: She’s the commander-in-chief of our calendar. When to use: Family, logistics, or decision-making jokes. 10. Madam PresidentMeaning: Feminine version of a powerful leader. Example: Madam President vetoed the weekend trip. When to use: Great for dramatic flair or political puns. 11. House CEOMeaning: The domestic leader. Example: The House CEO says we’re budgeting this month. When to use: Modern, corporate spin on household dynamics. 12. Home MinisterMeaning: Borrowed from political jargon; leader of domestic affairs. Example: The Home Minister says we’re painting the kitchen. When to use: Popular in South Asian or formal humor. 13. She-Who-Knows-AllMeaning: Exaggeratedly wise or all-knowing woman. Example: Let me check with She-Who-Knows-All about dinner. When to use: Good for light sarcasm and praise. 14. The Decision MakerMeaning: The one with the final say. Example: The Decision Maker chose Italian tonight. When to use: Straightforward and respectful tone. 15. Supreme RulerMeaning: Absolute authority figure. Example: Our Supreme Ruler has declared Sunday a rest day. When to use: Dramatic or theatrical humor. 16. The Real BossMeaning: Implies there’s a “fake” boss—you! Example: You know I’m just the assistant; she’s the real boss. When to use: Self-deprecating humor. 17. Lady SupremeMeaning: Formal and elegant version of a leader. Example: Lady Supreme prefers red wine, not white. When to use: Elevated, stylish tone. 18. Chief Home OfficerMeaning: A modern acronym-style twist. Example: The Chief Home Officer rejected my couch pick. When to use: Satirical or millennial context. 19. She-Who-ChoosesMeaning: Authority over all decisions. Example: She-Who-Chooses has picked the movie already. When to use: Fun for everyday decision contexts. 20. Life ManagerMeaning: Handles schedules, meals, and logistics. Example: My life manager says we’re booked Saturday. When to use: Modern, respectful tone. 21. She-in-ChargeMeaning: Simple, direct way to show authority. Example: She-in-Charge just changed the plans. When to use: Works in light banter or social media captions. 22. The OracleMeaning: Source of wisdom and prediction. Example: The Oracle says the weather’s too cold for shorts. When to use: When referencing judgment or intuition. 23. The GeneralMeaning: Authority with a military-like tone. Example: The General has scheduled laundry drills for Sunday. When to use: Humorous, structured or “bossy” tone. 24. The PlannerMeaning: Coordinates everything. Example: The Planner already booked the holiday tickets. When to use: Useful for lifestyle or family writing. 25. Queen of EverythingMeaning: All-encompassing authority. Example: As the Queen of Everything, she makes the rules. When to use: Sassy, confident characters or real-life queens. 26. Her Royal HighnessMeaning: Majestic and a bit dramatic. Example: Her Royal Highness refuses to eat leftovers. When to use: Fun and theatrical tone. 27. Operations ChiefMeaning: Runs the day-to-day. Example: The Operations Chief set curfew at 10 PM. When to use: Use for modern or workplace metaphors. 28. Lady LogicMeaning: Appeals to reasoning and planning. Example: Lady Logic said buying a third toaster isn’t smart. When to use: Clever, witty banter. 29. Mood ManagerMeaning: Controls the emotional climate. Example: When Mood Manager’s happy, we all win. When to use: Emotional tone regulation or family jokes. 30. She-Who-Must-Not-Be-IgnoredMeaning: A dramatic twist on the original SWMBO. Example: Trust me—you don’t ignore She-Who-Must-Not-Be-Ignored. When to use: Strong-willed or high-stakes situations, humorously. > How to Choose the Right WordWhen choosing your SWMBO-style alternative, ask yourself: Is the tone playful, romantic, or sarcastic? Go with Wifey or She-Who-Decides for affection, Supreme Ruler or Her Highness for sass. Are you in a professional, creative, or casual setting? Use House CEO or Home Minister in clever writing. Stick to The Boss in casual conversation. Do you want to sound respectful or silly? My Better Half and Lady of the House are gentler, while The General or Queen of Everything lean toward satire. Is it cultural? Home Minister resonates well in South Asian families; The Missus fits UK usage. > Final ThoughtsLanguage lets us show affection, sarcasm, and social dynamics all at once. Acronyms like SWMBO are fun because they capture complex relationships with humor and punch. But with the right alternatives, you can adapt the tone, show respect, or even poke fun—all while keeping it creative. So next time you’re writing a caption, penning dialogue, or teasing your partner, try out one of these 30 creative expressions. Let your vocabulary reflect the fun, fiery, or fabulous dynamics of the powerful women in your life.4 points

-

Float level advice, please.

