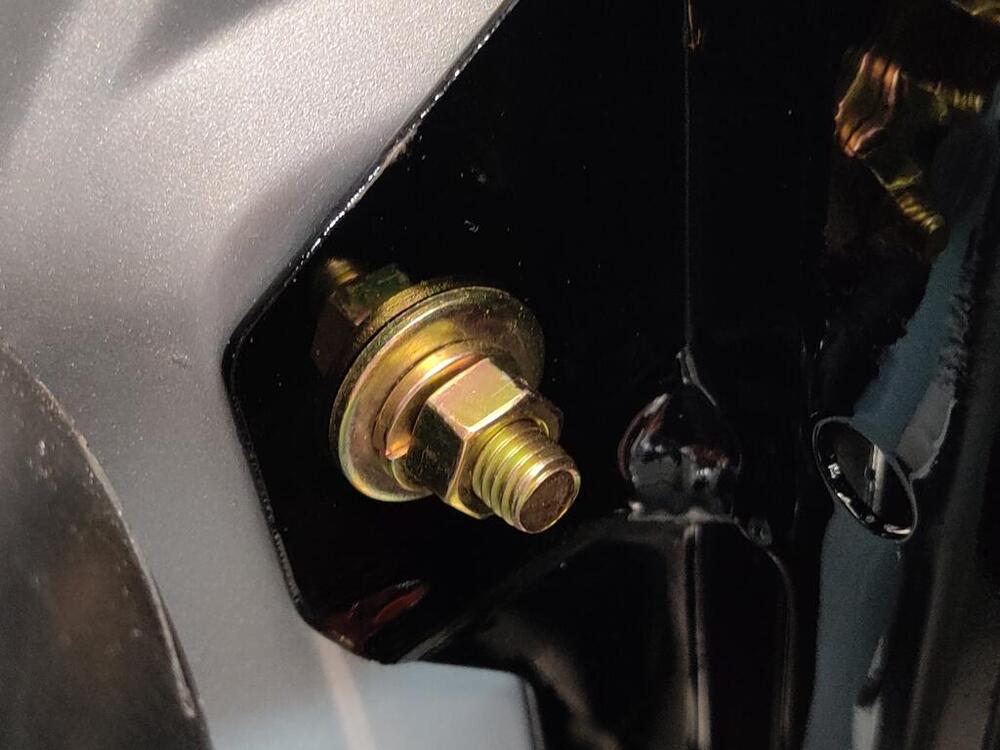

There is no pressure (other than weight of the fluid) in the transmission. Most people tighten both the fill and drain much tighter than they need to be. They only need to be as tight as not to leak. I used to recommend just using Teflon tape on the threads but now use Loctite 567 Thread Sealant and only tighten to snug or slightly past. (got pretty sick of having to use a 3 foot cheater bar to remove customers fill plugs and an impact on the drain...)

(I'm a journeyman plumber and spent 35 years cutting and threading pipe. Just like flare fittings, there's science to threaded pipe fittings - which the fill and drain plugs are - just like there's science to the dissimilar metals involved. Tightening a threaded fitting too much is as bad or worse than not tightening enough. "Pipe dope", Teflon, cutting oil (lubricant) it used to control heat caused by friction. Too much friction (heat) causes micro fractures in the metal of the thread which means leak. So, the Teflon is actually more of a lube than a "seal"... Also the more torque you put on it, the more friction there is, more heat to damage the metal. - There, I've given my unsolicited plumbing advice for the day!)