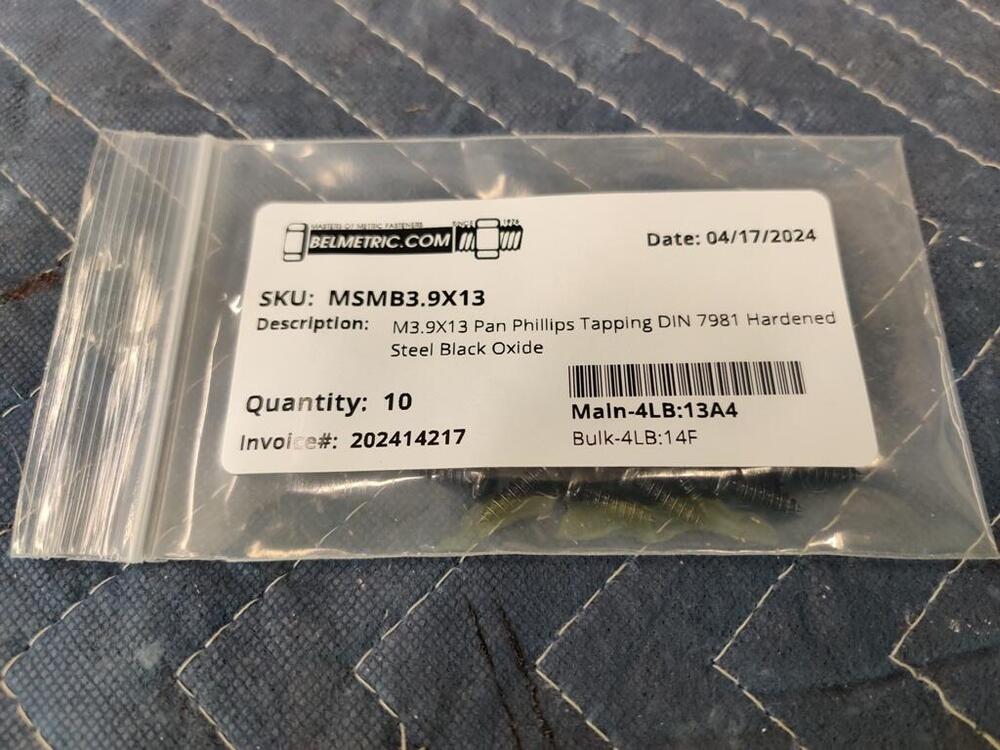

I couldn't find the original screws for the threshold plate, so I got these from Belmetric - some of the only non-original hardware anywhere on this car! 🙂

I have looked for many years for a 240z rear view mirror that doesn't show signs of corrosion on the edge of the glass, but haven't found any. I am thankful that @zspert sells an excellent reproduction:

Next step for the upholstery cardboard was to coat it in a rubber coating to keep moisture from causing it to lose its rigidity over time.

These are ready to glue into place now.

Speaking of gluing, I finished gluing the rear hatch main seal in place this weekend. I again used the yellow "landau" contact adhesive. I glued the four corners in place first. This seal is a bit small for the opening and requires stretching. So, gluing the corners first allowed me to put sufficient stretch into the rest of the seal. Then, it was a matter of using the acid brush to apply the adhesive in the remaining areas. This adhesive sets up in under one minute, and is super strong. I found that it was best to work in sections that were only about 18" in length. I would apply adhesive with an acid brush on the weld flange as well as the backside of the weather strip, then wait about one minute. As soon as I put the two together, it sticks, and goes nowhere. Great stuff to work with.

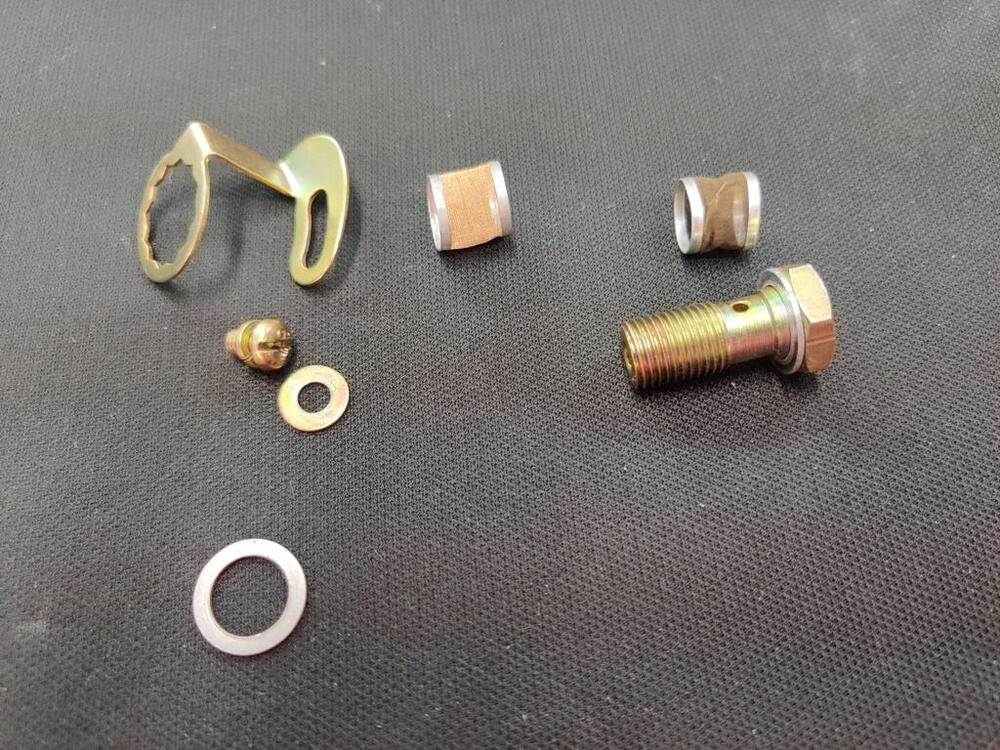

I started to install the fuel hose in the engine compartment. Before doing so, I checked to see if the carburetors had inline fuel filter screens. The front carb did not, and the back carb did. I installed new ones. I have to check that the floats are set correctly, so I elected to hold off on installing the hoses that go from the fuel rail to the float chambers. I did install the hose to and from the fuel filter. Hose is cloth covered; the closest thing I could find to original.

Can anyone confirm the hose clamps I am using here are correct? I think that the clamps at the filter are supposed to be spring clip type... while the connections at the hard line and fuel pump inlet are supposed to be the zinc plated hose clamps as seen here:

I also got all the bumper pieces packaged up. I will be sending them to Tri-City plating to get them redone.

Subscriber

Subscriber 5Points11,142Posts

5Points11,142Posts Subscriber

Subscriber 4Points1,282Posts

4Points1,282Posts