I just re-covered my passenger seat with the Interior Innovations cover that I bought from @KenFirch a while back. I purchased the replacement foam from Interior Innovations as well. I wasn't really looking forward to the job. It sounded like it was a bit of a pain, but it went very well and didn't take me more than a couple of hours. I thought I'd add a couple of things to this thread that might help people doing it in the future.

My car is a 1971 240 (the one @grannyknot has been working on in a current build thread), but the seats seem to be from a 280Z. They have the metal "springs" in the seat bottom rather than the webbing. They've been recovered previously (the covers were obviously not original), but the foams seemed to be original. A couple of things made the job easier, as described here.

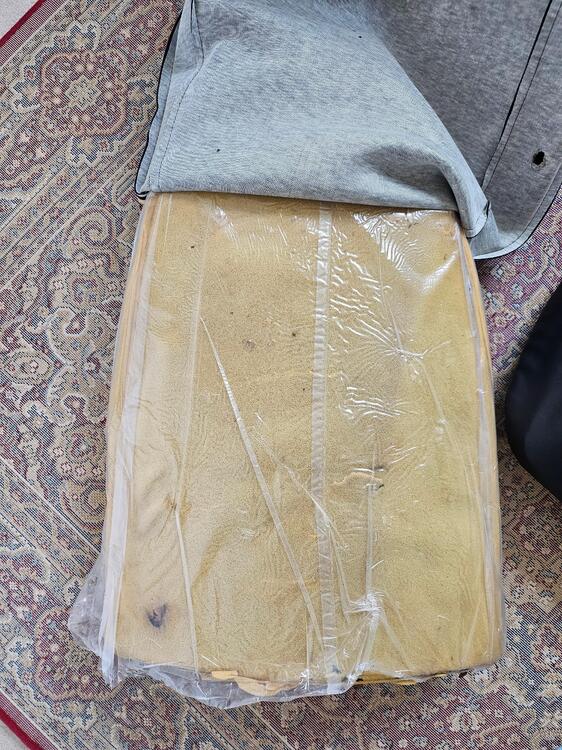

There was a thin sheet of plastic covering the foam of the seat back. It seemed to be professionally made to fit the seat, but I don't know whether it was something that came from the factory. It was a little worse for wear, but I was able to reuse it. I was also able to leave the very thin layer of foam on the metal seat back. It was wrapped around and over the edges of the foam on the front of the seat back, but I was able to peel it off.

I first glued the edges of the new foam to the metal seat back. I used Lepage Multi-Purpose Spray Adhesive and it held very well through the rest of the work. The plastic on the top of the seat back made it easy to slip the top of the new cover over the seat back down to the point where I needed to hog ring it to the metal back. Once I'd done that (more on that in a minute), I was able to very easily roll the rest of the cover down over the rest of the back. When using the tangs to secure the front and back of the cover to the bottom of the seat back, it was easy to pull the material down far enough. This was probably because it could slide easily on the plastic sheet.

I was able to hog ring the cover to the metal back through the slot without too much trouble. I first used plastic cable ties to pull the wire on the metal seat back and the wire in the seat cover insert together, then used the hog ring pliers I bought to add the hog rings. I was going to cut the cable ties off afterwards, but decided to simply trim them instead. I can't see them doing any harm, and they're providing extra holding power.

When I did the seat bottom, I first used the tangs to pull the cover down tight on the foam and metal seat base. Once I'd done that, it made the job of attaching the hog rings much easier because the foam was quite compressed. I used the cable ties again, which made it very easy to attach the hog rings. I do kind of wonder whether you could do this job with the cable ties and not bother with hog rings at all. Maybe they'd wear through over time.

So I would suggest using a plastic wrap over the seat back, attaching the seat bottom cover using the tangs before doing the hog rings, and using cable ties to pull parts together when installing the hog rings.

I'll be doing the driver's seat over the next few days, so I'll get a chance to do this again. Hopefully it will go as well as this one did.

Subscriber

Subscriber 5Points1,935Posts

5Points1,935Posts Subscriber

Subscriber 4Points11,142Posts

4Points11,142Posts