4 pointsStill waiting for the silicon rubber fuel lines, but in the meantime disconnected the fuel filter and took a container with new fuel, connected to the fuel rail. I made sure to purge the questionable fuel. Cranked the engine, coughed and sputtered and the engine actually started. It was running extremely rough, couldn't even tell if it was all cylinders. Once I cleaned up some spilled fuel on the ground, I'll try again. The fuel level is set to 10 turns (10mm) below the bridge. I then set the nuts on the nozzles to 2.5 turns out from the bridge. I should pull the plugs just to see what they look like, hasn't been running in probably 5-10 years. As the engine ran, I could even hear the electric fuel pump running, thus fuel on the ground. I'm going to connect the fuel system back to kind of normal, where it will suck clean fuel from a gas can, as the tank is dirty. I also need to put some 20 weight or atf in the carbs, think I've used too heavy oil. I didn't have the engine running long enough to experiment with mixtures yet. I'll keep you posted, not out of the woods yet. Jim4 points

-

SN 00042 Restoration; The Older Twin

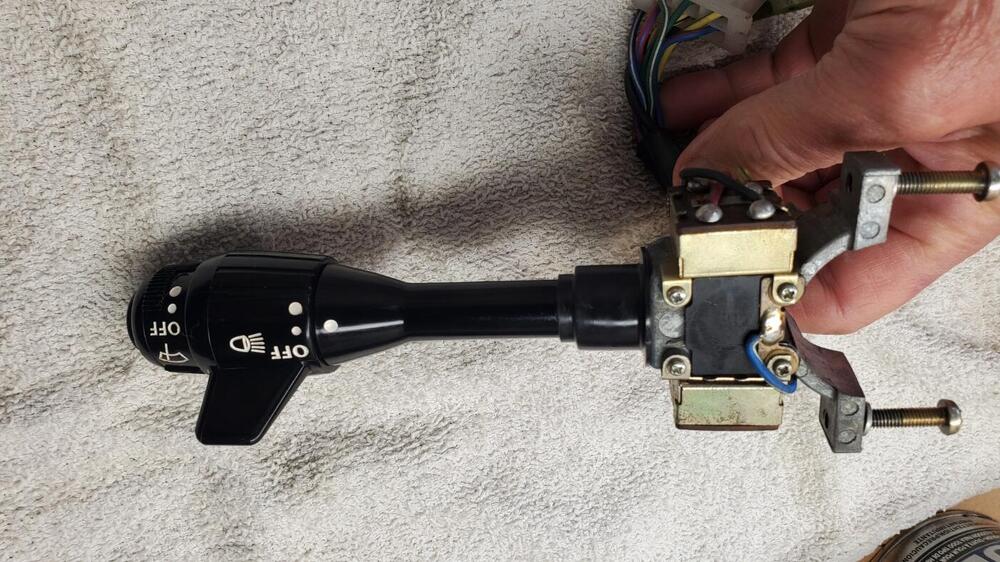

4 pointsThe body shop work continues and looks like things are moving along nicely. I am happy to see that they are being very thorough and even cleaning up areas that no one will ever see. I did check the seat mount locations. The rear inboard bracket on both the drivers and passengers side is off by about 2 inches (both are too far outboard). Carlos has a welder and will do the re-mounting of the bracket. I did contact Larry, the original metal work guy, to point out the error. Looks like we will get that re-mounted for no additional cost. I also sent pics of the dimesnions from the seat rails. The dimensions that I measure are 13.0" wide (330mm) and 12.75" deep (324mm). I removed the air galley from the exhaust manifold, but was not able to salvage it. After repeated heating, cooling and lube applications, I was only able to get 2 of the fittings out. By this time, the hex portion of the remaining fittings were starting to get pretty trashed, so I ended up cutting the tubes on the remaining 4. Fortunately, I did not have to do any re-tapping of the four difficult fittings. I was able to drill away most of the metal in the center of the fittings and sort of peel the threads off of the manifold. This made is easy to save the extension tubes that are secured by the fittings. On all of the previous cars that I have restored, I have always used a gray powder coat finish on the exhaust manifold that Les Cannady at Classic Datsun Motorsports always uses. Since we want to be very exact on the reproduction, I was considering a high temp cast iron paint which would be closer to the original color. However, it was noted that those typically peel even with the best prep and application. POR 15 was recommended, but again, this ends up being a colored paint and softens the texture of the original cast iron and doesn't really replicate the original color. I eventually phoned Rod Schmitt of Rod's Garage (Restorer of the 2025 JCCS Best of Show Red 240Z and John Morton's 1st place Green 240Z in the 240Z category) to find out what he uses for the final finish on the exhaust manifold. Rod says he cleans the manifold well with wire wheel and then uses a couple light coats of graphite spray for the final finish. He says this comes the closest to the original color and finish. It also handles the high temps well. So, this is the current plan for the exhaust manifold finish. I have started cleaning up some of the steering column parts. Some before and after pics are attached. It looks like these components have been accessed previously as the turn signal mechanism had a wire that was just twisted together with an extension on the horn circuit, so I removed the extension and soldered the wire in place. It has a broken connector which I thought I could replace with another signal mechanism that I have but that replacement was just as brittle as the broken coneector, so I just ordered a new one. Also, the headlight mechanism looks surprisingly good, so I am thinking that may have been replaced as it looks virtually brand new. Typically, these are pretty gummed up and the white parts are yellowed and/or dirty. This one looks untouched. I will re-restore the steering wheel as the previous restoration is poor. The black paint is thick and uneven and should be a satin finish, not gloss. The 'wood grain' portion has a heavy gloss finish, should be light satin or semi-gloss, and the back side with the 'nubs' was over sanded so the wood grain appearance is missing on the nubs.4 points

-

Door dovetails

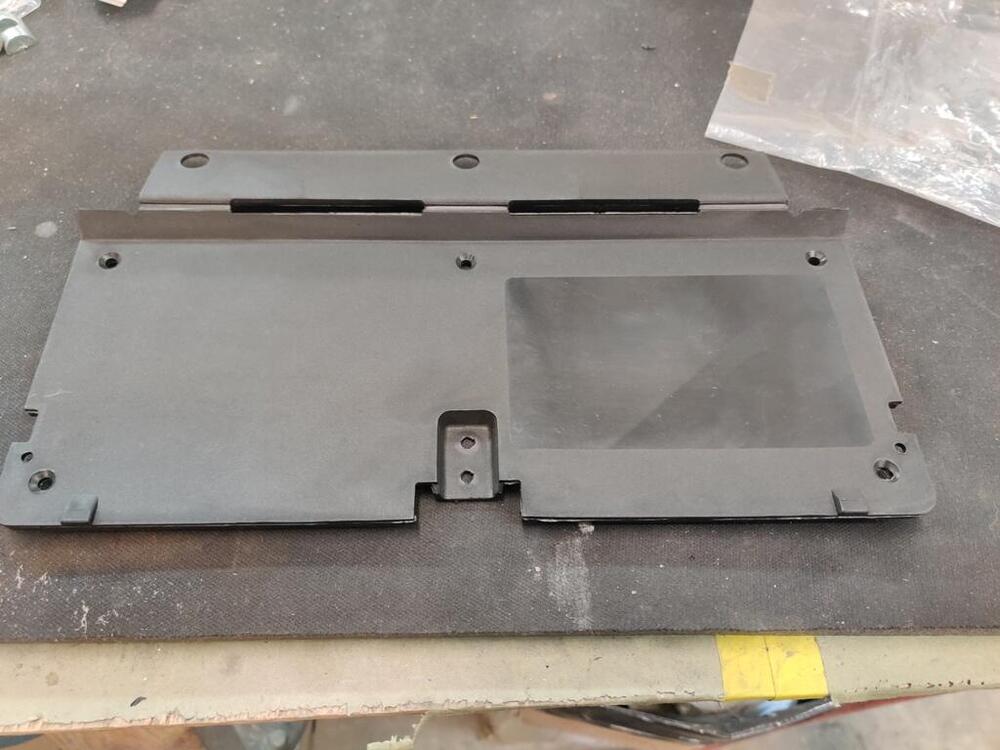

4 pointsThe early 240Z had handed dove tails for the doors, a left and right sided fitting were required. Part numbers R 80530-E4101 and L 80531-E4101. https://www.carpartsmanual.com/datsun/Z-1969-1978/body-240z/body-side-trim-side-window/62 On later cars there were replaced with a symmetrical part that fit on either side. 80530-N3400 Biggest problems with the early ones were the tabs where the screws went through breaking off. Replacement factory parts haven't been available for years. Fortunately I have a set of unbroken originals which we modelled up and reproduced in aluminum. We added an extra 1mm around the screw holes to prevent the cracking and breaking. Just picked up the first samples to fit check and they work just like the originals. The original one is on the right, you can see the slight increase in thickness around the screw holes on the left one. Also modelled up and replicated the original plastic grease reservoir for the steering rack. I'll post details in a separate thread.4 points

-

saturday night music thread

4 points

-

79 280z Brake Problem

3 pointsUpdate. It's been several months when I posted questions about a soft feeling brake pedal in my 79 zx. I checked the vacuun check valve and found it to be defective. I didn't even use my vacuum test equipment but instead just removed it and blew and sucked through it and knew it wasn't holding vacuum. I replaced it and now have very good, stock brakes again.3 points

-

For @yarb. This doesn’t concern you guys who aren’t in florida

3 points

-

What does this do?

3 pointsI plugged mine off but it doesn't get very cold down here. Less chances off leaking, losing coolant was my main reason. Lots of info in these threads... https://www.google.com/search?q=plugging+water+to+carbs+240z+classiczcars.com&sca_esv=77dc914585b7f4b2&rlz=1C1VDKB_enUS1121US1121&ei=1oETafjINaKHp84P-LudoAw&ved=0ahUKEwj4i8S_3uqQAxWiw8kDHfhdB8QQ4dUDCBM&oq=plugging+water+to+carbs+240z+classiczcars.com&gs_lp=Egxnd3Mtd2l6LXNlcnAiLXBsdWdnaW5nIHdhdGVyIHRvIGNhcmJzIDI0MHogY2xhc3NpY3pjYXJzLmNvbTIFEAAY7wUyCBAAGKIEGIkFMgUQABjvBTIIEAAYgAQYogQyBRAAGO8FSJZBUOkFWKcfcAF4AJABAJgBlgGgAcYIqgEDMC45uAEMyAEA-AEBmAIKoALsCMICDhAAGIAEGLADGIYDGIoFwgILEAAYsAMYogQYiQXCAggQABiwAxjvBcICCxAAGIAEGLADGKIEwgIKECEYoAEYwwQYCsICCBAhGKABGMMEmAMAiAYBkAYIkgcDMS45oAfSHLIHAzAuObgH5wjCBwUwLjguMsgHFA&sclient=gws-wiz-serp3 points

-

280zx 1979 2+2 slick roof restauration

Should have put it on BaT so we could pick it apart!3 points

-

1971 HLS30-14938 "Lily" build

3 pointsMy vote is that electronic distributer. Do you have an old points style one you could swap back to ?3 points

-

Z's on BAT and other places collection

3 points

-

1971 HLS30-14938 "Lily" build

3 pointsSo Cody and I got the tachometer working tonight. Big thanks to @cgsheen1 Chuck. His explanation for current flow to the tach and back made it all make sense. I took the tip of my thumb off with a hammer tonight in the shop, so I didn't get the last piece of leather in. Opposable thumbs are really useful, as it turns out.3 points

-

Float level advice, please.

3 pointsI just ordered a pair from Z, I've used silicon rubber hoses before for other gas-related things, they would eventually get soft, but I'm told their's is made for gasoline. I'll do a visual again, looking for vacuum leaks can be difficult, if the engine was running one can use propane that gets sucked up from the leaks and you can hear it in the engine, but this guy won't start yet, oh forgot, need to use new fuel to be supplied directly to the fuel bowls. I'll keep you posted, hopefully getting close. Jim3 points

-

Z's on BAT and other places collection

WOW! My 6 letter comment that could have meant a host of different things was almost immediately taken by our resident grouch as an insult or slight that I had directed towards another member of this forum. I've had a relationship with Chris for many years and have done business with him on numerous occasions. Before Covid I was to have traveled to The Netherlands on his dime to inspect his collection and offer suggestions. I've always found him to be a gentleman on all levels who is apparently having a problem with lost/missing paperwork. I wish him all the best. While I may be a greasy and now rather ancient mechanic who doesn't know his a@$ from a hole in the ground I've learned a bit about human nature after dealing with the public for the past 45+ years. There are some people who are just plain unhappy. This unhappiness is manifest through insults, cursing, almost consent contradiction, just plain difficulty/impossibility to deal with or all of the above. While my shop was open I had to deal with these types. Thank goodness they were few and far between. From this date and time I will no longer comment on or address ANY missives from the individual in question.3 points

-

240 with e12-80 plug gap

3 points

-

240z air inlets

3 pointsBetter question is what is that carb for... Sorry, no love for those with me.3 points

-

Door dovetails

3 pointsI'm happy with how the dove tails turned out so I'll go ahead and have a batch made up if anyone needs them for a restoration. Just sourcing the right JIS screws.3 points

-

Dome lamp repair

3 points3 points

-

Dome lamp repair

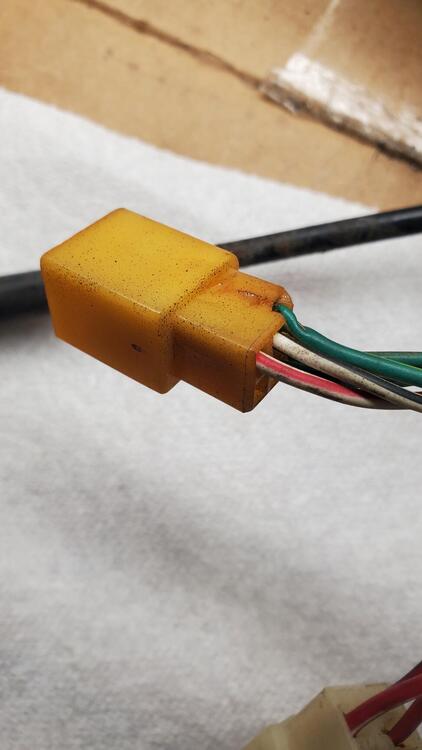

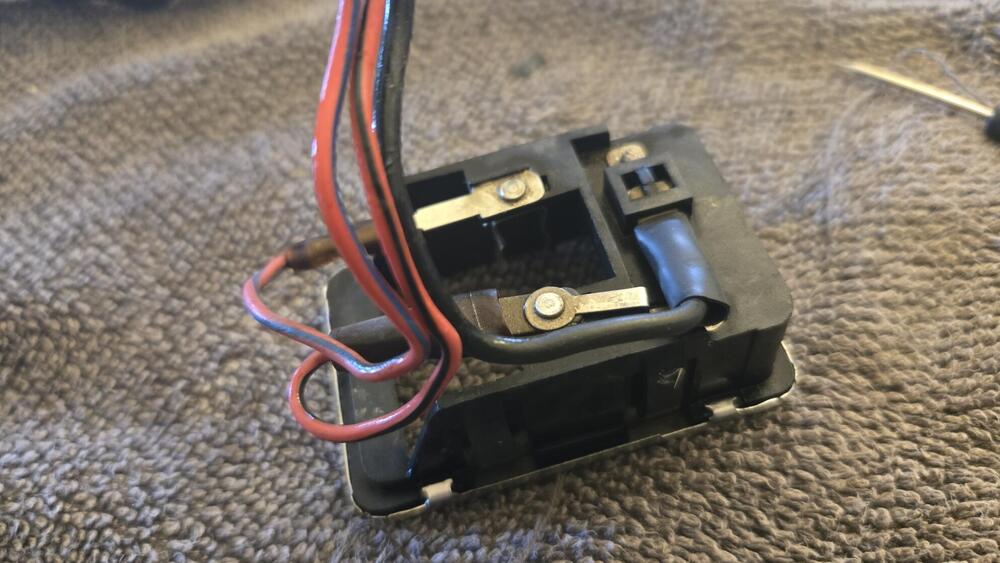

3 pointsHere is how this one was wired: Main GND (B) is a male spade that pushes into a female held in that little box. Red/Black (RB) is the GND from the door switches. Red/Blue (RL) is +12V from the fuse box. And they're both female spades. You'll notice that the main GND can be interrupted by the switch and that the RB GND from the doors is independent of the dome switch. Now. To refurbish this one AND try putting it back together - so that it still works...3 points

-

Not secure

3 pointsThere's no security problem and a chat bot has not taken over the site. lol Our SSL certificate expired the other day and was renewed within an hour. Basically, cert services can no longer offer automatic certificate renewals and must be manually renewed by yours truly. Our website runs all pages through secure (HTTPS) so none of your data can be viewed by a man in the middle. It takes manual intervention to keep a site like this online. :)3 points

-

Resurrected Classics Exhaust

2 pointsI am well pleased with the MSA Ceramic Coated Header and Premium Exhaust System I installed some 14 years ago. The fitment was spot on, the OE heat shield fit without bending or mods, no interference with the steering rod or frame rails. The supplied Turbo muffler was a bit loud and had some drone at 3k RPM, a 12" resonator I later installed cured that and softened the sound a bit. A local shop I use was very impressed with the overall design and exceptional quality of the entire system.2 points

-

saturday night music thread

2 points2 points

- Restoration of BringaTrailer 240z - HLS30-35883

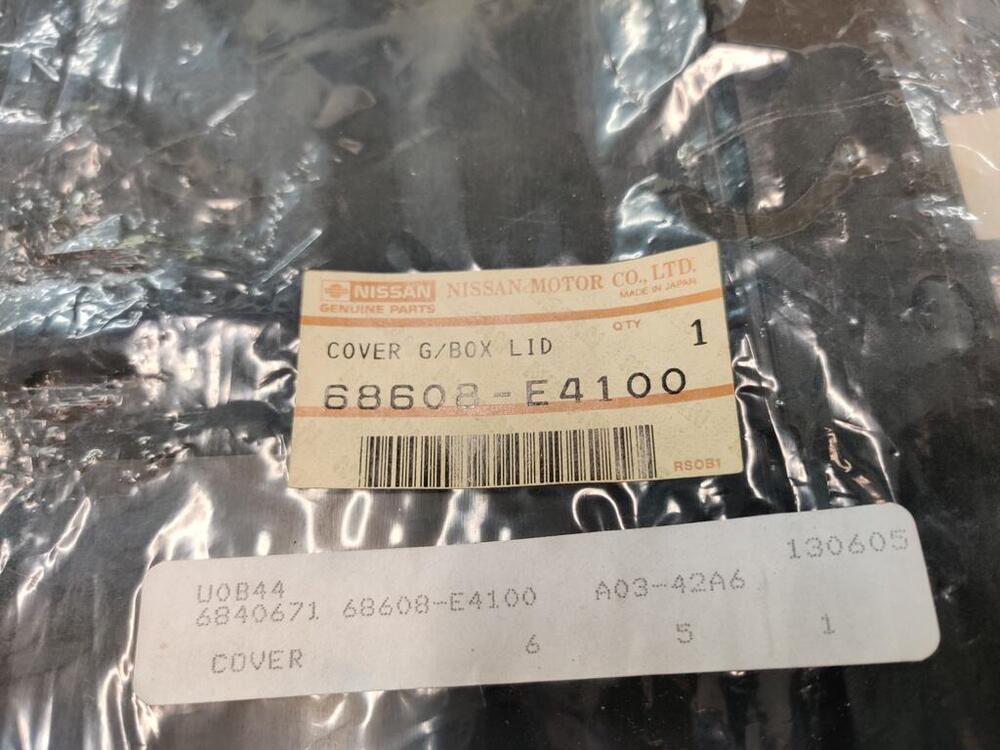

While I have turned much of my attention to my other 240Z recently, there are still quite a few things on the to do list for this car. One of them was replacing the glove box hinge/panel. My old one had broken at one of the three hinge areas. I was lucky enough to find a NOS one. Having recently replaced the decal on the original one with a new decal, I had to procure another new decal, and put in on this new panel. I still have some alignment issues to work out before the glove box will shut properly. The Vintage dash that is the car requires a bit of trimming of foam and vinyl on the lower edge of the glove box opening to allow the hinge to operate properly. Another small item on my list was to install these plastic seat belt buckle trim plates (old foam on the right, new on the left, which I glued to the center backside of the trim: These go here on the 1971 belts: I used a heat gun to warm them up quite a bit before snapping them into place, which went without issue thankfully. I still have a bunch of details like this that need to be completed. I would like to swap out the headlights bulbs for some other Koito H1 type ones that I found which look more like the originals. There are various other markings I'd like put in place to replicate factory ones (paint markings). I also would like to get the original wheels refinished and get some stock sized tires mounted on them. The original hub caps that I have are very nice, but if I can get better results with the paint color experimentation, matching the original much better than my efforts thus far, I will refinish them. I still haven't done anything to address the lean condition that I am experiencing. So, that is still on my list. After about 4 rounds of pulling the valve cover off to adjust the valves (the valve noise was much more than I can recall with my other L series engines), I figured out part of my problem. I have generally been adjusting valves with the engine cold, but sometimes when it was kind of warm as well. I was sure it would tighten up as the engine got warm. What I have found instead is the the lash clearance actually grows a bit when the engine warms up. The specification for my camshaft is .006" on the intake and .008" on the exhaust. I started off with setting the clearance at that spec with the engine completely cold. I then found that the lash was a bit larger with the engine lukewarm and a bit larger still with the engine hot. Seeing this, and after resetting lash a couple of times prior with no improvement, I decided to use .005" and .007" while the engine is cold instead. With that I achieve notable improvement.2 points- SN 00042 Restoration; The Older Twin

2 pointsMy now closed shop generated 4 Gold medallion stock 240 recipients. We tried 2 different finishes for exhaust manifolds. One was a finish like you're using and the others had Jet-Hot cast finishes. In EVERY case the judges (?) said the finish was incorrect and deducted points. Our last Gold Medallion car was judged (?) to have a steering wheel finish which was "too shiny". Go figure!!!2 points- SN 00042 Restoration; The Older Twin

2 points2 points- Just saying hello

2 points- Help ID early air filter assembly

2 points- [2025] What Did You Do To/with Your Z Today?

2 points- [2025] What Did You Do To/with Your Z Today?

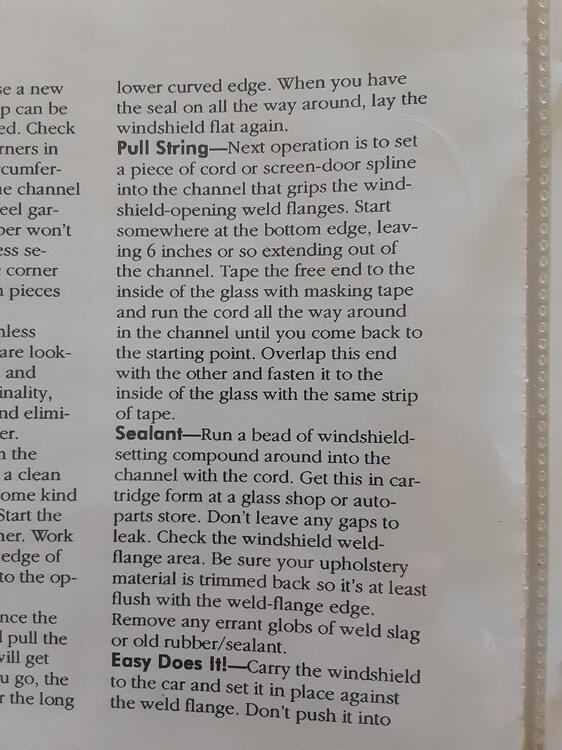

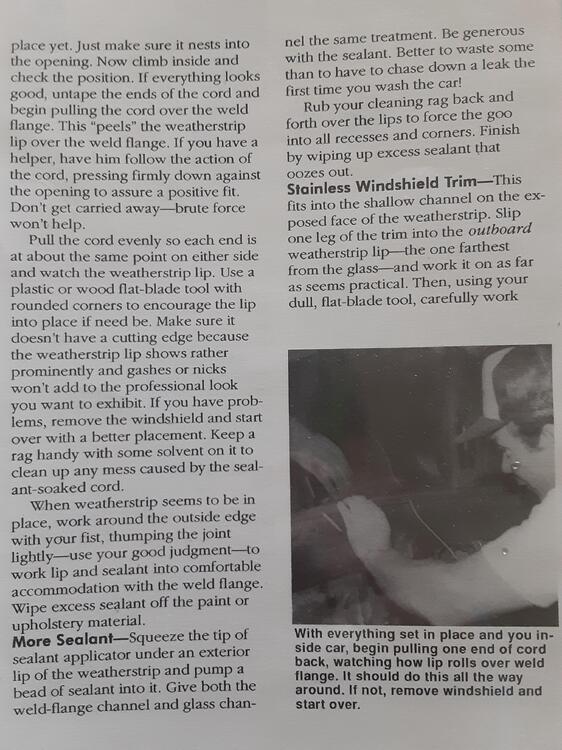

It did strike me as odd that Humble had you snug in the spline and then put a continuous bead of adhesive over it only to pull the spline out later. I can attest that this pulls out most of the adhesive as well. But, who am I to argue with a guy who did it this way and wrote the book on restoring a Z car? Attached photo of Page 130 shows exactly what he said to do. This was for the windshield but he later on says to do the hatch glass the same way. Then, at the bottom of the first column of Page 131 he says to do exactly as you say; i.e., put the sealant under the raised lip of the window. In fact, as I read it, he's saying to do this on all three channels: glass, exterior and interior. This makes eminent sense and really makes me wonder how that first bit of nonsense made it through editing. Oh well, live and learn. Frankly, it's stuff like what I've just been through that makes it all the more important that users of this site comb through all the old threads and extract useful info that can be condensed and put into technical articles for any and all to utilize. I'm trying to do that during my build. Final photo is of my pet Senegal parrot, Koki, eating the marrow out of a chicken bone; a favorite activity. He just loves attention.2 points- My two swiss S30Z Fairlady Restoration build thread

Recently I got two set of two of the missing Pieces from my 240Z toolbox. I had a set which fit the image, but had different part numbers. Funny enough, now i have three different sets, all have slightly different shape or surface. some have different numbers, but appear to be for the same purpose :-) Despite being a bit corroded, i have at least now another missing piece of the puzzle. Thanks a lot to @26th-Z for your support! I had some free time, so i decided to get some small stuff done on the car. First thing to check off was test-fitting the headlights. Luckily, I always have a range of NOS and used parts on hand. I usually try to use old parts for test-fitting, so I don't mess up new parts, but in this case the old ones weren't really usable. So here we go: NOS headlight buckets and chrome rings, with reproduction rubbers (I will use the NOS set for the final assembly). And installed. You got to love the factory stamps on shiny plated parts. As usual, all bolts are temporary only for the mock-up. For the final assembly, I will use original fasteners :-) I wasn't first sure if the order of the assembly was correct, but it appears it is. And the frog got some eyes, again :-) Next was this choke assembly reinforcement plat made out of hardened plastic: As the name suggests, it's there to reinforce the choke assembly, which is usually mounted on the inside of the center console, and can get a bit wobbly. With this plate, it's instead mounted on the transmission tunnel and way more stable. It's one of these (invisble) improvements of the car, which I think really give the car a better feel. It's quite tricky to place correctly, though. But luckily I had a few completely broken center consoles, so the easiest way was just to drill the holes through the console And then sandwich it all together for test fitting. I also installed an old ashtray just to see if it all still works correctly. Now with the holes on the transmission tunnel. I will not use the original sheet-metal screws but instead have nuts welded on the outside and use machine screws, so it looks like it's a factory thing, from the outside. And the interior mock-ups are coming along. Driver side seat rail, passenger side footrest and center console (With choke assembly) is installed and looks good. Ignore where the choke wires go. They're just there for easier installation.2 points- Z's on BAT and other places collection

It is buy it now for $40k. I told him to emphasize that the original mileage is 51k and to add some pics of his documentation... pics of the various VIN plates and VIN on the firewall, and pics of the engine number on the block and the E31 on the head. I see he has added the documentation and the engine compartment tag already. I know the market is a lot softer now for these than it was, but I think it will sell for the $40k.2 points- 1975 280z Build

2 pointsThe only change I would make to the excellent info above would be to use Marvel Mystery Oil. It contains mineral oil and a solvent that dissolves anything sticky or gummy.2 points- 1975 280z Build

2 pointsI would think the motor oil you're using squirted down the spark plugs holes would be good and take the valve cover off add soak the cam and valve train. Then turn it slowly clockwise from the the front and notice any hang ups or anything but smoothe rotation over and over. Leave the plugs out and use the starter but don't crank too long, short burst as to not burn the starter up. You will need a battery charger and don't rush the process, feel the starter and if it gets too hot to touch call it a day. The coolant should be all the way up to the top of the radiator fill hole. Let it run until you see the coolant flowing. I would add some water to your coolant, it looks to be straight antifreeze. That's not bad but 50/50 is what most people do.2 points- 240z air inlets

2 pointsFresh air intakes for the vents controlled by pull/push knobs under the dash near the driver and passenger kick panels.2 points- My two swiss S30Z Fairlady Restoration build thread

I was busy with sorting out some things in life, recently, so no big progress on the Car project side, aside from changing all family cars to winter tires. To keep my spirits up, the postal guy brought new stuff almost daily. The first was a nice delivery of an EU-spec front spoiler and a set of EU-spec front lower corner valances. Thanks a lot @HS30-H for your support, once again! One of them was even a NOS item with the Nissan stickers on it: Then, I also got a small delivery from 240Zrubberparts.com. I was looking for that KM-1520ZC replacement faceplates and I have to say it looks quite good. I was even gifted a set of label stickers for the radio, which I really appreciate. This will come in very handy when come to the planned restoration of the Radio. I hope to be back on the car project again soon. I've discussed a few next steps with a specialist and I hope the project gets a big boost next year, but I also hope to be able to finish a few things in the coming weeks.2 points- Told him to scrap it !

2 pointsAnd now he says - I’m out ! I had a hard time reading this guy but don’t think he was ever a serious Z owner/buyer . Good luck - I said Moving on2 points- Fuel Pump Hammer Smack

2 pointsDid you see where this thread ended up? Once the thread's purpose is served why not use it to have a conversation? Nothing wrong with that.2 points- Fuel Pump Hammer Smack

2 points- Told him to scrap it !

2 pointsNow the gentleman has requested I find him a Z ! He says his budget is 35-45k . I should be able to find something nice enough in that range I believe .2 points- 72 240Z Disassembled Project, ~95% Complete, Parts Boxed

I sold the car and apparently the buyer is sending it to England for restoration.2 points - Restoration of BringaTrailer 240z - HLS30-35883

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.